uilding an engine or resurfacing brake drums or other components, deglazing is also a vital function that is performed well by the properly selected ball-style hone.

“We’ll use a Flex Hone ball-style hone for deglazing a cylinder,” says Don Bolland, president of Bolland Machine (Beaver Falls, PA). “More frequently, we’ll use it on a diesel engine to clean the counterbores after we pull the old cylinder liner out."

"That is very important in order for the O-rings to seat properly when you install the new cylinder liners. Or, if we are simply re-ringing an engine, then we’ll use the ball-style hone just to de-glaze the cylinders.”

Bolland Machine, which specializes in a wide range of engine components and assemblies, specializes in the rebuilding of gasoline and diesel engines ranging from small, engines up to very large Waukesha industrial engines used for pumping natural gas through pipelines.

Bolland Machine is also capable of restoring antique engines as well as working on racing engines, and has a division called Bol-Tech Motorsports, that participates in big-block dirt modified racing.

“We use the BRM Flex Hone ball-style hone in some of our performance engine work,” Bolland says. We use a CK10 cylinder hone and have used the Flex Hone to obtain a different finish for different performance applications. It is a very practical way to achieve a surface that is optimum for seating new rings.”

Taking the edge off

Taking the edge off

More frequently Bolland Machine uses the ball-style hone on 5- to 12-inch engines in lower counterbores, where it is important to create a surface with an entry taper that allows an o-ring to smoothly slide into that bore. The edge-blending capability of the ball-style hone removes the sharp rim that could cut the liner O-ring.

For bores 12-inch and larger, BRM has made special ball-style hones for Bolland Machine. “We’ve actually found a niche where they have custom-made hones of up to 36 inches that we use for special applications such as large vacuum pumps and big compressor cylinders.” Bolland says.

“I don’t know of anybody else in the brush hone industry who can do that.”

Tomadur also uses a Flex Hone ball-style hone to de-burr the chamfer on the bottom of piston cylinder bore. “On many engines there is a sharp edge at bottom of the cylinder bore after machining,” Baloga explains.

"You have the potential for piston skirt scuffing because the piston skit goes out past the bottom of the cylinder walls on some engines. So, we use a Flex Hone ball-style hone to create a smooth radius at the bottom of the cylinder bore. It takes only about five seconds to do, and it can prevent a lot of problems.”

In addition to combustion cylinder work, Tomadur also uses a Flex Hone tool to create a blended radius on hydraulic valve lifter bores, thereby avoiding scuffing problems on valve lifters.

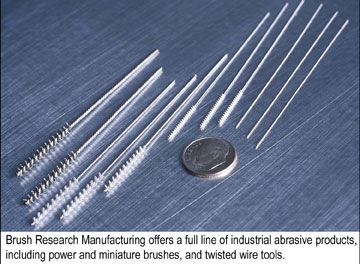

Established in 1958, Brush Research Manufacturing has been solving difficult finishing problems with brushing technology in the sophisticated environments of nuclear energy, aerospace and computer technology as well as industrial applications.

For more information, contact Brush Research Manufacturing, Brush Research Mfg. Co., Inc., 4642 East Floral Drive, Los Angeles, CA 90022; Phone: (323) 261-2193; Fax: (323) 268-6587; email: [email protected] or visit the web site: www.brushresearch.com.