When faced with an illuminated charge light diagnosis on most late-model vehicles, do not automatically assume the problem is inside the alternator and potentially unserviceable. The problem could be the pulley and belt drive system. Neglecting to test and diagnose the pulley can lead to unnecessary replacement.

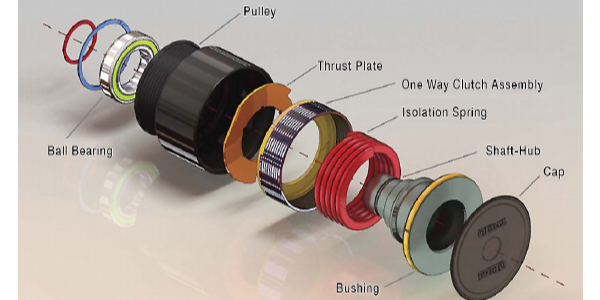

Almost every late-model car or truck is equipped with an overrunning alternator pulley (OAP) or an overrunning alternator decoupler (OAD). An OAP is a one-way clutch like a socket wrench that turns in one direction and locks when turned the other direction. An OAD operates in the same manner but has a special clutch and spring that absorbs vibration to smooth out the vibrations in the drive belt system. Regardless of the type, the pulley should be checked before condemning and removing the alternator.

These new pulleys allow the alternator to “free-wheel” or “overrun” when the belt suddenly slows down. This prevents the belt from slipping and reduces vibration. Best of all, the system needs less tension and you can even use a narrower belt. This can result in a 1.5% to 2% fuel economy improvement. However, these pulleys have a limited lifespan due to how they operate internally.

OADs and OAPs behave the same, except the OAD will have a “spring feel” because of the internal spring. Testing can be performed on the vehicle with the belt attached.

Inspection Procedure

- Raise engine speed to 2,000-2,500 rpm in Park (auto trans) or Neutral (manual trans) and then shut off the engine. Listen for any noises from the OAD after the engine is shut off. A worn-out bearing will generate a “buzz” noise during this test. If the OAD is noisy during this test, replace it.

- Remove the cap, and with the proper tool inserted into the front of the OAP, rotate the alternator’s shaft in both directions. In the overrun direction, it should feel smooth and in the drive direction, it should have a spring feel.

- If the pulley is locked up, replace it.

- If the OAD has no spring feel in the drive direction, replace it.

- If the OAD requires more than 9-13 in./lbs. (1-1.5 Nm) of torque to turn in the overrun direction, replace the OAD.

- If the OAD is not smooth in the overrun direction, replace it.

Article courtesy Underhood Service.