When Clayton Smith called his wife, Christine Smith, and told her he wanted to buy an engine shop, she immediately hung up the phone. Quickly realizing this was her husband’s dream, she called back and told Clayton if they were going to buy a shop, they would have to do it right.

“She said, ‘If we’re going to do this, here’s how it has to work. We’ve got to move completely over here and do it full on,’” Smith says of his wife’s advice.

The shop the Smith’s purchased in 2010 was National Machined Engine in Michigan. Clayton frequently bought engine parts and got cylinder head work done there as the shop was on his work commute from his home in Windsor, Ontario, Canada – just outside of Detroit – to Findlay, OH.

Clayton had been into cars, engines and racing his whole life, and has been a machinist ever since high school. When National Machined Engine’s former owner told him he’d be closing the shop, Clayton knew right then and there he wanted to take over the operation.

“At the time, I was looking for something else to do rather than commute from Canada to Findlay, OH every week for work,” Smith says. “Running an engine shop sounded interesting to me and we cut a deal. This was an opportunity for me to combine my hobby and my work.”

One of the reasons National Machined Engine was for sale back then, according to Smith, was the original owner went from selling parts and rebuilding engines to selling women’s clothes for men. It’s now called Janet’s Closet.

“He opened up that shop right next to the engine shop and for years tried to run both,” Smith says. “Of course, business just fell off like crazy until there was nothing left.”

Clayton and Christine immediately changed the name of the shop to Fastime Racing Engines & Parts, and stayed in that location for five years.

“Because everything was set up and running, we made a deal with him to purchase the equipment and then lease half of the building for the first five years,” he says. “At the end of the five years, we decided we’d be better off at a different location, which has been one of the better things we’ve done.”

Today, the 5,000 sq.-ft., six-employee shop resides in Taylor, MI, where the focus is on domestic V8 engines such as big block and small block Chevys and LS platforms. Fastime Racing Engines also does all its machine work in-house with the exception of grinding cranks.

“We do balancing, boring, line honing, line boring, etc. We do it all in-house because I have a machinist background,” he says. “I’m a circle track racer and I race a dirt modified, so I do a lot of circle track engine work. We also do some marine engine work because the big block Chevys are so popular.”

While Clayton manages the engine work, his wife Christine helps run the rest of the business, focusing on customer service, organizing and buying parts, accounting, and more.

“She’s the glue,” Smith admits. “I don’t know how else to describe her.”

