Automotive technicians love to read about “real-world” challenges – oddball occurrences with a component that cause a fellow technician to launch his 3/8˝ ratchet across the shop and utter enough swear words to make Andrew Dice Clay cringe.

The process of finding and diagnosing these challenges can often shed light on a situation that no amount of product knowledge can match. Learning about an uncommon car repair horror story can be helpful not only as a good read but as something else to file in the memory bank for possible use at a later time.

In this particular case, I dealt with a shrinking wheel speed sensor air gap.

The vehicle in question came into the shop with the concern that the ABS and brake lights were illuminated on the dashboard. After verifying the concern, I noticed nothing strange during a few mile test drive. I pulled the car in to begin my diagnostics.

The scan tool DTC retrieval showed a code for “LF wheel speed sensor signal lost,” so I proceeded to drive the vehicle with the scan tool hooked up and observed normal operation of all the speed sensors except the LF sensor. It displayed 0 mph at all times.

Typical, right? Most techs have seen the exact same thing. I then proceeded to ohm-test the sensor with my multimeter and received an open circuit display, indicating the sensor was faulty.

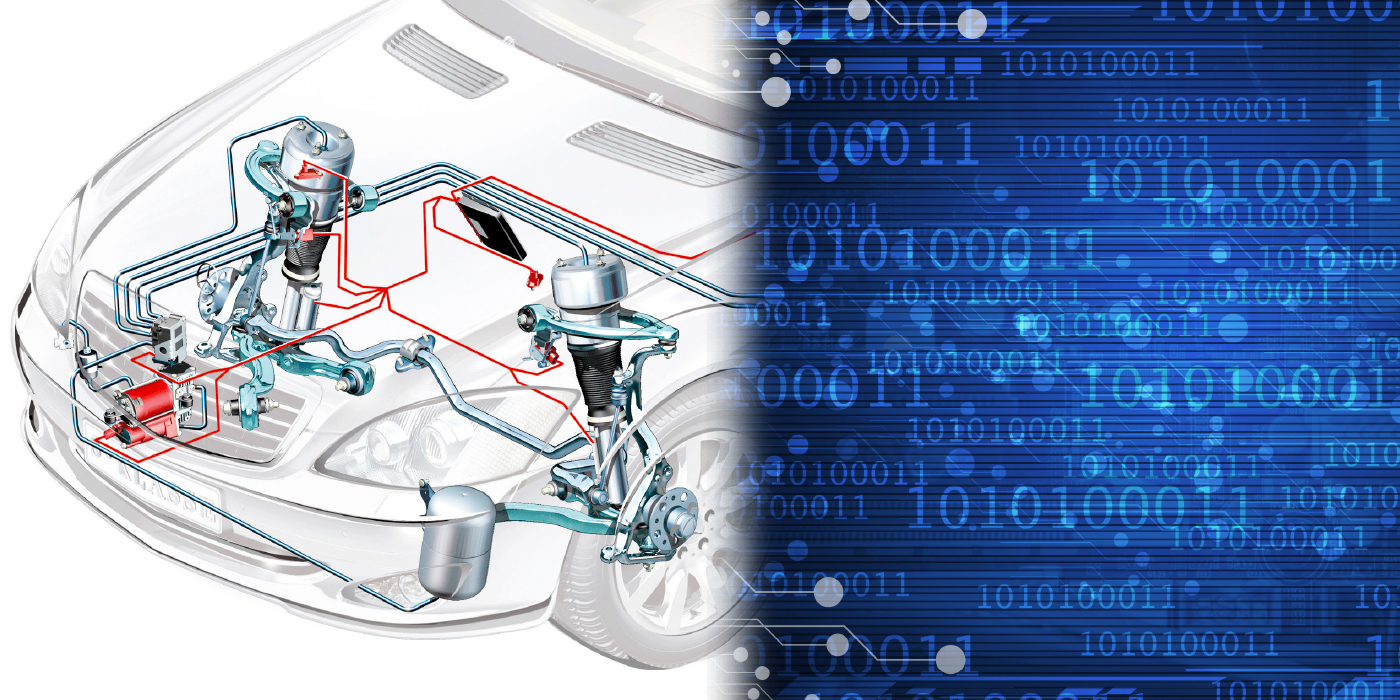

The service advisor sold the job and I started to replace the sensor. Upon removal, I noticed that the end of the sensor that actually “measures” the wheel speed was chewed up – it looked like it had been rubbing against something. I inspected the tone wheel but saw no obvious damage or indication that it was the culprit of murdering the wheel speed sensor. There was no play in the axle assembly causing the axle to jump up and down or wobble, and no excessive play in the hub assembly. In fact, there were no obvious signs anywhere of what caused this to occur.

