Imagine a car without sway bars. The car would experience body roll around corners, but off road and in a straight line, the tires would maintain better contact with rougher roads at lower speed for better traction. However, at higher speeds, the body movement around corners would negate this effect. If you increased the spring rate, it would reduce body roll but would impact ride comfort.

Now, imagine a car with over-sized sway bars and lower spring rates. The car would go great around corners with very little body movement. But, during braking, the rear-to-front weight transfer would cause nosedive and squat, making it painful to drive over rough or uneven pavement. New technology is allowing cars and trucks to have the best comfort, handling and off-road capabilities for trucks.

In 2001, BMW introduced active anti-roll bars on the 7-Series. The bars actively change stiffness to control lateral weight transfer and body roll. These sway bars have an adjustable torsion bar inside a housing located in the center of the bar. The torsion bar is controlled by hydraulic pressure using a hydraulic servomechanism. The system can not only adjust the bar, it can also completely disconnect the bar. Active sway bars allow the bar to disconnect to allow for more wheel travel over rough surfaces.

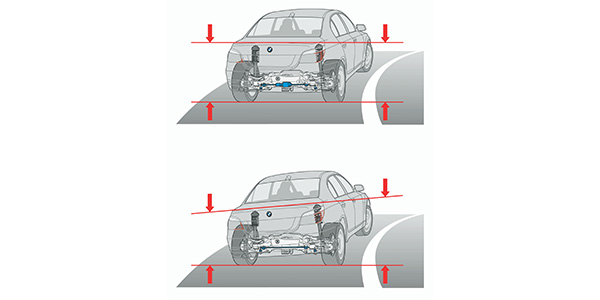

The active anti-roll bar system on these vehicles works in conjunction with the air springs and active dampening system. These components can control the suspension so there are no compromises between spring rates, dampener settings and roll bar diameter. When the vehicle is traveling in a straight line, the bar can be disconnected so each wheel can act independently to absorb bumps. When a corner is reached and steering input is detected, the bar can be engaged to stiffen up the suspension.

Toyota started implementing a similar system on some GS, LS and RX platforms in 2006. The Toyota system is different because it uses electric motors instead of hydraulics. Toyota claims its system can make a correction in less than 20 milliseconds.

Another approach to controlling anti-roll bars is the Kinetic Dynamic Suspension System (KDSS) used by Toyota in some of its larger Lexus SUVs starting in 2004 and Land Cruisers/4Runner models starting in 2010. KDSS allows one side of the sway bay mount to move independently and disengages the bar so there is more independent wheel movement. It adjusts front and rear sway bars based on a set of interconnected hydraulic cylinders. The interconnection is made up of hydraulic piping and a control cylinder, which is located at the frame rail.

KDSS will not engage during normal driving conditions when hydraulic pressure is equal. In off-road conditions, KDSS activates when it senses that a wheel has dropped into a rut or hits an obstacle.

Repairs and Service Opportunities

Worn sway bar bushings can cause noise when the vehicle is cornering and going in a straight line. Oil leaks can often lead to the premature failure of the rubber.

The weakest points of any sway bar system are the links that connect the bar to the suspension. Designs can vary from vertical links with bushings on both ends to full ball-and-socket joints. Both of these connections can wear over time and fail. Therefore, inspection is critical.

The bar can break at the ends or in the middle. This type of failure is more common on smaller diameter rear sway bars. Also, pay attention to the mounting bushings that attach the bar to the frame.

The repair opportunities on active sway bars are increasing as vehicles age. While most of these vehicles are European nameplates, more and more domestic and Asian models are using these systems to improved stability on cars and increase off-road capabilities.

Article courtesy ImportCar.