Harmonic Dampener Diagnostics

Every time a cylinder fires, the crankshaft speeds up a very small amount for a short period of time. It is then slowed down as the next cylinder in the firing order compresses air and fuel for the next combustion event.

9 Reasons Why Harmonic Dampeners Fail

Heat The elastomeric components of the dampener turn vibrations into heat. If the heat can’t be dissipated, the rubber will fail over time. This is why you will see vents in either the wheel well liner or under tray. Cracking The outer or inner inertial mass rings can crack and cause the ring

10 Signs The Harmonic Dampener Has Failed Or Is Close To Failing

One sign is incorrect timing marks. If the outer ring has separated from the inner ring, the timing marks will move. This can been seen when comparing the timing marks on the valvetrain.

Spotting Bent Suspension Components

Normal driving usually won’t knock the wheels out of alignment or damage the suspension. However, normal driving also involves encounters with the unexpected, which often include potholes, curbs, railroad crossings (which are famous for being rough), parking lot speed bumps and other things that jar and stress the suspension.

Brake Pad Wear Sensors

Brake pad wear sensors have been around for more than 40 years. But in the past decade, they have evolved so that brake wear can be estimated. This has allowed the driver to pick the right time to have their brake pads replaced.

Brake Math: How To Stop A Vehicle With Your Foot

On a mechanical level, it is easy to understand how brakes work. We all understand that brake fluid transfers force from one hydraulic component to another. But, how does this apply to how a brake pedal feels? This is where math is required.

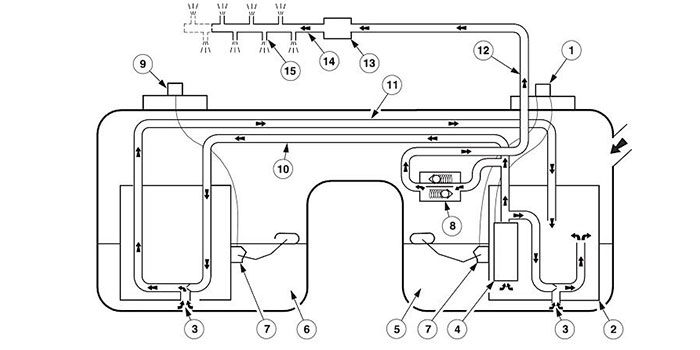

Servicing Saddle-Style Fuel Tanks

Automakers have installed saddle-style tanks on several car models for more than a decade. This style of tank uses two wells, one on either side of a driveshaft or exhaust system. This position optimizes luggage compartment capacity, fuel volume and crash safety. The behavior of the fuel wells, pumps and sending units are often misdiagnosed, leading to fuel pumps being replaced unnecessarily.

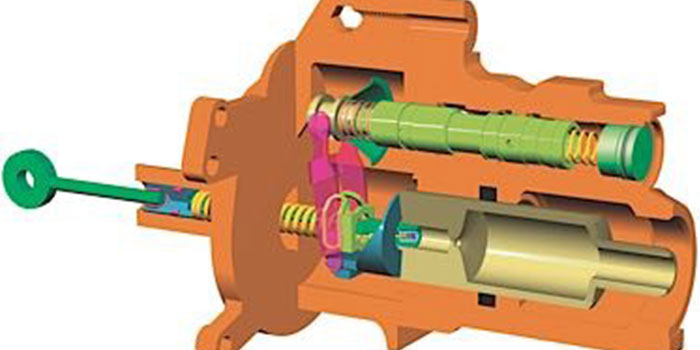

Hydro-Boost: The Non-Vacuum Booster

Hydro-boost brake boosters can be mysterious to the untrained technician because part-swapping will not solve some brake issues. These systems use the pressure of the power steering pump to power the brake booster. The booster is essentially a power steering unit that supplements the driver’s input.

GM TPMS Service Tips

Shops should use a TPMS tool that can reset the sensor positions after rotation. There is a method in the owner’s manual to “match” the sensors that involves deflating a tire for eight seconds.

Top 10 Brake Mistakes

Here are the top 10 most common brake job mistakes made by rookie technicians when replacing brake pads, rotors and calipers.

Solving Carbon Deposits In Direct Fuel Injection Engines

When the early direct-injection engines hit the three-year or 30,000-mile mark, some developed driveablity problems due to carbon buildup on the necks of the intake valves.

Brake NVH: What Is That Noise?

Friction material failure is not necessarily predictable, but without close inspection, it might be overlooked.