It looks as though Ford is going to be bringing back the 6.8-liter Triton V10 for 2017. Much to people’s surprise, the V10 actually never stopped production. Many thought that the Triton was no longer available when Ford quit offering the engine as an option for the 2011 Superduty. However, the V10 has been offered as an option for the F450-F750 cab and chassis along with motorhome chassis since 2012. With the introduction of the 6.2-liter V8, the V10 was simply dropped from the Superduty line.

It looks as though Ford is going to be bringing back the 6.8-liter Triton V10 for 2017. Much to people’s surprise, the V10 actually never stopped production. Many thought that the Triton was no longer available when Ford quit offering the engine as an option for the 2011 Superduty. However, the V10 has been offered as an option for the F450-F750 cab and chassis along with motorhome chassis since 2012. With the introduction of the 6.2-liter V8, the V10 was simply dropped from the Superduty line.

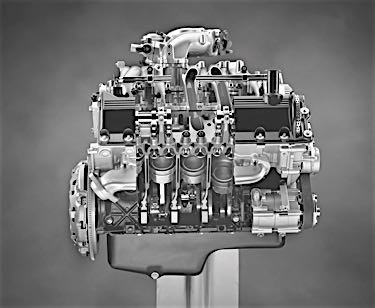

The V10 has been an option for the Ford truck chassis since 1997. With the elimination of the 385 series 460-cubic-inch big block, Ford offered the V10 as a diesel alternative. The V10 is a part of Ford’s modular family, and is actually identical to the 5.4-liter SOHC with a 3.552˝ bore and 4.165˝ stroke with the addition of two cylinders.

The two-valve version, which produced 310 horsepower and 425 ft.-lbs. of torque, was offered on 1997 through 2004 models. The three-valve version was offered on model year 2005 through present vehicles with 360 horsepower and 457 ft.-lbs. of torque. The crankshaft is unique with a split pin for 72° firing intervals (with a firing order of 1-6-5-10-2-7-3-8-4-9) and a balance shaft placed in the driver’s side cylinder head to help in dampening vibrations.

With a life expectancy of 300,000-plus miles, the V10 has offered great service and reliability. These engines are reasonable to rebuild and have a variety of aftermarket parts available for them.

One thing to keep in mind would be the initials “PI” cast into the cylinder heads. These initials stand for “Performance Improvement.” Early versions of this engine from 1997 until 1999 were considered “Non-PI.” The PI versions started in 2000 and incorporated changes to the cylinder head and intake manifold, which resulted in significant power gains for the engine. The intake manifold and cylinder heads of PI engines will not interchange with Non-PI engines due to differences in port design.

Cylinder Heads

The F7VE head, known as a Non-PI version, was produced from 1997 until 1999. These have rounded intake ports with an open-style combustion chamber with one intake valve and one exhaust valve.

The YC2E head was produced from 2000 until 2001 and is known as a PI version. It has somewhat of a square-shaped intake port with more of a closed-style combustion chamber that offered a small compression ratio change. Also, it has one intake valve and one exhaust valve.

The 1C2E was produced from 2002 until 2004 and known as a PI version. It has the same head as the YC2E with differences in the spark plug threads. The 1C2E cylinder head is often referred to as a LP, which stands for “long plug.” These heads had revisions to the spark plug threads because Ford had issues with the Modular engines (meaning the 4.6 liter and 5.4 liter) prior to this that would blow the spark plugs out. The problem was that there were not enough threads holding the spark plugs in the cylinder heads.

Over a period of time, the spark plugs would work loose and then blow out, stripping the threads from the cylinder head. There is a service tool and procedure for the prior cylinder heads that will ream the stripped spark plug hole to allow for a new threaded insert for the spark plug.

The 5C3E was produced from 2005 until 2007 and signaled the introduction of the three-valve version. This head had two intake valves and one exhaust valve. The spark plugs changed to a different design for the three-valve combustion chamber. The intake ports are an oval shape for the split port design of the two intake valves.

The 9C3E is the latest head (produced from 2008 until present) and is very similar to the 5C3E except for a smaller combustion chamber that results in a small compression change. From 1997 until 2005, the two-valve cylinder heads used a spark plug with a 14 mm thread, an 18 mm reach and a 5/8˝ hex. The valve diameters were 44.5 mm for the intake valve and 36 mm for the exhaust valve.

From 2005 until present, the three-valve cylinder heads used a spark plug with a 12 mm thread, 26.5 mm reach and a 9/16˝ hex. The valve diameters were 34 mm for the two intake valves and 37.5 mm for the one exhaust valve.

Head bolts are torque-to-yield (TTY), meaning for one-time use. The two-valve and three-valve versions require different part numbers for replacement head bolts.

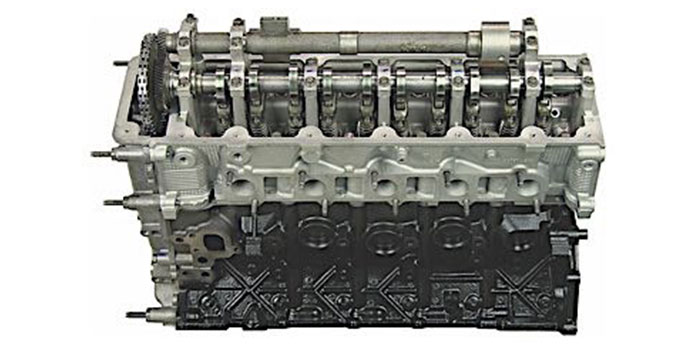

Engine Blocks

The blocks follow the same evolution as the heads. The biggest change was the 1C3E block that was in production from 2001 until 2003. It was produced for PI cylinder heads and had knock sensor bosses in the engine valley. Keep in mind that you may find that some blocks will have the knock sensor bosses machined and some will not be machined. The 3C3E block was in production from 2003 until 2005, it was produced for the PI cylinder heads and should have machined knock sensor bosses in the valley of the engine, as would all later models.

The PI cylinder heads used a PI intake, which had a shallow plenum versus the Non-PI intakes. The Non-PI heads cannot be used with latest version block because the deep plenum of the intake will hit the knock sensor bosses in the valley of the engine.

There are various types of intakes for these engines based on their applications. Some intakes are aluminum and some are plastic. There are differences in designs used between truck and van applications. The important thing to remember is there is not only a difference in port designs for Non-PI, PI and three-valve versions, but also for the depth of the plenum.

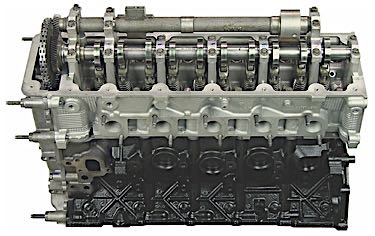

Chains and Tensioners

The timing chains and tensioners were the same for all years of production. Non–PI engines produced from 1997 until 1999 take a different camshaft from the PI versions produced from 2000 until 2005. The three-valve-per-cylinder versions produced from 2005 until present also required a different camshaft. Keep in mind which version you have when purchasing a new camshaft and remember that there are separate part numbers for the left-bank and right-bank camshafts.

Oil Pump

The same gerotor-style pump was used for all years of production. In June 1996, Ford manufactured the first Triton 6.8-liter V10 at the Windsor Engine Plant. The Triton V10 was added to the same production line as the 4.6- and 5.4-liter engine because they all could be built on the same line.

Article courtesy Underhood Service.