The Techline continues to receive calls from Technicians regarding CVT repairs. A lot of questions involve what is an applicable repair inside the CVT? This information can be found in Subaru Technical Information System. Other concerns include noises and a binding/shudder feeling. Whenever attempting to diagnose a CVT issue, the tires should be confirmed to be within specification. As little as a 1/4” difference in circumference can cause issues. Subaru recommends using a rope tape measure. If unavailable, you can use a piece of rope and standard tape measure. Wrap the rope around the center of the tread on each tire, mark it with a marker and measure the difference of markings.

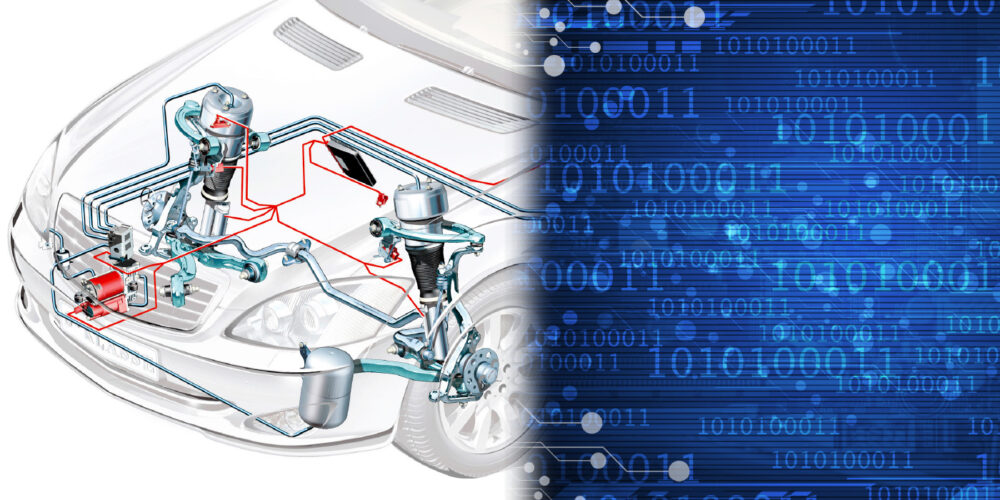

After the tires are confirmed to be within specification, move on to confirming the condition with the CVT in Front-Wheel-Drive mode. In this mode, the duty solenoid for the All-Wheel-Drive is turned off.

This mode is achieved using a scan tool. Once activated, look for a change in the condition. For example, the customer may state the vehicle is binding on turns. Tires are within specification so, FWD mode is activated to diagnose further. This would indicate an issue in the AWD system transfer clutches, which is repairable. Another example, the customer may say a noise is in the CVT. With FWD mode is activated, if the sound goes away, it may be repairable and the AWD system should be inspected. If the noise continued while FWD is active, the CVT assembly would most likely need replacement. FWD mode should be used anytime a CVT issue is being diagnosed.

If issues continue after verifying the tires are within specification and using FWD mode, use Subaru Select monitor to retrieve a drive file. Hitting the Enter button when the issue occurs will put a mark in the file.