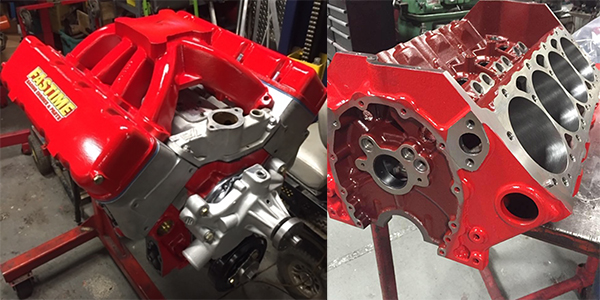

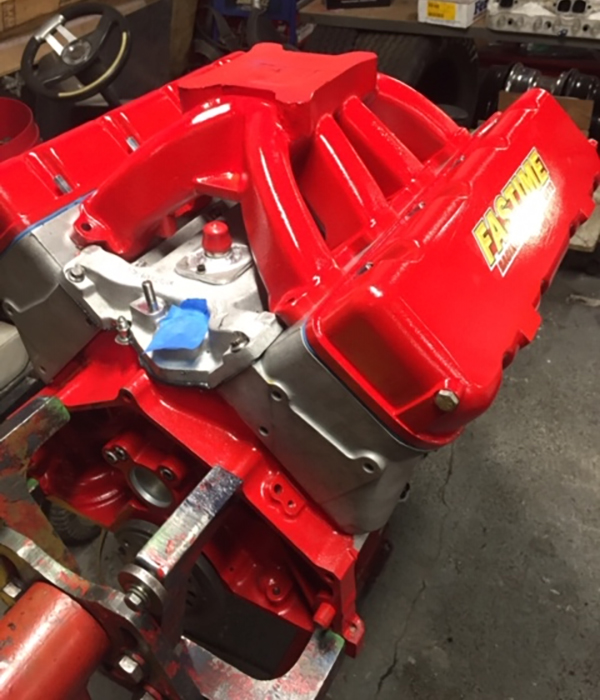

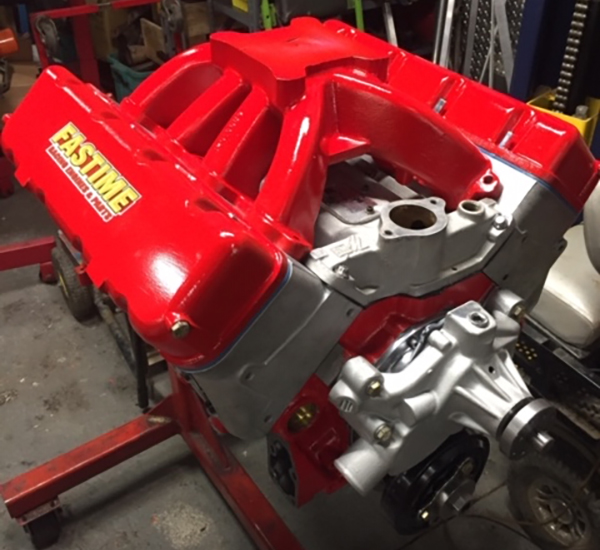

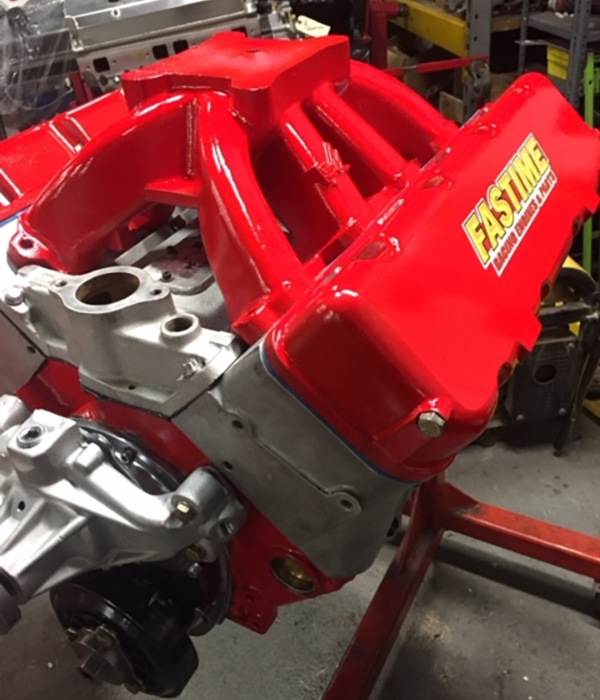

Recently, Fastime Racing Engines built a new circle track engine for Clayton’s dirt modified, and settled on building a Chevy SB2 engine.

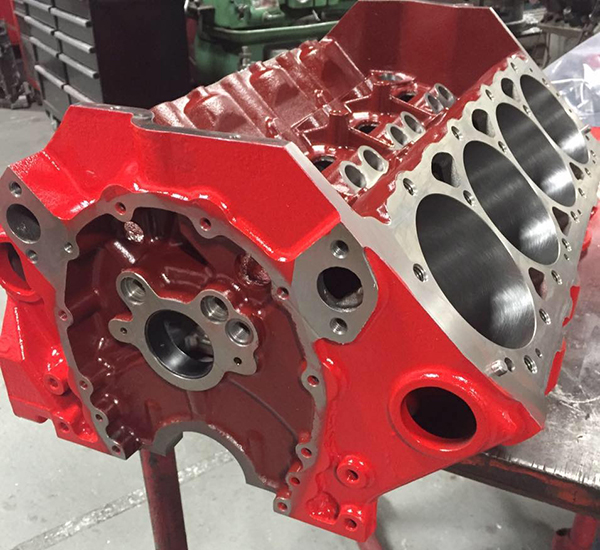

“It’s a Chevy SB2 engine with a 4.130˝ bore and a 3.875˝ stroke,” he says. “A lot of this engine came from what I had laying around. The cylinder heads were from a customer’s old Hendrick motor who decided to go in another direction. We freshened them back up and put them back together. The engine has a Dart SHP block.”

The SHP block was originally a 4.040˝ bore that the shop machined out to 4.130˝ and finished it. The heads got new seats and guides and got resurfaced.

“Because we used parts from different eras that we had to make work together, there was some shimming involved and some extra drilling of holes and custom fasteners,” Smith says.

In addition to the machine work, the SB2 engine has a Scat crank, Callies Compstar rods, CP pistons, Total Seal rings, Crower lifters, a COMP camshaft, Clevite bearings, and a billet timing set from Engine Pro.

“We chose a specific camshaft that would make the power band broader and have more torque without giving it a peaky horsepower number,” he says. “This engine won’t turn more than 8,200-8,300 rpm most of the time. Most of those SB2s like it up around 9,000 rpm, but we make peak power around 8,600 rpm. Our idea was to make a larger cubic inch with a little bit broader camshaft so that we could tone it down and keep the throttle sensitivity consistent.”

The set up for the camshaft is .775 lift on the intake, .784 on the exhaust and the duration at 50 is 259 on the intake and 269 on the exhaust.

To cap off this circle track engine build, Fastime Racing Engines poured in some Brad Penn / PennGrade oil.

“We do a lot of flat tappet engines, so we use a lot of PennGrade or Brad Penn oil,” Smith says. “Seems like that really works well for our customers. Most of them prefer it, and it’s reasonably priced for what it does.”

With this engine all ready to go, Smith says he was happy with the results.

“These engines are very capable of making a lot more horsepower, but our goal was to make it drivable for a modified, so it came out at 746 horsepower and has a pretty broad power band,” he says.

Time to head to the track!

Engine Builder magazine’s Engine of the Week eNewsletter is sponsored by PennGrade Motor Oil and Elring – Das Original.