This article is courtesy of Body Shop Business.

n today’s “material world,” it’s an understatement to say that aluminum repairs are entirely different than those involving steel. Simply put: For a complete, safe and quality repair, it’s vitally important to understand the vast considerations involved with repairing aluminum.

As an example, let’s look at an aluminum panel dent repair and apply some critical considerations to emphasize the technical knowledge and skills involved in the repair process.

Repair Procedures

First and foremost, be advised that various OEMs have different rules/repair procedures when working with aluminum. Just because you’re trained or certified with a particular OEM does not mean those same considerations can cross over to another automaker. While this can be frustrating, it’s important to note this current inter-industry reality.

Different Grades

Aluminum, like steel, has different grades and characteristics that determine strength and repairability. Aluminum is graded in seven different series, so knowing what series you’re working with is important when determining repair plans and procedures.

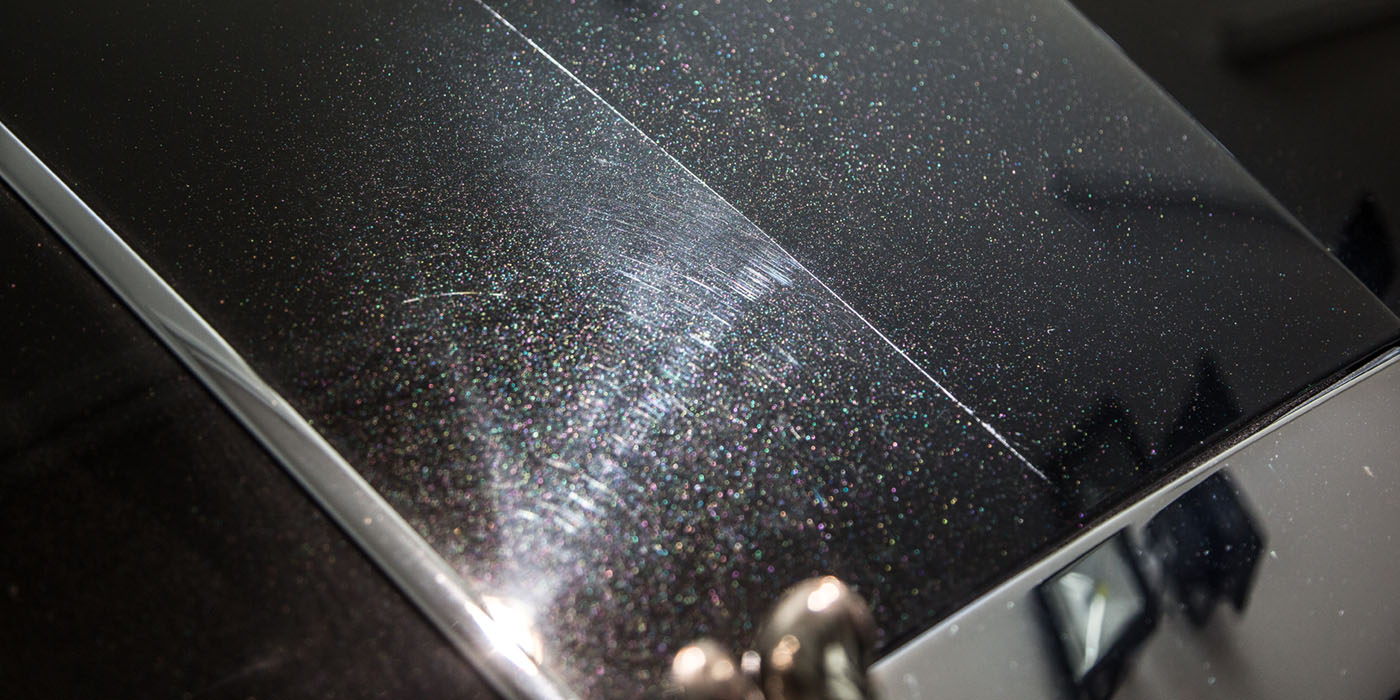

Corrosion

When working with aluminum, things to consider during repairs are galvanic corrosion and cross contamination. It’s critical to keep steel and aluminum parts separated during a repair to avoid any particulate contact between an exposed bare metal body panel in the surrounding area. For this reason, you should use a separate/designated room for any and all aluminum repairs to prevent galvanic corrosion and cross contamination from occurring.

When it comes to aluminum, there simply are no shortcuts.

Aluminum and steel dust particles can float in the air and remain there for hours, making their way onto any exposed panels throughout the repair facility and causing cross contamination between metals. For instance, a tech can be sanding a steel panel across the repair facility, and particulates can “float over” and land on exposed aluminum panels — and you would never even see this happen. Also, let’s say you’re working on an aluminum door and an adjacent steel quarter panel repair needs to be repaired. In this situation, the aluminum door should be removed from the vehicle and taken into a separate, designated aluminum area, so no cross contamination can occur.