If an engineer could design a belt system that would never slip it would be a miracle. This perfect belt system would last a long time because without slipping, there would be very little wear. But, it is not that simple. Too much tension would increase the loads on the engine and the strain on a belt is not constant. It is a balancing act between drag, slippage and belt wear.

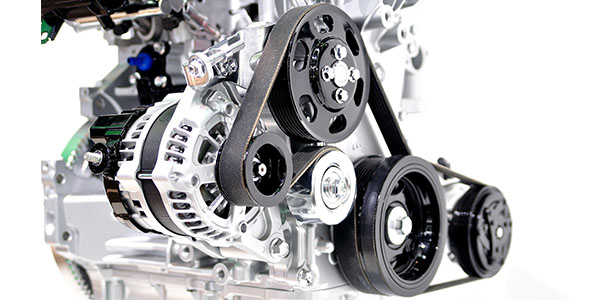

The engineers manage slippage by controlling how much of the belt makes contact with a pulley. How much force is required to turn a component will determine the amount of belt contact. For example, an A/C compressor pulley might have more belt contact, while a power steering pulley will have less.

As an accessory belt drive system ages, many things can change. The tensioner, belt and even the alignment of the pulleys can change. These changes can reduce the amount of adhesion the belt can apply to the pulleys. As the amount of slippage increases, the rate of wear on the belt grows exponentially.

The Tension

Watch the belt while the engine is running. If you see a lot of movement or flutter in the belt, the tensioner is probably weak or sticking and should be replaced. Many tensioners also have an indicator mark that shows its range of travel. If the mark is not within the normal limits, the tensioner is weak or sticking, or the belt is not the correct length for the application.

An automatic tensioner has a coil spring inside that applies just the right amount of force against the belt to keep it tight. The tensioner also provides a little “give” so it can absorb and cushion shock loads on the belt that occur when the A/C compressor clutch cycles on and off. What’s more, the tensioner automatically compensates for wear and keeps the belt under constant tension. But, nothing lasts forever — not belts and not automatic tensioners. Most engineers design the tensioner to last the life of the belt.

Belt tension is critical. Too little tension may allow the belt to slip and squeal. Slippage also causes the belt to run hot and age prematurely. And if the belt is loose, it may come off its pulleys. Too much tension on a belt may overload it in addition to the shaft bearings on the water pump, alternator, power steering pump and air conditioning compressor, possibly leading to premature failures in these components.

Decoupling

Another item that can affect a belt’s performance is the pulley. Many late-model vehicles do not use a solid alternator pulley. Instead, they have an Overrunning Alternator Pulley (OAP) or an Overrunning Alternator Decoupler Pulley (OAD). An OAP has a one-way clutch mechanism inside the hub that allows the belt to turn the alternator in one direction but allows the alternator to freewheel and spin at its own speed when the engine suddenly decelerates.

If an alternator with an OAP or OAD pulley is being replaced, and the replacement unit does not come with a pulley already installed, the original pulley can be removed from the old alternator and installed on the new unit — provided it is in good condition. However, on high-mileage vehicles, replacing the original OAP or OAD pulley with a new one is recommended to assure trouble-free operation.

Going 100,000 miles or more is almost a miracle for some belts. Getting the next belt to go the 100,000 miles with out premature failure is up to a technician to make sure the belt does not succumb slipping and excessive wear.

Article courtesy Underhood Service.