Article courtesy ENGINE BUILDER.

One of our favorite aspects of the Engine of the Week series is seeing what all of you are building. Whether it’s a top-of-the-line, race-specific, high-horsepower beast of an engine, a vintage/classic rebuild, a street/strip build or something fun for a hot rod, we love it as much as you do.

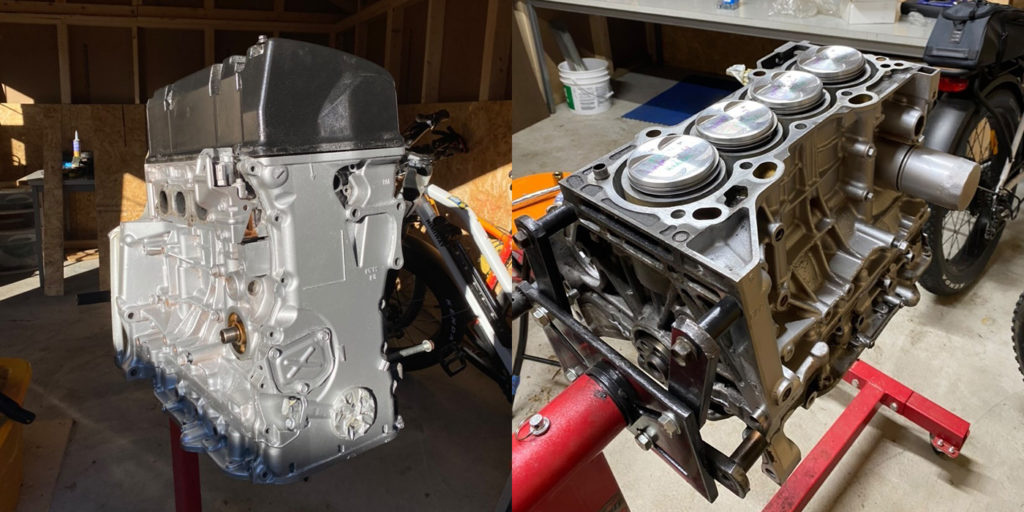

We especially like when engine builders, racers and enthusiasts reach out to us with builds they are putting together, and our latest comes from Leo Greco in Ypsilanti, MI. Leo is an aspiring, young engine builder just 17 years old, but he’s been working hard to build a turbocharged Honda K24 engine for his 2003 Toyota Celica.

“I’m 17 and this is the first engine build I’ve done in the middle of winter,” Greco says. “I’ve always liked cars ever since I was super young. I had a love for the Liberty Walk R35 GTRs since it came out. Engine building was something I got into out of necessity since I couldn’t afford to have it built by someone else, so I had to do it myself.”

Leo’s Honda K24 engine got its machine work done by Auto Parts Machine Shop. Leo had the crank cleaned and polished with some minor balancing work done to it as well. The heads were fully disassembled and hot tanked and given a full competition valve job before being reassembled.

The rest of the K24 features ACL Race bearings, new rods, JE pistons, and a ported K20 pump. “I’m hoping to have the turbo on and the engine fully sealed back up by the end of the month,” Greco says. “I should have it in the car and fully working in spring if it all goes well.”

Leo’s Honda engine should be capable of 700 hp, only limited by the stock sleeves, but he says he plans on staying around 400 hp due to the Celica being a daily driver on Michigan roads. At just 17, Leo should be in for a fun 2021 with this new K swap leading the way.

Engine of the Week is sponsored by PennGrade Motor Oil, Elring – Das Original and Scat Crankshafts.