Courtesy of Transmission Digest, by Wayne Colonna

Sometimes you’re the windshield and sometimes you’re the bug—a phrase many of us have heard and experienced. It’s inevitable. The idea is to be the windshield as much as possible. Shane from Cottman Transmissions had a helluva day but in the end, he was the windshield.

In his shop he had a 2016 Explorer using the 6F50 transaxle, sporting a P193F code for an intermittent vehicle speed signal. The pinpoint test Ford provides for this code are step-by-step instructions on checking the power, ground and signal wires this hall effect output speed sensor uses inside the transmission. These wires go to the solenoid body lead frame. The circuits then pass through the lead frame to the harness connector going to the PCM. The Pinpoint tests are looking for bad connections, short to ground, short to power or open circuits.

If a wiggle test and the internal and external wires pass their inspection, the sensor is replaced. And this is just what Shane did, yet the problem persisted. Since new does not necessarily mean good, another sensor was installed along with a solenoid body lead frame. This, too, did not resolve the problem.

At this point Shane took time to scan through different modules viewing their PIDs. When he got into the ABS system, he saw the right rear wheel speed stuck at 158 MPH—even at a stop. He decided to unplug the left rear wheel speed sensor to see what its PID would do. And when he did, it went to 158 MPH as well. This apparently is a default setting when there is an open circuit. After replacing the right rear wheel speed sensor (see figure 1, above, and figure 2 below), his problem was resolved.

The reason for the right rear wheel speed being the offending sensor is that the PCM uses the OSS RPM signal from the transmission, and the wheel speed signals from the ABS to calculate vehicle speed. With this sensor malfunctioning, it affected the PCM’s vehicle speed calculation, revealing itself as an intermittent signal loss. When P193F is set, there needs to be a companion code set with it—either an OSS code or a wheel speed sensor code. With this wheel speed sensor not coding like it should have, it made this a bit more challenging for Shane to resolve.

62TE troubles

The next troublesome vehicle in the shop that needed to be resolved was a 2015 Ram Promaster 2500 3.6L using the 62TE transmission. It originally came in with these following codes:

- C1221 – PCM BUS Signal Invalid – BCM not receiving messages from the PCM for approximately two to five seconds.

- P0365 – Camshaft Position Sensor Circuit Bank 1 Sensor 2

- P083B – LC Pressure Switch Rationality

- P1745 – Transmission Line Pressure Too High for Too Long

- P2764 – TCC Pressure Control Circuit Low

The transmission needed attention which included a new solenoid pack, TCC solenoid and pressure sensor. After it was overhauled and installed, some codes were cleared but codes C1221, P0365 and P1745 remained. After verifying power and grounds at the PCM, it was replaced. When the system was checked for codes, only P0365 remained.

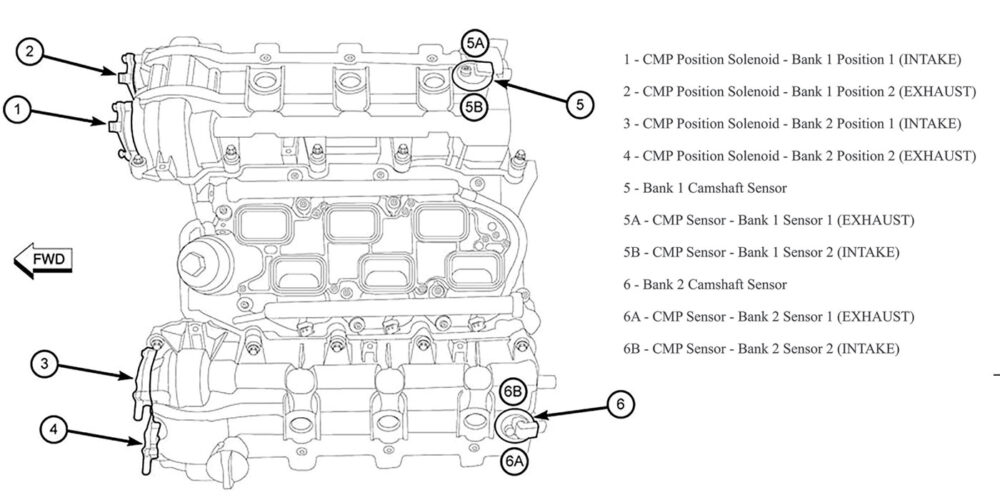

On a road test, the transmission would not shift into sixth gear. Since malfunctioning cam and crank sensors have been known to prohibit and overdrive shift in other vehicles, this sensor was ordered. The information they were looking at from an online service said the right front of the engine is where this sensor is located. When the sensor arrived, it didn’t match what was in the front right side of the engine which was the CMP Solenoid Bank 1 Position 2 (figure 3).

This solenoid is used to control the camshaft phaser. They then ordered and installed this solenoid only to have the same no shift into sixth gear concern. After looking at a different source for information, they found the correct location for CMP Sensor Bank 1 Sensor 2. It was buried and out of view. After finding it and replacing it with the new one they already had, sixth gear returned.

It was a helluva day for Shane, but he left the shop that day being the windshield and not the bug!