This article is courtesy ENGINE BUILDER.

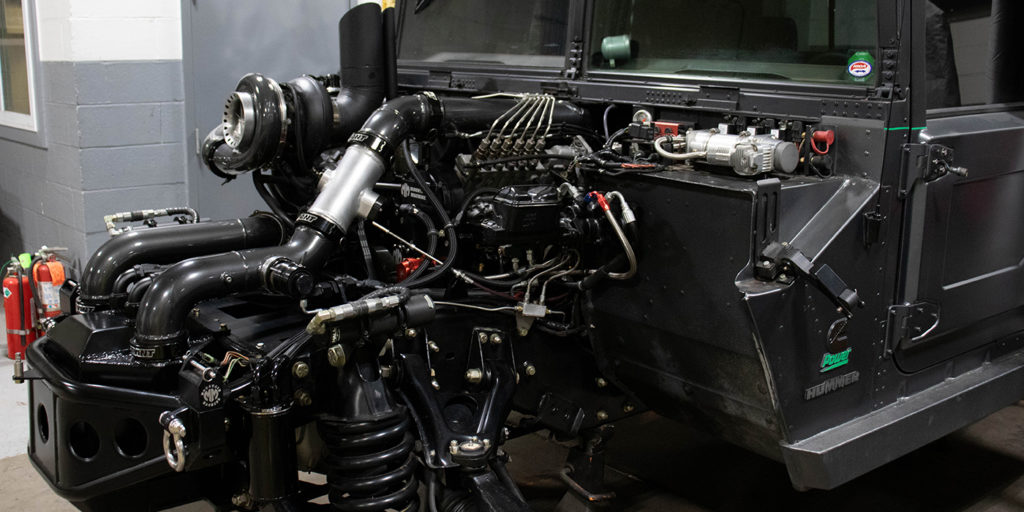

Every now and then, it’s fun to build something truly badass. Something that goes against the grain. Something you know the purists won’t like. Something that might not make total sense, because sometimes, you just have to build what makes you happy. That’s exactly what Steve Ortner recently did when he outfitted his H1 Hummer with a turbocharged 6.7L Cummins engine.

Steve Ortner owns Mountain Machine, a CNC machine shop located in Belleville, MI. Ortner began his career in the military, but eventually found his calling in CNC machining. His industry knowledge and skills were honed working for Roush and Kalitta Motorsports, then, Ortner founded Mountain Machine in 1999. He started with two machines operating out of his garage. Two decades later, Mountain Machine now operates in a 32,000-sq.-ft. manufacturing and development facility.

“I’m a machinist,” Ortner says. “I own a machine shop and it’s what I’ve done my whole life. That’s the only thing that I’ve ever been good at. I was in the Air Force for four years, and then I got out and worked for Connie Kalitta for three years. I left there and worked for Jack Roush for eight years. Then, I bought a Bridgeport with my tax return and I put it in my little 16’x16’ garage. Now, I’ve got 17 guys and 32,000 square feet, 15 CNC machines and all kinds of other stuff – it’s been really good.”

While the machining business keeps humming along, Steve is a guy who also really likes to have fun. One of his long-time dreams has always been to own an H1 Hummer.

“I always wanted an H1 Hummer ever since seeing the first one,” Ortner says. “Probably five or six years ago, I bought one. Back then, I knew nothing about diesel motors, but I decided I was going to put a Cummins in it. I bought the truck and then I bought the motor and then I started working on it and realized I wanted to put compounds on it.

“I started learning and growing within the diesel world. I met some people in the industry and then I started going to events like the Ultimate Callout Challenge and helping some of those guys out. I got hooked on it.

“I got my first truck done. It took me two years to do it and it had a small set of compounds on it and I was totally hooked. I ended up blowing that engine up and putting a mild one in it to get it rolling again, but I knew I had to do something bigger with it. It took me three more years and I’ve been gathering parts for this engine, and I finally got it all together. We put it together this last fall.”

Steve and a few of his guys took the Cummins swapped Hummer to Moab recently, and as expected, the truck is “just absolutely freaking ridiculous” as Steve puts it. “I wasn’t looking to build something that is a rock climber truck or even a street truck,” he says. “I wanted to haul ass through the dunes and climb hills with a vengeance.”

Mountain Machine now has four full-time guys that do nothing but help Steve work on those kinds of trucks and billet parts for the builds. While the shop has done some truck builds for other customers, Steve says nobody wants to build a truck like that Hummer.

