Number 06-68-19R

Models

All

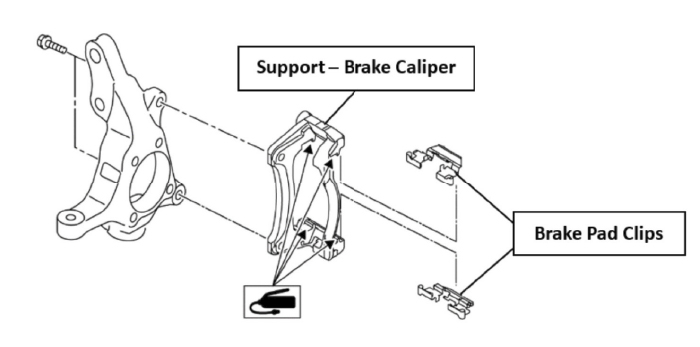

This technical service bulletin from Subaru covers the application of additional lubrication between the brake caliper support and pad clips. In the version, the brake grease is applied to caliper bracket and the abutment clip is then installed.

This will prevent the pad from dragging due to corrosion buildup which may result in uneven or premature wear of the replacement brake pads. This additional instruction applies to all models with brake pads using the upper and lower pad clips.

The illustration shown is from a 2019 Forester. The procedure below is applicable when replacing either front or rear brake pads.

Before installing new brake pads, remove the pad clips and thoroughly clean the caliper support of any dirt, rust, or corrosion, paying close attention to the areas where the clips are attached / seated.

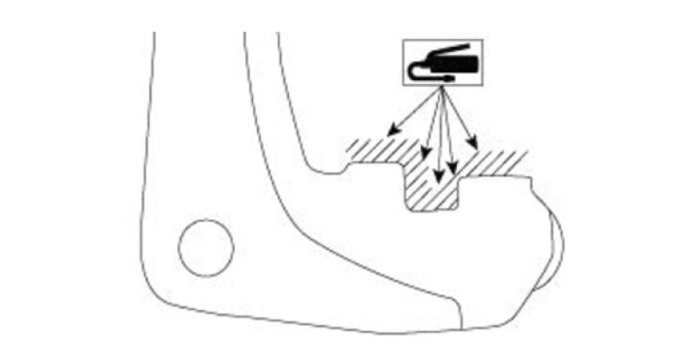

Apply a thin coating of brake grease to the caliper support then refit the pad clips to the support.

Apply a thin coating of brake grease to the ends of the new brake pads where they contact the pad clips.