The engine thermostat has been an important component in automotive internal combustion engines for almost a century. The engine thermostat helps to speed warmup and reduce cylinder ring wear. Today, the engine thermostat plays an important role in increasing engine combustion efficiency and reducing emissions. To accomplish that task, engine thermostat functions are controlled by the engine’s electronic control unit (ECU), ensuring precise regulation of temperature based on the engine’s loads.

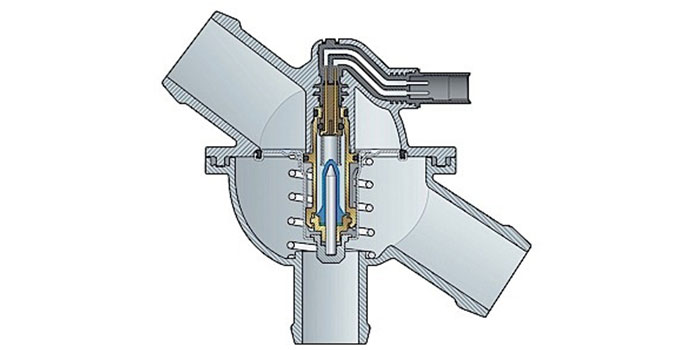

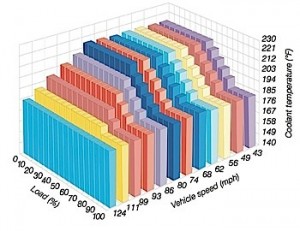

An electrically assisted (also called “map-controlled”) thermostat provides broader and faster operation than the traditional engine thermostat. In addition to the mechanical function of the wax element, electrically assisted thermostats incorporate an electric heater within the sensor. This heater is controlled by the vehicle’s ECU, which receives information on the speed and load conditions of the engine. It uses this information to regulate the temperature of the coolant. A data set, or “map,” is stored within the ECU to govern when and how heat is added to ensure optimal engine performance.

The experts at MAHLE Aftermarket offer these tech tips for working with electrically assisted thermostats:

• As is the case with the conventional engine thermostat, electrically assisted thermostats are not subject to material wear; they are maintenance-free and designed to last for the entire engine service life. However, external factors such as the use of low-grade coolant, and failure to regularly service the coolant can lead to material failure.

• Other possible causes of engine thermostat failure include previous damage caused by thermal overloading or contamination due to work carried out on the cooling system, for example when replacing the coolant or water pump, the cooler, the coolant hose, timing belt or V-belt.

• It is important for technicians to remember that the map-controlled thermostat is only part of a more complex cooling system consisting of coolant passages in the engine, a coolant mixing chamber around the thermostat, coolant hoses, a radiator, electric fans and the actual coolant.

• When replacing faulty parts in the cooling system, thermostats and/or integral thermostatic housings should also always be replaced at the same time because any loss of functionality (or even complete failure) can have severe consequences, including engine damage.

Courtesy of MAHLE Aftermarket Inc.