Turbochargers are great for adding power to any gas or diesel-powered engine, but especially for small displacement engines. They were all the rage back in the 1980s when BMW, Mitsubishi, Toyota and Volkswagen all offered turbo options on a variety of engines.

Over the years, turbos have come and gone, but recently, they are making another major comeback as automakers downsize engines for better fuel economy. Adding a turbo allows a small displacement, four-cylinder engine to deliver the “go power” of a V6 with the fuel economy of a four.

For example, Audi’s 2.0L TFSI (Turbo Fuel Straight Injection) engine in the A4 produces 200 hp (147 Kw) and 207 lb.-ft. (280 newton meters) of torque. That’s 100 hp per liter, which is good enough to accelerate from zero to 100 km (62 mph) in 6.3 seconds. The 2016 A4 2.0L delivers even more punch, with 252 hp and 273 lb.-ft. of torque. These same engines are also offered in a variety of VW models.

Every projection today is for continued growth of small displacement turbocharged gasoline engines. When combined with exotic operating strategies such as a “Miller” combustion cycle (which delays the closing of the intake valve on the compression stroke and uses turbo boost to help compress the air/fuel mixture in the cylinder), fuel economy gains of up to 15% or more are possible. Audi offers such a setup on its 2017 A4. The new engine actually has less horsepower but a broader, flatter torque curve.

The small engine, big performance trend is no different among other European nameplates such as BMW and Mercedes-Benz. BMW turbo six-cylinder engines like those in the 330 Series are high-performance, high-efficiency engines. Mercedes prefers superchargers (compressors) for some models and turbos for others. Either way, boost pressure makes any small engine breathe and perform like a much larger naturally aspirated engine.

Turbodiesels are also popular with the European automakers, although there are some questions about what impact the VW emissions-cheating scandal will have on the future availability and sales of diesel-powered cars here.

The Japanese automakers have mostly avoided turbos in recent years, but Korean-made Kia and Hyundai models do offer a couple of turbo options. Asian manufacturers prefer hybrid technology for boosting fuel economy, but this too may change in the years ahead.

The point is there are a lot of turbocharged cars and light trucks on the road today, and there will likely be even more as time goes on. So, there are ample opportunities to perform turbo diagnosis and repair work on a variety of makes and models.

How A Turbo Works

A turbocharger forces more air into an engine to increase volumetric efficiency and power. A turbo uses an exhaust-driven turbine wheel to spin a compressor wheel that blows more air into the intake manifold. Although this creates some backpressure in the exhaust system, it allows the turbo to deliver far more power than it uses. It also improves the engine’s overall thermal efficiency by using waste heat that would otherwise go out the tailpipe.

In that respect, a turbo is more efficient than a supercharger. Superchargers are belt-driven rather than exhaust-driven and can eat up 40 to 50 hp just to power the blower.

Turbochargers have to spool up to speed before they deliver adequate boost pressure. Peak turbo speeds may be 100,000 to more than 250,000 rpm depending on the application, and most don’t deliver much boost below 2,500 rpm. Peak boost pressure on most passenger car applications is limited to about 9 to 11 PSI, but some high-performance applications can go much, much higher.

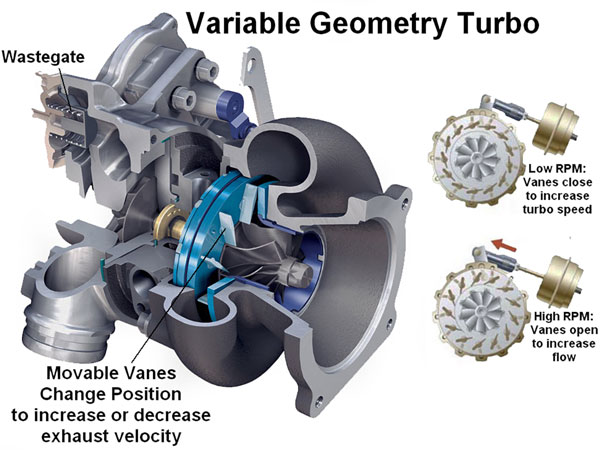

Low-speed throttle response and boost pressure can be improved by using a smaller turbo or one with a “variable nozzle” or “variable vane” design. The variable geometry turbos have movable vanes in the turbine housing that change position to increase exhaust velocity at lower speeds for faster spool up and response.

A “wastegate” valve on the turbo limits boost pressure. A spring-loaded vacuum valve actuates the wastegate, but on most late-model applications boost pressure is also controlled by the engine computer using a solenoid and sensor inputs to monitor engine speed, load, throttle position and manifold boost pressure. The wastegate is essentially a dump valve that opens to vent excess pressure. Over-boosting the engine can lead to detonation, overheating, head gasket failure and engine damage. The wastegate controls the rate at which boost pressure builds and limits peak pressure and torque to protect the engine. The boost strategy on most late-model engines is to develop boost as quickly as possible for more low-speed torque.