“Everybody wants to still have the modern luxuries,” he says. “That’s cool, but it’s boring. I want something that’s undeniably nuts. Nobody wants to pay me to do that, so I’m going to do it for myself. People in the Hummer world kind of frown on what I do to a degree because a lot of those dudes are purists.”

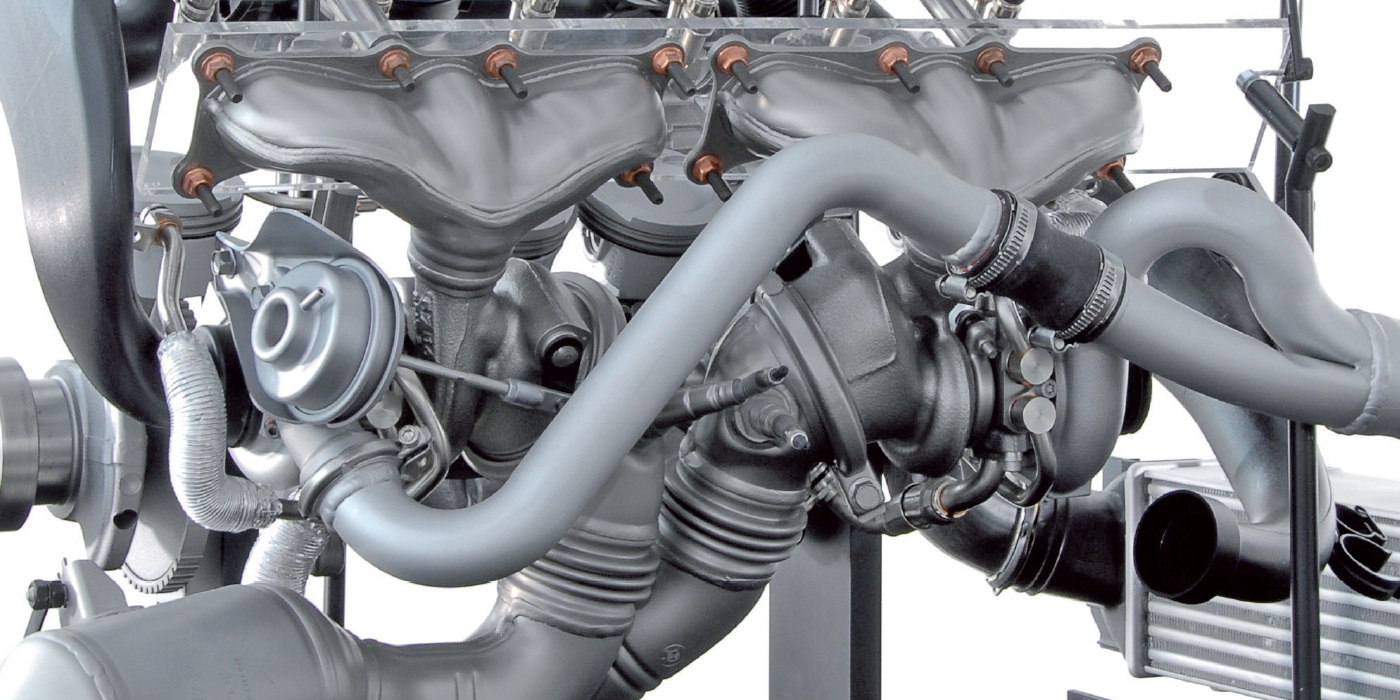

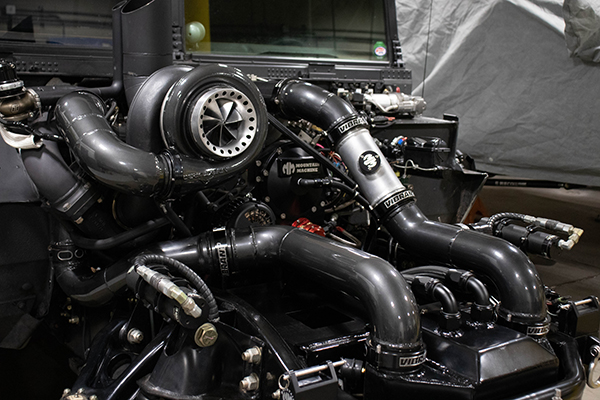

Purist or not, it’s hard not to appreciate what Steve and his team built. His latest 6.7L Cummins engine started with a Hamilton 6.7L wet race block. It’s got Diamond billet, short projection pistons in it with Wagler billet, 1-inch longer rods. It’s got a stock Cummins crankshaft, and it’s got a custom billet girdle in it. It’s got a Hamilton cam, Hamilton lifters and Hamilton pushrods. It also has a Cummins cylinder head that Mountain Machine cut the shelf off of and put big valves in it and big block Chevy springs.

