One thing that all passenger cars and trucks have in common is the braking system. Electric and hybrid vehicles have brake pads like their conventional cousins, but with a twist. In standard friction brake systems, the energy created from applying the brakes is dissipated into the air as heat. In regenerative brake systems, this energy is sent to the batteries to be used later. The connection between the tires and the battery packs is linked via the traction motors that turn into generators. The alternator is an electric motor mounted between the engine and transmission or inside the transmission in a hybrid vehicle.

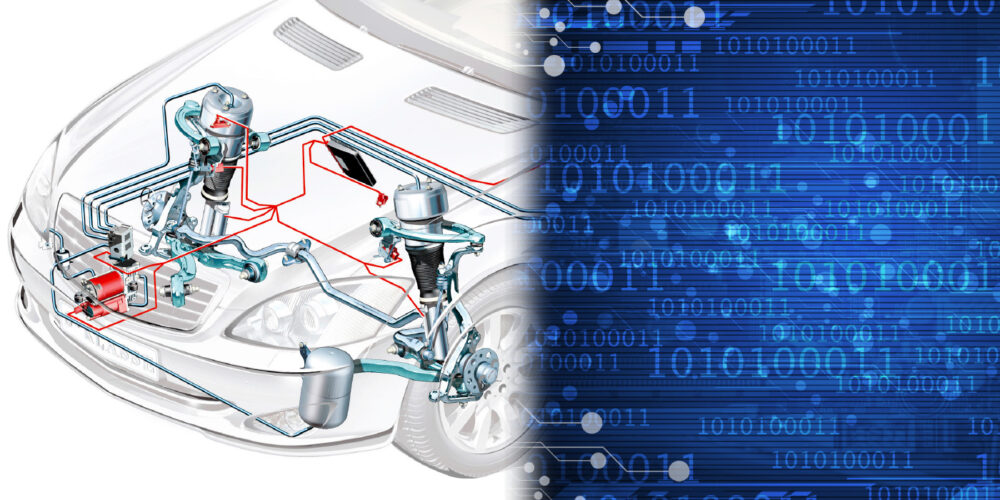

Instead of immediately applying hydraulic pressure to conventional brakes, regen brake pressure is calculated by ABS modules to produce the correct pedal feel and stopping power. The modules that control a hybrid or EV brake by wire system via the traction motor inside the transmission are used to recharge the battery as the vehicle slows down. The more regenerative braking means there’s more electrical charge generated for the battery. The drag created by the generator is used to slow down the vehicle. The hydraulic brakes take over for the final few mph to bring the car to a stop on some hybrids and EVs. However, the balance between regen and standard braking is a hotly debated topic for the electric crowd.

Tesla has been using regen braking from the beginning and has continued developing the system to the point where some drivers can drive with one pedal (no brake pedal necessary). Tesla uses advanced algorithms in the motor controller to complete control of the motor torque for both driving and regenerative braking. Torque (or power) is applied depending on the position of the throttle pedal. The torque command can be used to accelerate or decelerate and recharge. So when the driver lifts off the throttle, the energy is returned to the battery, thus creating regen.

These days, it’s common to see a hybrid with 70,000 or 100,000 miles and still have the original brake pads! With regenerative braking creating the majority of braking force, brake pads wear at a much slower rate. However, the more significant issue is containing any corrosion between the brake pads and baking plate, which is why a high-quality pad with anti-corrosive material is so important.

The hydraulic brakes aren’t applied on early Prius models until the speed is less than 7 mph or the driver makes a sudden stop. Most of the time, the regen system is in use, and the pads won’t be up to operating temperature.

Since it’s impossible to perform a conventional break-in/bedding procedure, be sure the pad materials can perform right out of the box.

As most drivers are used to conventional braking, it may take time for new drivers of hybrid and electric vehicles to adapt to the feel of regen brakes. Still, most people adapt quickly and prefer the motor braking aspect vs. the hydraulic clamping force used in a traditional system. Everyone will drive a hybrid or electric vehicle someday, and regen braking will be as normal as standard friction braking.

Regenerative Braking In Action

The 2020 Ford Explorer Hybrid is the first hybrid version of the Explorer that Ford has made. Ford describes it as “a no-compromise hybrid SUV designed to offer both performance and capability in one fuel-efficient package.”

In 2000, the 2001 Toyota Prius started rolling into U.S. Toyota dealerships, without a lot of fanfare. Looking back, it was the beginning of a new era. The 2001 Prius was the world’s first production hybrid-electric car, and the Prius has become synonymous with hybrid technology. In May 2020, Toyota marked the 20th anniversary of the Prius by offering 2,020 Prius 2020 Editions for the 2021 model year.

Just as the Prius is synonymous with hybrid technology, Tesla has become synonymous with EV technology. While Tesla has been employing regen braking from the get-go, owners of some 2021 models have been reporting that the automaker has removed a feature that allowed drivers to choose between one of two regen-braking “strength” settings. Pictured above is the Model Y, Tesla’s recently launched electric crossover.

This article appears courtesy of Counterman.