There has been a lot of buzz since the 2015 Ford F-150 – largely comprised of aluminum – was released. And rightly so! It’s likely that body shops are going to see a fair share of these vehicles in their bays. However, this is not brand-new technology; body shop techs have worked with a lot of aluminum car parts for many years.

Be that as it may, it’s likely we’re going to see more of the stuff in the not-too-distant future, thanks in part to the CAFE standards as well as the abundance of aluminum. (CAFE: Corporate Average Fuel Economy – Enacted by Congress in 1975, the purpose of CAFE is to reduce energy consumption by increasing the fuel economy of cars and light trucks.) It’s the most common metal on the planet; in fact, it’s the third-most abundant element. That’s not news, but what is news is the upswell of approved repair equipment on the market. There’s going to be less remove and replace and, naturally, more repair. And the repair process is different for aluminum than steel, just as it’s different for fiberglass. And while shops will no doubt adapt to aluminum, just as they did for fiberglass, there are genuine concerns that go far beyond getting “itchy.”

CORROSION

Corrosion. Galvanic corrosion. Electrolysis corrosion. Dis-similar metals corrosion. Whatever you call it, there’s no sacrificial zinc anode we can introduce to render cross contamination inert. Prevention is the key. It is imperative to have a clean room, separate dedicated tools, exhaust systems, etc.

There are also health concerns. Not to be taken lightly, excessive aluminum absorption, whether by dust or fume, has been linked to cognitive degeneration and brain disease in some studies. I would take it seriously.

PAINT SHOP

Now, back in the paint shop, there are things for us to consider. You need dedicated tools, sanders and blocks. Furthermore, you must maintain a quarantined environment in an effort to prevent fraternization between the metals. I doubt it would lead to a door falling off its hinges if cross contamination happened in the paint shop, but it will lead to paint failure. And I assure you, down at the “forensics lab,” if you file a paint warranty claim that stems from this, they’ll uncover poor and improper work practices that will void any warranty. So, check with your jobber or supplier and invest in another mobile work station/cart that’s strictly “aluminum.” Aluminum refinish failures, like all refinish failures, are avoidable.

REFINISH PROCESS

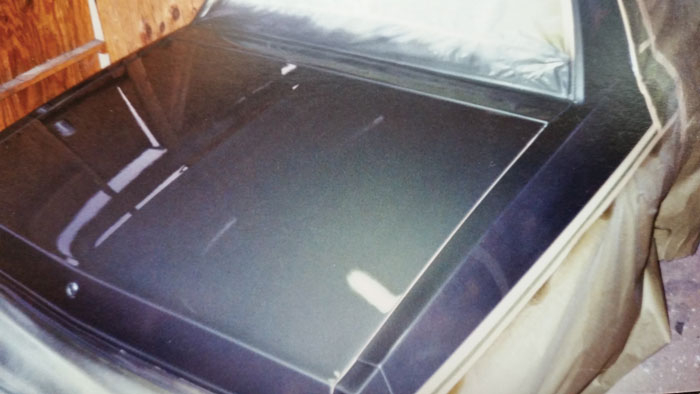

Presuming we’re all on the same page with understanding the need to isolate these two siblings, aluminum and steel, the refinish process is remarkably similar. Clean, abrade, clean, condition/etch, prime/seal and paint. Any questions? OK, perhaps that’s oversimplifying it, for there are substrate-specific products that must be utilized to ensure success.

If we consider a new OEM part first, not much changes. You can prepare the part according to your specific paint line practices and proceed with sealing, provided you haven’t “cut-through” the e-coat and exposed the aluminum. In most instances, minor cut-throughs on steel panels can be safely sealed over. However, you’re going to have to apply an etch primer to cut-throughs on aluminum panels prior to sealing. The good news is that you can use a 1K aerosol product, being mindful of flash-oxidation and etch-prime immediately after abrading and cleaning. Keep in mind, though, that a 2K etch primer is superior.