A turbo can increase engine power 25% to 50% (or even higher in racing engines). The higher the boost pressure is dialed up, the more power the engine makes. A popular upgrade for many turbodiesels and gas turbos is to reprogram the engine computer with a performance tune that “ups” the boost pressure. A performance tune can add another 50 to 150 hp, but automakers may not honor a powertrain warranty claim if the PCM has been reflashed with a performance tune. The tune leaves permanent tracks in the PCM’s memory, even if it is erased and returned to a stock tune, so proceed with caution if a customer asks for this kind of upgrade.

The Intercooler

Another component that helps the turbo boost power is the intercooler. The compressed air exiting the turbo compressor housing is hot, so it is routed through an air-to-air or air-to-liquid intercooler before it enters the engine. Air-to-air intercoolers are usually mounted in front of the radiator and A/C condenser. Cooler air is denser than hot air and provides more power while reducing the risk of detonation.

Obviously, the intercooler needs to be unobstructed and flow freely to deliver peak performance. Like radiators, intercoolers can become clogged with bugs and road debris.

Turbo Maintenance

Turbos do not require any special maintenance because they are sealed assemblies that are cooled and lubricated by the engine’s oil and cooling systems. However, it is absolutely essential to use a high-quality motor oil that meets OEM specifications (synthetic oils are usually recommended) and that the oil is changed according to the OEM’s recommended service intervals. Pushing the oil beyond the recommended mileage limits is asking for trouble.

Synthetic oils or high-quality synthetic blends that are “turbo approved” are usually the best choice for turbos. Turbos trap a lot of heat inside the turbine housing. The heat conducts down the shaft into the center housing. If the oil flowing through the turbo gets too hot, it will oxidize and burn.

If a cheap “generic” mineral-based motor oil is used in a turbo motor, the oil may not withstand the heat very well. Oxidized oil can form hard carbon deposits on the turbo shaft that’s murder on the bearings.

The oil lines to and from the turbo also need to be clear, free from sludge or obstructions, and the engine has to have adequate oil pressure to keep the turbo lubricated. Any problems with oil pressure, oil supply or oil aeration (air being sucked into the oil pump) may cause turbo lubrication problems. Consequently, if a turbo has died due to a lubrication failure, it’s important to diagnose the underlying cause so the same thing doesn’t happen again when the turbo is rebuilt or replaced.

Some turbo motors (Audi and VW to name two) have a reputation for using oil. The problem, however, usually is not an oil leak in the turbo shaft seals, but rather a piston ring sealing issue. Some of these engines can use a quart or more of oil every 1,000 to 1,500 miles. Audi and VW insist this isn’t a problem as long as oil consumption is less than a quart every 800 miles.

Late-model turbos have a water-cooled center housing. This helps prevent overheating and reduces oil oxidation. Even so, it’s still good advice to let a turbo slow down and cool for a minute after high-speed driving before turning the engine off. Coolant will continue to siphon through the housing after shutdown, and, on some applications, an electric pump is used to keep the coolant flowing until the turbo has cooled sufficiently. If the turbo coolant lines are kinked, obstructed or full of air because of a low coolant level, the shaft bearings may not receive adequate cooling.

When Good Turbos Go Bad

Like any mechanical component, turbos are vulnerable to wear and tear as the miles add up. They are most vulnerable to lubrication-related issues, such as poor-quality oil, not changing the oil often enough, dirty oil, low oil level or low oil pressure. But turbos can also suffer the ill effects of high exhaust temperatures. Heat may cause the turbine housing to crack and leak. Poor air filtration that allows dirt and dust to be ingested past the air filter can erode the compressor wheel over time, causing a gradual loss of turbo efficiency and boost pressure.

Turbos use different types of bearings, including steel and ceramic ball bearings, full floating bronze bearings that ride on an oil film, and rigid bronze bushings. All depend on a constant oil film to minimize friction and wear. If the bearings or bushings become worn, the shaft may wobble as it rotates. This creates harmonic vibrations that can prevent the turbo from achieving its normal operating speed and boost pressure. A buildup of deposits on the shaft or bearings will create drag that can also prevent the turbo from spinning freely. If the shaft binds up, the turbo may not spin at all.

A turbo may also fail to deliver normal boost pressure if there are leaks in the intake plumbing. Noise such as whistles or hisses would indicate air leaks in the turbo housing, connections or hoses.

