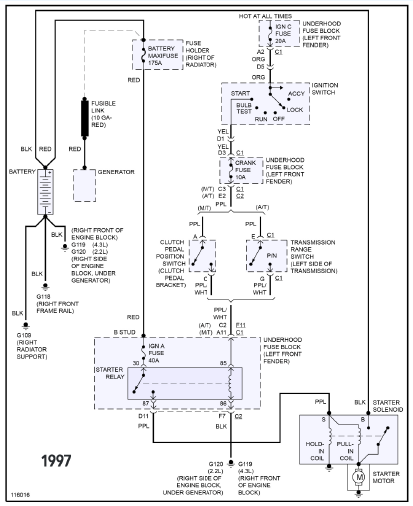

To understand keyless entry, remote starting and security, you first have to understand the evolution of the circuit that starts the vehicle. For almost 50 years, the circuit going from the ignition key to the starter did not change.

When the key was inserted into the ignition, the shape of the key and the pins of the tumbler hopefully aligned so that the key could rotate. The key would turn a rotary switch with contacts for the electrical power for the coil, lights and other components. If the driver bumped the key forward, it would send power to the solenoid to activate the starter.

This system remained the same for decades. About the only thing that changed was the addition of relays into the circuit. These relays could be used as a safety mechanism to disable the starter if the clutch was not pushed in or the vehicle was not in park.

With this type of keyed ignition switch system, it was effortless to defeat the security with a slide hammer and screwdriver. Also, due to growing electrical loads, running a lot of current through one switch was not a good idea.

In the late 1980s, an extra layer cof security was added by many manufacturers. GM started to use a chip that was nothing more than a resistor in the ignition key. The key had one of 15 resistive values that were measured by two contacts in the ignition key tumbler. If the resistive value matched the pre-programmed value, the starter relay could be energized, and power would make it to the starter’s solenoid.

Most manufacturers took the system one step further by embedding radio frequency identification (RFID) chips into the keys. The keys would be energized to transmit a security code to a module through a ring around the ignition tumbler.

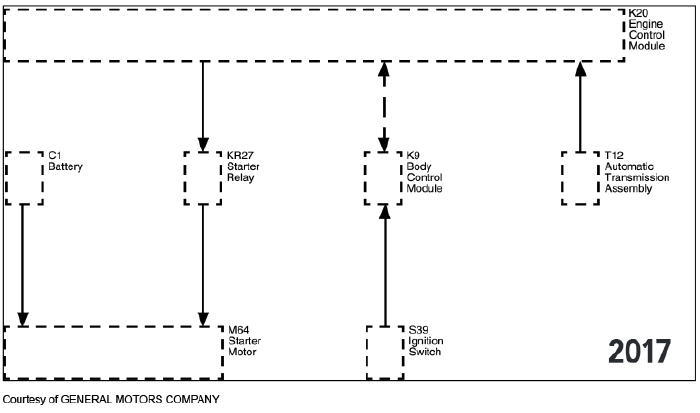

In the early 2000s, the ignition system evolved further. Most of the first system modules were stand-alone systems with very little communication with engine and body control modules. This changed as more networks and modules made their way onto vehicles.

When a vehicle starts today, it is a symphony of communication between modules, and the energizing of the starter is only one of many events. If you compare a modern ignition switch or a keyless start button to an old ignition switch tumbler, you will see a change in the architecture. Instead of the switch having a direct connection to the starter, it connects to a module and is just one of many inputs that could be communicated through many modules. It is now a module that controls a relay that engages the starter.

Part of the equation is still the key. Most vehicles still require a physical key to start the vehicle and turn the tumbler on the steering column or dashboard. Many physical keys have become very sophisticated, so they cannot be cut by a locksmith. Even if the car does not require an ignition key, it will still have a physical key to unlock the doors if the battery is dead. But, if the key can’t turn the tumbler, it will not start.

The other part of the key is the radio security features. In the past, the RFID chip sealed in a glass vial in the body of the key had to match the ID programmed into the vehicle. With these systems, the chip has to be very close to the antenna ring because the coils provide power to the chip to transmit. When diagnosing these types of systems, it is essential to inspect the key as well as the antenna ring.

Just when you get comfortable with one technology, they make a change. With proximity key systems, the security ID and codes are now integrated into the electronics of the key fob because it has to transmit yards instead of an inch.

Some vehicles may have as many as six antennas positioned in and around the vehicle at strategic locations like the trunk and driver’s door. Some systems may use just one antenna. This is why it is critical to use service information when solving a security or no-start problem.

What is being transmitted?

Even if it is a basic keyless entry system, the signal follows a similar protocol to a proximity key system. When the button is pressed to unlock the vehicle, it transmits a message in code. This message, sent between 315 and 433 Hz, contains information identifying the key fob, command and unique rolling code.

The rolling code prevents thieves from listening to the signal and repeating it to access the vehicle. The rolling code changes every time a button is pressed. When a key is coded to the vehicle the rolling code is set. It could be a four-digit number that increases by a preset value. This value is not transmitted. Rolling codes are difficult to crack and require very sophisticated tools. When you program a key to a vehicle, you are setting the rolling code.

Some late-model vehicles will transmit a challenge signal to the key fob as extra security before starting the passive entry process. If the fob does not transmit the correct signal, the vehicle will remain locked or not be able to start.

Scanning

Before you replace a battery or starter, pull out your scan tool. With a scan tool, you can confirm the operation of the security system and if there are any communication issues with the modules on the vehicle. With right scan tool, you can see the operation of the antennas, fobs and even how many keys are programmed to the vehicle.

Key Replacement

Three situations might require key programming capabilities at your shop. First, being able to diagnose and program keys can be a tool as part of some no-start diagnostics. Second, you may run into a situation where a key or fob needs to be reprogrammed to the vehicle if a module was replaced. Third, a customer might want an extra key, or all the original keys were lost.

You might think that key programming is a job for a locksmith or specialist, but the market is changing. Brick and mortar locksmith and dealership parts departments can cut key blanks, but it is up to you to make them work with the vehicle. In the case of some proximity keys, there is no key to cut – it is all up to you.

Article courtesy Underhood Service magazine.