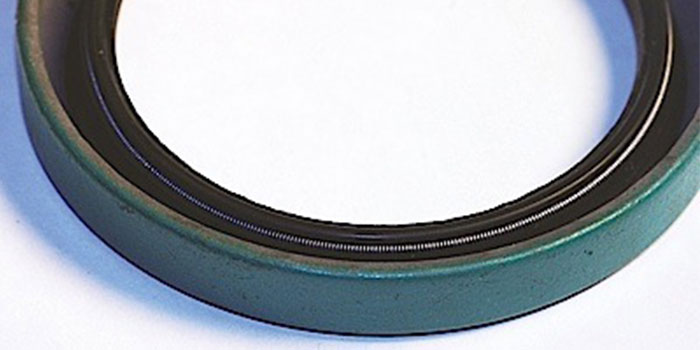

Understanding Wheel Bearing Seals

A seal must always be installed so that the sealing lip is facing the fluid to be sealed. This is because the lip is made so that pressure applied to it from the “wet” side of the seal will tend to increase the pressure the lip applies to the shaft. If the seal is installed backwards, pressure acting on the “wrong” side of the lip will cause it to lift from the shaft, resulting in leakage. On most seals, the correct side is obvious; however, on others it is not.

Drivetrain Noises & Wheel Bearing Replacement

Some of the toughest challenges import specialist techs face are noise complaints. And, in order to make an accurate assessment, we take the time to ask our customers questions like: Is the noise present when the car’s stationary or moving? Does it change around corners or under different load considerations? Is it a growl, squeak, groan or rattle?

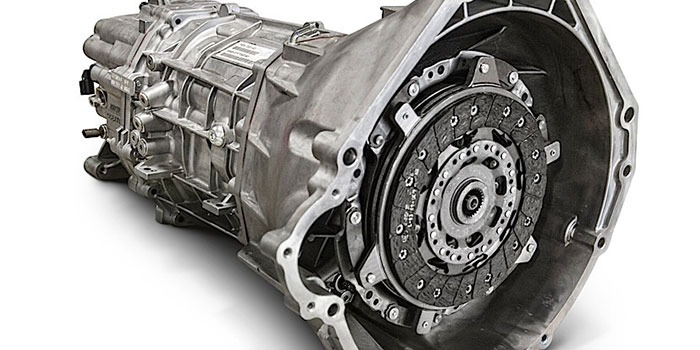

Complete Clutch Replacement: No Noise, No Comeback

Diagnosing clutch and manual transmission noise can be a difficult diagnosis. There is no way of attaching a scan tool or looking into the bellhousing while the clutch is under load. Clutch diagnostics requires logic and understanding of how the parts interact.

Tracking Down Honda Chassis-Related Noise Complaints

For this article, we find ourselves under a high-mileage V6 Honda Accord looking for what should be an easy-to-find knocking noise. When the car was written up at dropoff, notes were added for the tech to look for loose sway bar links and bushings based on the customer’s description of a knocking noise over bumps.

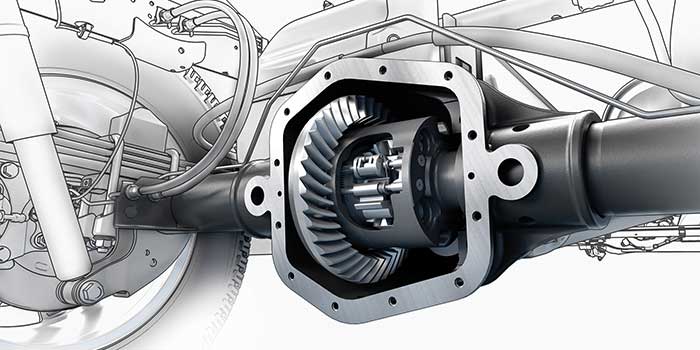

Live-Axle Wheel Bearing Replacement

Replacing wheel bearings on a vehicle with a live rear axle may not be one of the most frequent jobs, but it can be one of the most profitable. While the basics have not changed in more than 60 years, new seal materials and differential designs have added new wrinkles.

Lessons in BMW Variable Capacity A/C Systems

Despite the many advances in A/C systems during the past 10 years, it’s important for technicians to understand basic theories of operation. Understanding how a system moves heat from the confined space of the passenger compartment and dissipates it into the atmosphere will assist the technician in analyzing system failures and performing the required maintenance

Bearing Straights – Diagnosing Brinelling And Non-Noise Bearing Failures

In the good old days, most serviceable wheel bearings were maintained at least every 25,000 to 30,000 miles during a brake job. During this process, the races, stub axles and cages could be inspected for damage and replaced, if necessary.

Undercover: Subcompact Vehicle Upgrades — A Reduction in ‘Class Size’

Over the next decade, it would appear that we will see a shift to smaller, lighter and more fuel-efficient vehicles, much like we experienced in the 1970s.

Undercover: Handling Honda Brake Systems

What we’ll look at in this article is not so much how to replace worn-out pads, but rather things to be on the lookout for that will ensure a quality job and eliminate comebacks.

Component Connection: Noise Reduction — Replacing a Cartridge Wheel Bearing

While wheel bearing noise is one of the toughest problems for the customer to describe, it’s not unusual for it to come on so gradually that the customer may not even notice it until you mention it after an unrelated road test.