Welcome back to another “easy to use tip” from a concerned instructor/master tech. The smallest, and sometimes the least expected, issues cause techs the most trouble when assembling items on vehicles. Taking things apart is generally never an issue, but taking them apart without destroying them can be a big issue. For example, putting small fasteners back in more difficult or awkward places is a major issue.

This month’s tip pertains to the installation of cap screws/bolts into these type of places. There are plenty of tricks that several old school techs have developed that work well. I am going to take this opportunity to tell you about one I developed through my suffering and agony trying some awkward bolt installations.

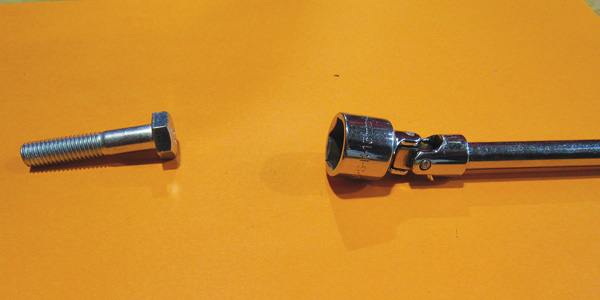

1. Awkward installs generally require the use of universal joints and/or universal sockets. Grab the fastener and your choice of socket.

2. Place your bolt into the socket. Using Teflon pipe tape, wrap the pipe tape around the outside of the socket about 1/4” from the edge. Continue to wrap the tape a couple of times so the tape seals to itself. Then, continue wrapping the tape toward the base of the bolt head three or four times. The bolt will stay in the socket upside down, right side up, sideways, or any other direction you can think of.

3. Install your fastener applying the proper torque and the tape automatically will stretch off the fastener. You can also use Teflon tape for securing fasteners with Phillips, Posi-Drive, Torx or standard slotted heads. Hope you enjoyed this educational tip and are able to benefit from it.