New Wheel Bearing Technology Will Change Your Replacement & Diagnostic Approach

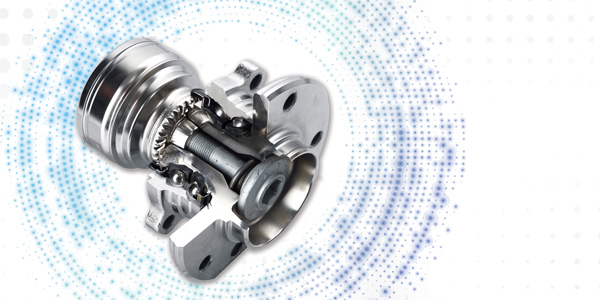

Two technologies are now being used on new vehicles and in aftermarket replacement hub units that allow engineers to put better bearings in smaller packages. These technologies will change the way you replace and diagnose wheel bearings.

How To Diagnose NVH Complaints In Drivetrain Components

Thanks to advanced technology, modern vehicles operate with fewer noise, vibration and harshness (NVH) complaints than ever before. Consequently, when a NVH issue arises, it’s most likely caused by worn drivetrain components like universal joints, constant velocity joints or wheel bearing hub assemblies. In any case, NVH complaints can often be the most challenging to diagnose when you can’t duplicate the driving conditions under which they occur.

Common Reasons For Wheel Bearing Failure

When a bearing wears out, it is usually a case of inadequate lubrication, faulty installation or improper adjustment. For the repair to be successful, you must first determine why the previous bearing failed. For sealed hub units, examining the internal bearings and races is impossible.

Wheel Bearings: Diagnostics, Removal And Installation

The classic symptom of a bad wheel bearing is typically a cyclic chirping, squealing or growling noise that changes in proportion to vehicle speed.

Spring Is Pothole And Bearing Season

The classic symptom of a bad wheel bearing is typically a cyclic chirping, squealing or growling noise that changes in proportion to vehicle speed. The sound may only appear or disappear at certain speeds. The noise may get worse when turning, or it may disappear momentarily. So, it’s difficult to make a diagnosis based on noise alone.

10 Tips For Diagnosing And Installing Control Arms And Bushings

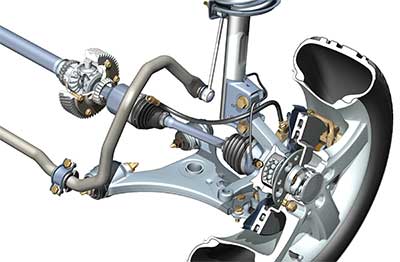

With wide adoption of large diameter wheels and low-profile tires, suspensions on late-model vehicles have changed. The extra weight of larger wheels has meant that suspension components have had to go on a diet of aluminum. Less sidewall area has transferred the role of absorbing road impacts to larger bushings in order to achieve the same ride quality.

Torque And Runout: Measure Twice, Install Once

There are two critical measurements when installing a modern hub unit or cartridge bearing: torque and runout in the flange. Ignoring these critical numbers to save time will only lead to more comebacks and angry customers.

5 Mistakes Entry-Level Tire Techs Make

Nothing can turn a new tech into a veteran but time and experience, and often that experience is going to come from making mistakes – sometimes real bad ones – and learning from them (you hope).

Component Connection: Press-in Bearings With Fewer Comebacks

Servicing the increasing number of vehicles equipped with pressed-in wheel bearings requires a little bit more finesse and tools when compared to hub units or tapered roller bearings. However, with the right tools and information, these jobs can be money-makers.

Proper Lug Nut and Lug Bolt Replacement

by Sean Phillips If there’s one thing tire techs deal with more than tires, it’s lug nuts. There’s quite a bit of knowledge and technique that goes into dealing with lug nuts and lug bolts. They’re relatively small parts under extremely large forces, and they are absolutely critical to holding the wheel on your customer’s