Turbo Symptoms

The classic symptoms of turbo trouble include:

• Loss of power. Power and torque will be noticeably reduced because the turbo isn’t spinning as fast as it should and is not developing normal boost pressure. This can be caused by worn or damaged shaft bearings, airflow obstructions in the intake or exhaust systems, air leaks in the turbo discharge and intercooler plumbing, dirt or debris clogging the intercooler, a leaky wastegate, or defective wastegate electronic controls.

Low boost pressure can also be caused by erosion wear on the compressor or turbine wheels. The tolerances inside the housings are very close, so any increase in the clearances can reduce boost.

• Excessive oil consumption and/or blue smoke in the exhaust. If you discover oil inside the compressor housing, the seal on the compressor side of the center housing is leaking.

• Reduced throttle response in an application with a variable nozzle or variable vane turbo. Carbon can build up on the vanes, preventing them from changing position. The vanes may become stuck in the low rpm or high rpm position. Using an aerosol cleaner designed for this purpose (or for cleaning EGR valves) can often loosen the carbon deposits inside the turbine housing.

• Sluggish throttle response and/or loss of power due to carbon deposit buildup on the turbine wheel. Deposits add mass and inertia, which makes it harder for the turbo to spool up quickly. Use an aerosol cleaner to loosen and remove the deposits.

• Sluggish acceleration and/or loss of power due to a damaged or eroded compressor wheel or turbine wheel. If the blades are worn, broken, bent, cracked or damaged, the turbo may not deliver normal boost pressure. Replace the damaged parts or the turbo.

• A buzzing noise that sounds like a dentist’s drill. It’s a high-pitched whine from the turbo caused by excessive play in the shaft bearings and/or contact between the turbo wheel and housing.

• Intake and exhaust manifold gasket leaks caused by excessive boost pressure, heat or corrosion. Intake plumbing leaks typically produce whistling noises when the engine is under load. Exhaust leaks will produce a familiar growl, hiss or rumble.

Boost Leak Checks

Leaky hoses, hose connections or leaks in the intercooler can all reduce the amount of boost pressure the engine receives when the turbo kicks in. You can check for boost pressure leaks by disconnecting the outlet tube at the turbo and plugging it with an adapter that has an air fitting. The tube that connects to the throttle body also needs to be disconnected and plugged to seal the other end of the plumbing. You can then pressurize the intake system with a regulated air supply at 5 PSI, then again at a pressure equal to the peak boost pressure of the turbo (usually 12 to 15 PSI for most stock turbos).

If the intake plumbing fails to hold pressure, there is an air leak somewhere. Listen for leaks (hissing sounds) and spray soapy water on suspected leak points to see if bubbles appear. Pay close attention to the intercooler inlet and outlet fittings because the gaskets on some intercooler outlets often leak. Also check the wastegate.

Repair Options

If a turbo has damaged shaft bearings, the center “cartridge” can usually be replaced separately from the compressor and turbine housings. A reman cartridge includes the center housing, shaft, bearings or bushings, seals, turbine wheel and compressor wheel, that are all preassembled and ready to install. Replacing a cartridge is less expensive than replacing the entire turbo, but it also requires more disassembly and assembly labor.

If the turbine or compressor housing is cracked, worn or damaged, that too may have to be replaced — or you could simply replace the entire turbo assembly with a new or remanufactured unit. Most new and reman turbos come with new heat shields (which are often corroded and in poor condition on high-mileage turbos), a new wastegate (if it is part of the turbo) and a warranty.

If a new wastegate is not included with a replacement turbo, it should also be changed on a high-mileage vehicle. The same applies for the boost controller on variable-nozzle and variable-vane turbos. Additional parts you may also need include hoses, clamps, motor oil and a filter.

Some of your customers may be interested in upgrading their stock turbo to a more efficient or larger aftermarket performance turbo for increased performance. Bolt-in replacement performance turbos are available for various applications. Upgrading the turbo can boost power significantly, although typically at higher engine speeds. Low-speed torque and throttle response may not be as good as with a stock turbo.

Swapping a performance turbo for a stock turbo will require some additional modifications. A larger or more efficient intercooler is usually recommended. Some of the inlet and outlet plumbing may also have to be changed. The PCM will also have to reprogrammed with new boost control, fuel and ignition calibrations. This will require a “tuner” scan tool to install the new instructions or some type of tuner software for a laptop (and the know-how to use it!).

The easiest (and safest) approach for installing a performance tune on a turbo motor is to go with a “canned” tune from a tuner scan tool supplier. These are available for stock turbos as well as modified turbos. The supplier can create a revised boost control, fuel and ignition map based on the information you provide (which includes the basic vehicle application information along with any other engine, fuel, ignition or exhaust modifications that have been made). Or, you can take the vehicle to a performance shop that specializes in dyno tuning and let them do the reprogramming.

Adapted from an article in Import Car.