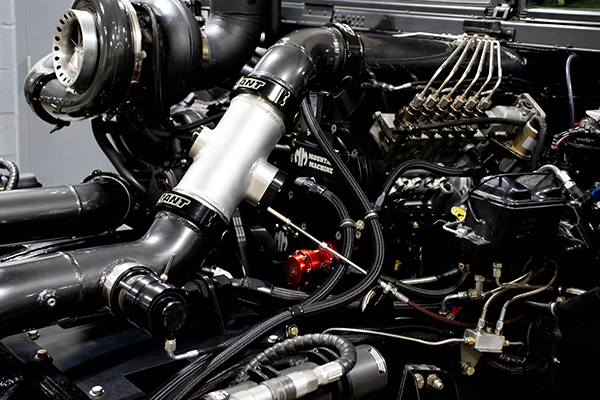

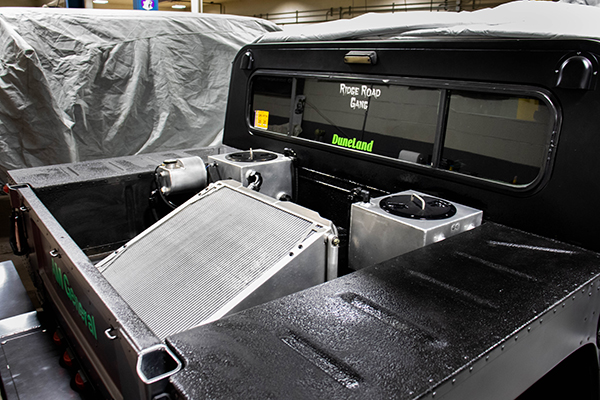

“We machined our own billet runner intake for that thing and drilled and tapped it for the water-meth,” Ortner says. “We put the cooling pack in the bed of the truck. We did that because we built our own billet gear case. That’s how this deal got started because I bought a block and I wanted to put a P-pump on it. I’ve always been a P-pump guy. I love the way they sound. I love everything about them. This project started by building a billet gear case so we could put a P-pump on a 6.7L.”

Mountain Machine moved all that stuff in the back so you could see all the billet stuff in the front – the billet gear case, the billet runner intake, etc. The Cummins engine also features a Steed Speed manifold with a T6 outlet and an S400 manifold charger from Apex, which is an 86/88 and it’s got a 110/114 blade in it. It has a billet center section that Mountain Machine made and a billet backing plate with triple ball-bearings in it.

“The cylinder head was quite an ordeal,” Steve admits. “We ended up making our own multi-layer copper head gasket because the water on a 6.7L head and the water on a 12-valve, they don’t line up. We modified the cylinder head mainly, trying to keep from messing with the block in case I want to put a common rail head on there, which I might end up doing. For now, the head is a modified and ported stock head.”

Mountain Machine also got some help on the build from Vibrant Performance, which supplied the plumbing, and from Farrell Diesel Service, which supplied the injection pump.

“It’s primarily a sand dune truck,” he says. “We put a big, huge radiator in the bed of the truck and it’s back there with the water to air intercooler tank and that pump and the water/meth pump, the heat exchanger and all of that – it’s all in the bed of the truck. We have a big Ron Davis radiator with the biggest small fan you can buy. The truck actually stays really pretty cool. I might drive it on the street a little, but only to a car show or something. It’s too angry to try to go too far in it.

“I wanted to put together something that was super strong that I could pour some good boost to and sounds amazing and runs like a scalded dog, but is still sturdy and can drive for a little while. You can take it out on the dunes and cruise around and rip up some hills, and then cruise around down by the beach and not have to worry about the thing overheating. I don’t want to do a quick shot and shut it off.”

With the water-meth set up and a short-duration Seth Farrell 14mm fuel pump, the engine can make around 1,500 horsepower. It’s only got around 28-degrees of timing, so it starts really easily, according to Ortner.

All we know is we’re glad people like Steve and his team exist to create builds like this! Cummins swap approved!

Diesel of the Week is sponsored by AMSOIL.