y-duty truck applications, they may also provide hydraulic boost for the power brakes. Malfunctions in either of these systems may require servicing the power steering pump.

Design Change

The problem engineers struggle with on power steering is the tendency of the hydraulic boost to insulate the driver from sensing the road surface through the steering wheel on ice-covered roadways or while driving in high-speed road course events.

During the 1980s, Honda addressed this problem by introducing a relatively simple power steering pump pressure modulation system mounted on the transaxle output shaft assembly. As axle shaft speed increased, the modulator increased steering sensitivity by reducing power steering fluid pressure to the steering rack.

Although a number of steering pump modulation systems have been produced over the years, suffice it to say that auto manufacturers have now developed computer-controlled, electronic variable orifice (EVO) power steering pumps that help adapt steering pump pressure to driving conditions.

Before attempting to diagnose any late-model power steering system, it’s important to access service data describing the operation of the system and how the system should be diagnosed. The EVO system, for example, uses vehicle speed, steering wheel position and other inputs to determine the amount of modulation necessary to produce the required steering wheel sensitivity.

As with any application-specific pressure modulation system, diagnostics requires a scan tool capable of accessing the power steering data stream and retrieving DTCs.

Finding Failures

Most power steering pumps provide ample warning of impending failure. The only exception to this would be the relatively rare instance when the pump input shaft breaks at the impellor assembly. In this case, the loss of steering assist will be instantaneous and a loss of fluid recirculation will be apparent at the power steering reservoir with the engine running.

In general, worn pumps usually provide good assist when cold, but tend to provide less assist as the power steering fluid warms up. In most of these cases, the surface of the cam ring develops a rippled surface that allows fluid pressure to leak past the vanes or rollers.

In contrast, worn metering valves in steering racks tend to provide sluggish assist when cold and return to normal assist as the assembly warms up and returns to operational tolerances.

On rare occasion, power steering assist will be stronger in one direction than the other. In these cases, the steering gear or rack might have a failed compression disk or similar steering sensitivity device in the metering valve assembly. Most commonly, the fault lies with a seized support bearing in one of the front MacPherson strut assemblies.

Diagnostic Details

When diagnosing an assist or noise problem with a power steering pump, always begin by inspecting the condition of the power steering fluid. If the fluid is dark black, the system might have a problem with deteriorating seals in the steering rack or with power steering hoses that are deteriorating from the inside out.

With the engine running, inspect the fluid in the reservoir for signs of aeration or foaming. Some Honda models are known for O-ring failures that cause the steering pump to draw atmospheric air into the pump reservoir. Foaming may also be caused by the power steering pump drawing air past a worn shaft seal during cold operation, or the steering rack drawing air through a leaking seal as the steering rack changes direction.

Some vehicles incorporate a filter or filter screen in the steering pump reservoir. If the filter is partially clogged, the pump will no longer receive an adequate volume of return fluid from the steering gear or rack. In this instance, the pump will emit a growling noise caused by the pump trying to draw fluid through the clogged filter. A similar situation can develop if a steering pump return hose is pinched or clogged. In more rare cases, the hose itself may have a strip of material peeled away from its interior diameter that intermittently clogs the hose and causes pump cavitation or the loss of pressure to the steering rack.

Always make sure that an improper fluid hasn’t been introduced into the power steering reservoir. In today’s “quick lube” market, it isn’t unheard of to see power steering reservoirs topped off with brake fluid, engine oil and other non-compatible fluids. Keep in mind that, in addition to causing foaming, non-compatible fluids may adversely affect steering rack seals, hoses and other soft components in the system. If you’re in doubt about fluid quality, the most inexpensive diagnostic procedure is to flush the questionable fluid from the system.

A power steering pressure tester is a must-have tool for objectively analyzing the power steering pump to

determine if it’s meeting the manufacturers’ fluid pressure specifications. In general, fluid pressures range from about 900 psi to about 1,500 psi. The fluid pressure tester should have a shut-off valve that allows the technician to perform a pressure test that determines the pump’s maximum pressure output. In any case, always consult manufacturers’ service data for correct testing procedures and specifications.

Recommending Replacement

Too often, technicians treat power steering pump failure as an isolated component failure rather than a system

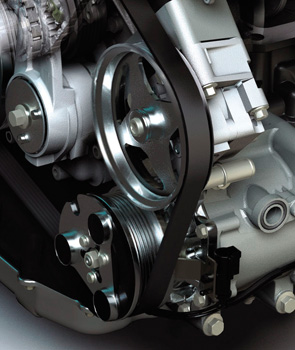

failure. After replacing a power steering pump, drive belt alignment should always be checked to ensure that the serpentine belt doesn’t roll off the pulleys when maximum pressure is demanded from the pump.

Similarly, replacing hardened and possible defective pressure and return hoses is a highly recommended practice.

Obviously, any mechanical failure in the steering pump contaminates the fluid with metallic particles. On applications with remote reservoirs, always clean the reservoir before replacing the fluid.

NOTE: If a large quantity of metallic debris is found in the reservoir, consider installing an aftermarket filter on the reservoir return hose that contains a pressure bypass and magnetic particle trap. Although these

filters are designed for automatic transmissions, they work well on power steering applications.

Next, always thoroughly flush the system to remove potentially contaminated fluid.

After flushing, cycle the steering lock-to-lock a few times. Foamed fluid should dissipate after a few minutes with the engine running. If foaming persists, many experienced technicians have had good luck using a vacuum pump with some homemade attachments to draw trapped air from the rack and hoses.

Finally, to avoid unwanted comebacks, always re-check the power steering fluid level before the

customer drives his vehicle away from the shop.