Your Guide To The Kia Brake Job

If a Kia comes in with a grinding problem, the next step is to look for uneven wear. If one wheel is showing more wear than the other on that axle, it’s time to do some investigating. The most likely cause of unexpected wear is a caliper or hardware issue, and the key to a successful job is figuring out the true culprit.

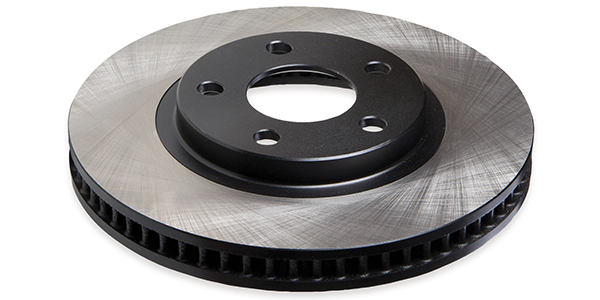

Change Your Mind When It Comes To Rotor, Pulsation Comebacks

How do you handle a pulsation or comeback? Blame the pads? The driver? Defective rotor?

Bosch Automotive Parts Center Dedicated at Southern Illinois University Carbondale

Center named in honor of Bosch financial gift to SIU Automotive Technology Program; Facility will serve as hub to connect students to public.

Lessons in BMW Variable Capacity A/C Systems

Despite the many advances in A/C systems during the past 10 years, it’s important for technicians to understand basic theories of operation. Understanding how a system moves heat from the confined space of the passenger compartment and dissipates it into the atmosphere will assist the technician in analyzing system failures and performing the required maintenance

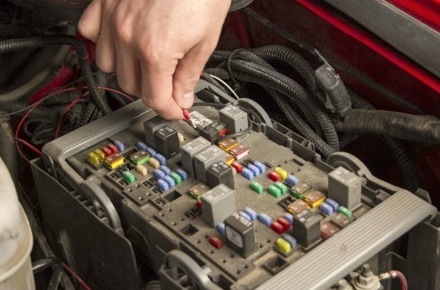

FAQs on Engine Programming: Tips for Tuners

What are they? How do they work in conjunction with the engine? Do they really improve performance and gas mileage? Sounds easy, doesn’t it? Just drop in a magic “chip” and your car or truck suddenly takes on NASCAR-like qualities ─ able to accelerate quicker or even achieve better gas mileage. Too good to be

Brake Job: 2000-’06

The third-generation Hyundai Elantra is the vehicle that put the Korean automaker on the map. With a roomy interior and a reliable drivetrain, the Elantra sold well to a wide demographic of import and domestic buyers. The brake system, for the most part, is generic and not difficult to service. In this article, we’ll be

Recognizing Runout And Disc Thickness Variation – Tips To Decrease Comebacks

Replacing rotors on every brake job is not a cost-effective or efficient way to perform brake service.

Bearing Straights – Diagnosing Brinelling And Non-Noise Bearing Failures

In the good old days, most serviceable wheel bearings were maintained at least every 25,000 to 30,000 miles during a brake job. During this process, the races, stub axles and cages could be inspected for damage and replaced, if necessary.

Undercover: Handling Honda Brake Systems

What we’ll look at in this article is not so much how to replace worn-out pads, but rather things to be on the lookout for that will ensure a quality job and eliminate comebacks.

Component Connection: Noise Reduction — Replacing a Cartridge Wheel Bearing

While wheel bearing noise is one of the toughest problems for the customer to describe, it’s not unusual for it to come on so gradually that the customer may not even notice it until you mention it after an unrelated road test.