When a wheel reacts to a bump or body motion, the spring is compressed and then releases the energy. During each compression cycle, a little bit of life is taken out of the spring’s steel. It’s not the amount of travel that matters, but the frequency of the cycles. Even under normal conditions on a smooth road, a spring can cycle an average of 1,750 times for every mile traveled. This can add up to almost 9 million cycles in 50,000 miles.

A spring’s design is tuned to many factors. Engineers will use terms like “frequency” and “amplitude” to describe spring construction. For the layman, these terms translate to how fast and how far the spring has to travel. Frequency and amplitude are tuned for ride quality, center of gravity and the sprung weight of the vehicle.

One spring rate might be great for controlling body lean, but it could be too hard to provide a comfortable ride. In an effort to increase the versatility of the spring, engineers can tune the coils to a progressive design such that the spring rate can be changed when they are compressed or subjected to certain forces.

Changing the spring rate of a coil spring is not easy. Engineers can change the spacing and pitch of the coil to generate different spring rates. They can also change the geometry of the spring by making it a barrel shape, which affects how loads are absorbed. How the spring is formed and treated can also influence the spring rate. Progressive spring designs have one disadvantage — they can fatigue in specific areas. When this happens, the spring can break.

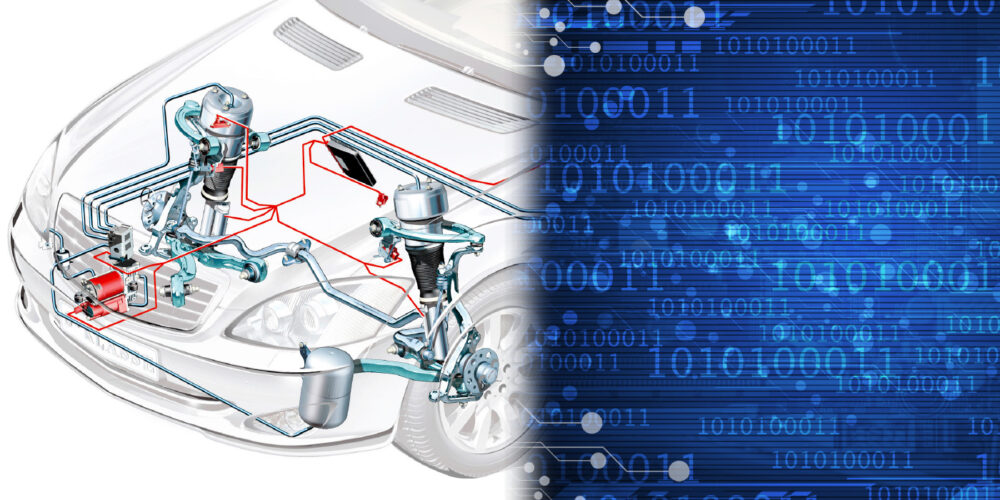

The other part of the equation is the job the strut or shock does to dampen the movement of the suspension and spring. A dampener is not a spring, and a spring is not a dampener. When a spring is compressed, it stores the energy and releases it. When a dampener is compressed, it absorbs the energy and changes it into heat. The dampener controls how the energy in the spring is absorbed and compressed. This means the specifications for the spring and strut are linked. It also means that when one component is worn, it impacts the other.

WHY SPRINGS NEED TO BE REPLACED

If you were rebuilding an engine with new heads and camshafts, would you reuse the old valve springs? Probably not, because doing so would impact performance. On some high-mileage vehicles, when the struts are replaced, the performance of the springs no longer matches that of the new strut. Similarly, when a new strut is reassembled with the old and tired spring and strut plate, the results can be less than desirable.

During the course of their service life, upper strut mounts and bearings can be hammered to death. The upper strut mount essentially supports the vehicle weight and counters both braking and acceleration torque. Most mounts are sandwiches of rubber, metal and bearings. Over time, the rubber can lose its ability to isolate the suspension from the body. Bearings can also seize and bind, causing vehicle steering problems.

Tire wear, steering and handling can also be affected by ride height and the health of the spring. If the chassis is sagging on one side, or in the front or back, weak springs are the likely cause. Weak springs can affect both camber and caster, which may result in a steering pull, a change in steering effort or return and/or uneven tire wear.

Look up the ride height specifications and measure ride height in the front and rear and on both sides of the vehicle. If ride height is less than specifications dictate, the problem is most likely one or more weak springs that should be replaced. Springs can be shimmed, but the best fix is a new replacement. Springs should typically be replaced in pairs to maintain the same ride height side to side.

Weak springs are also more likely to fail when a new strut or shock is installed. The springs on many late-model vehicles are thinner than older versions to reduce weight and have an outer plastic coating to protect the metal from corrosion. If this outer coating is cracked or damaged, corrosion can form a hot spot that eats into the spring, weakens it and eventually causes the spring to break.

The health of the springs can have dramatic effect on even seemingly unrelated vehicle components, including visibility, stopping and steering.

On vehicles without self-leveling headlights, if the ride height is down in the front, the headlights’ beam pattern will not project far enough. If the rear height is down, the headlight pattern could be pointing at the sky and blind oncoming drivers.

The electronic stability control (ESC) system measures the effectiveness of its correction made with the brake system. How effective the correction depends on the condition of the contact patch of the tires. What influences the health of this contact patch is the dampeners and springs.

The computer does not assign a value to the condition of the contact patch, and there are no parameters (PIDs) in the programming for most systems. The corrections and the effectiveness of those moves are measured by the sensors. The ESC system will try to make the smallest correction at first, and then it will escalate the corrections until the sensor and driver inputs indicate that the vehicle is back under control. If the traction level is optimal, it may actuate a dump or isolation valve for a small amount of time. If the contact patch is compromised due to a weak shock or strut, the correction may take a little longer.