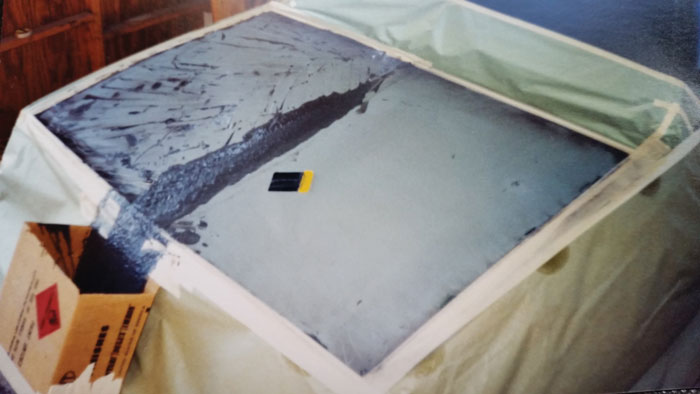

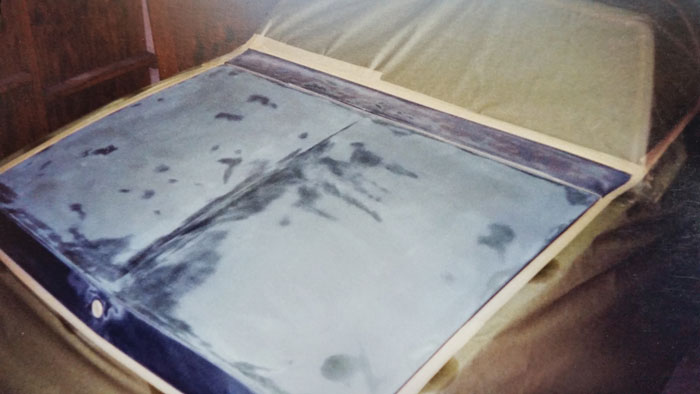

Larger areas of bare aluminum will require a different cleaning approach. First, utilize a wax and grease remover to eliminate any surface contaminates. Minimize sand scratch patterns to a 240 or finer grit on your DA. Next, use an aluminum-specific metal conditioner/cleaner, according to the manufacturer’s specifications. When rinsing off the conditioner with water, look for the water to “sheet off” as opposed to beading or channeling. This is known as the “water break test,” and a properly cleaned panel will sheet the water. Beading or breaking indicates a presence of wax or grease.

Dry thoroughly and apply an aluminum-specific metal conversion coating. This will stabilize and modify the surface while offering a layer of corrosion protection. Do this immediately after drying, as aluminum will oxidize/corrode rapidly. The conversion coating will typically have fantastic corrosion resistance and adhesion properties. In many cases, it can be directly sealed or primed over, depending on the nature of the repair, but again, the use of a 2K etch primer prior to sealing or priming will provide a film build with greater integrity.

BARE STEEL

I know from firsthand observation that not all painter/preppers are addressing the issue of bare steel properly. I believe the uptick in aluminum education presents an opportunity that can be leveraged into a greater awareness and understanding of flash rusting, proper cleaning, conditioning and coating of steel as well. As stated earlier, the standard operating procedures surrounding aluminum and steel preparation and coating are surprisingly parallel. It’s those initial products and coatings that will vary, so talk with your jobber and tech reps. Get educated and prepared! Be proactive in both education and product use, which will pay off through uninterrupted production.

ANOTHER OPPORTUNITY

Lastly, the galvanic corrosion is real, and the potential health hazards are real. With what we know regarding these two subjects, there is no reason whatsoever for either of them to pose any kind of challenge or problem. The information is here. The tools are here. The educators demonstrating proper procedures are here. The industry has risen to the ever-changing challenge. It’s up to us, individually as well as collectively, to ensure we’re performing qualified and safe repairs. In all honesty, I suppose there is no aluminum conundrum at all, simply another opportunity.