Diagnosing Brake Roughness For A Lasting Repair

Warped rotors are probably one of the most common complaints from drivers coming into any shop that does brakes. The less confident or sophisticated driver may complain that when he hits the brakes, “the pedal pulses,” “the vehicle chucks during a stop,” or “it shakes my teeth during braking.” Generally, a quick turn of the

Hunting Down ‘Mysterious’ Steering Linkage Culprits

Steering system noise complaints can often be difficult to reproduce and diagnose. A squeaking noise in the steering column, for example, can often be influenced by temperature and humidity. In other cases, a squeaking noise can be caused by dry or corroded universal joints in the steering intermediate shaft located between the steering shaft and

GM Late-Model Brake Job

GM currently has about eight active vehicle platforms in North America, and many of these platforms share foundation brake technology and systems, like ABS and parking brakes. Compared to the previous generation of GM vehicles, these brake systems are more robust, yet more precise, and focused on reducing brake noise problems. Nearly every GM passenger

Undercover: Hybrid Brakes

A hybrid vehicle is a different animal than many of us are used to seeing. After all, if the engine of a typical vehicle stalled out at a traffic light, the driver of that vehicle would know something was wrong with it. If that same vehicle still drove with the engine off, then that would

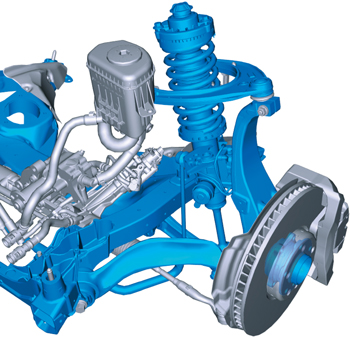

Front and Rear Spring Replacement

Springs and struts are prone to a few suspension issues, especially in harsher northern climates. The front strut bearings can start creaking, and then bind up, and we’ve seen more than a few front and rear coil springs break due to corrosion. So, let’s discuss what you can look for when you encounter one of

Going Undercover on Mitsubishi Undercar Service

Let’s take look at the Mitsubishi line of cars and some of the more common problems you’ll see while investigating the undercar area.

Tips on Choosing the Best Ride Control for Customers

Shocking Evidence During the fall of 1989, when I was working as a mechanic for an off-road desert racing team, we raced the famous Mint 400 held in Las Vegas. At that time, the 400-mile road course consisted of bumps, jumps and basketball-sized rocks just waiting to break a suspension system. About 50% of all

Undercover: Shimology 101 — Breaking Down Brake Noise

High-quality brake shims are frequency and temperature engineered multi-layered products using varying grades of metal, viscoelastic polymers/bonding materials, elastomeric rubbers and fiberglass to reduce vibrations.

Undercover: How Vehicle Software Is Changing Braking Hardware

There was a time when advancements in brake technology were entirely hardware based. Today, electronics is driving most of the advancements in braking technology.

Bearing Straights – Diagnosing Brinelling And Non-Noise Bearing Failures

In the good old days, most serviceable wheel bearings were maintained at least every 25,000 to 30,000 miles during a brake job. During this process, the races, stub axles and cages could be inspected for damage and replaced, if necessary.

Recognizing Runout And Disc Thickness Variation – Tips To Decrease Comebacks

Replacing rotors on every brake job is not a cost-effective or efficient way to perform brake service.

Undercover: Deciphering a Honda Pilot Clicking Noise During Braking

Listen for one or more clicking noise from the front suspension while accelerating from a moderate stop (between normal and abrupt), or while braking.