I installed the new sensor and verified that the air gap was correct, and it was not rubbing on the tone wheel. I chalked up the damage to the sensor as some type of road debris getting lodged in between the sensor and the tone wheel. I cleared the DTCs and test-drove the vehicle around town for a few miles. The ABS and brake lights stayed off and the ABS and wheel speed signals worked normally.

That should have been the end of it, but, as you probably suspect, it wasn’t.

Fast forward a couple days and the same vehicle returned with the same concern. The ABS and brake lights were on again, the same DTC for LF wheel speed sensor signal lost was showing up and the same chewed up sensor was found. And, I still had no idea of the cause. I could rotate the wheel and see that the new sensor was not contacting the tone wheel. All previously checked components seemed fine. So, what kept eating the sensor?

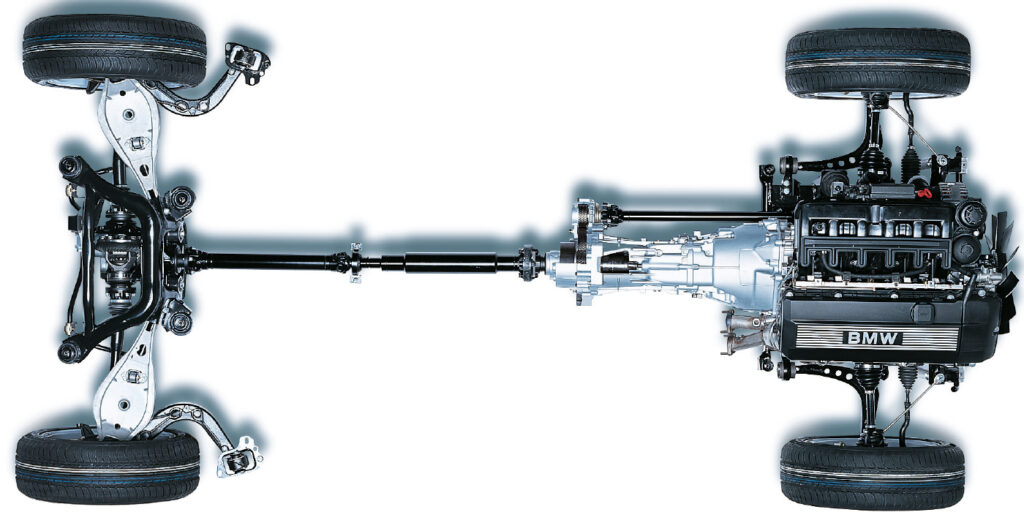

With the help of an assistant, I decided to watch the axle while driving the vehicle as it was raised off the ground on a rack. At 35 mph everything seemed fine – the axle was rotating smoothly and not contacting the sensor. As we brought the speed up gradually, at around 50 mph, I started to hear something rubbing. Upon close inspection, I could not believe what became evident.

The tone wheel had separated at one place from the axle and, due to centrifugal force, started to lift off the axle like a flap and move right into the wheel speed sensor, destroying it in the process. As the speed dropped, the section of tone wheel settled back down again and no longer contacted the sensor. A good lesson learned.

This article courtesy of Brake & Front End.