The BMW N54 is known for its smooth power delivery, nearly nonexistent turbo lag and robust forged internals. It’s also known to suffer from a few common issues, one of which is its electric water pump. That’s right, the water pump, the component that circulates coolant throughout the engine cooling circuit, is electric.

The water pumps we’re discussing are used in a number of vehicles. This includes the 128i, 325i, 325xi, 330i, 330xi, 525i, 525xi, 528i, 528xi, 530i, 530xi, X3, X5, and Z4. Let’s take a closer look at this unique water pump, how to replace it efficiently and what other components should be replaced along with it.

Why Electric?

Electric water pumps are becoming more and more common on modern engines. Electric auxiliary water pumps have been around for a long time. Their job is to circulate warm coolant through the heater core or to circulate coolant throughout an additional cooling circuit, such as a water-to-air charge air cooler.

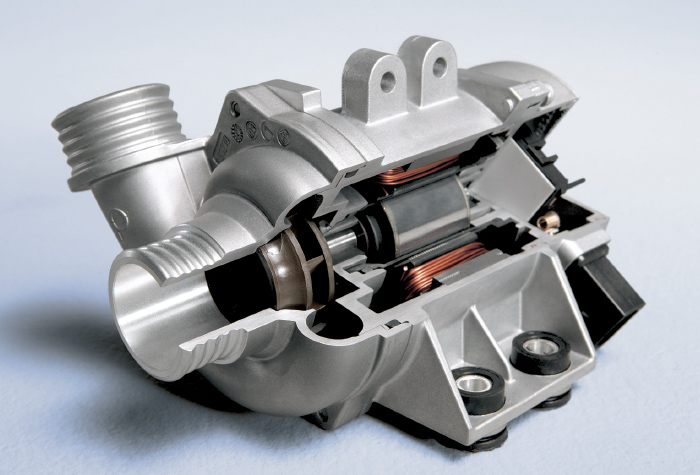

Using an electric water pump instead of the more common belt- or chain-driven mechanical pump does offer a number of advantages to both automakers and customers. The speed of a mechanical pump is directly tied to engine RPM, so the pump is able to circulate coolant only at a given rate. But since there is no mechanical link between the engine and the electric water pump, it is able to circulate coolant at whatever rate is needed based on operating conditions.

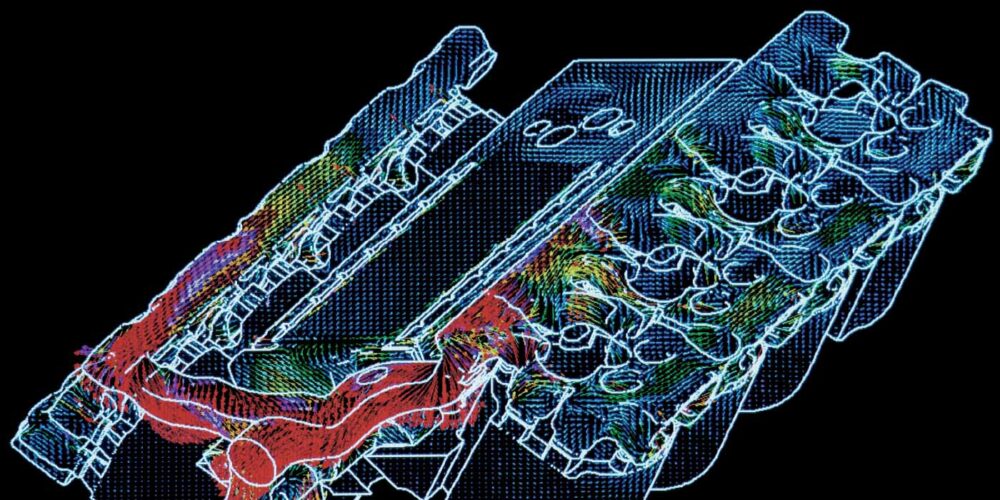

The electric water pump on the N54 has a power output of 400W, and a maximum flow rate of 9,000 liters per hour. The motor power is electronically controlled by the control module inside the pump housing, and this module is connected via the communication BUS to the Digital Motor Electrics (DME), also known as the engine control unit or ECU. The DME uses the engine load, the operating mode and the data from the temperature sensors to calculate the required cooling output, then commands the electric pump according to the current operating conditions. The electric pump regulates its speed based on this command from the DME. Coolant flows through the motor inside the pump, providing cooling to both the motor and the electronic module.

The electric water pump circulates coolant even after the engine has been shut off. Doing this can cool down the turbochargers and help to prolong their service life.

Electric water pumps on the N54 have been known to fail around 60,000-80,000 miles.

When the DME detects an issue with the pump, or if it sees engine coolant temps rising, it will notify the driver through the instrument cluster. This may take the form of one of two different messages: “Engine Temp High – Drive Moderately” displayed in yellow, or “Engine Overheat – Stop” displayed in red. The vehicle may go into “limp mode” which limits the engine RPM and available gear selection in an effort to protect engine components from damage. The electric cooling fan will usually jump to its maximum speed. You may also find stored 2E81 and/or 2E82 trouble codes, which indicate a problem with the pump.

Related Issues

There are two other cooling system issues you should be on the lookout for whenever you’re inspecting or quoting a replacement to a customer: The coolant inlet pipe, and the “Mickey Mouse” hose.

The coolant inlet pipe is an aluminum pipe with a rubber elbow on one end and an aluminum flange on the other end. The aluminum flange bolts up to the cylinder head between the turbochargers, and the rubber elbow connects to the water pump. The aluminum portion of this component should last for a long, long time, but the rubber elbow is prone to failing. This is largely due to the fact that it is mounted so close to the front turbocharger.

The real issue for customers is that BMW offers only the entire assembly; the hose isn’t available from the dealer separately. The hose clamp on the water pump side is a standard worm-drive unit so it’s easy to remove, but the other clamp is proprietary and it’s extremely difficult to remove without cutting it off. Worst of all, the flanged end of the pipe is tucked between the turbochargers, behind a number of heat shields and the downpipes.

All in all, it’ll take 6.7+ hours to replace this pipe, which feels like a waste if the rubber elbow is the only part that really failed. Thankfully, Rein offers the hose by itself, and it should take only an hour to install.

One of the many hoses which connects to the thermostat and water pump connects to the front of the engine just under the valve cover. This hose is commonly referred to as the “Mickey Mouse hose” due to the unique shape of the flange. This flange is made of plastic, and we all know how plastic parts can become brittle and crack after years of heat-cycling.

Just like the coolant inlet pipe, this flange is available only from BMW with the hose attached. Rein came up with a solution in the form of a metal replacement connector which can be purchased with or without the hose attached.