When you fix cars for a long time, you hear some crazy stuff – like putting cornmeal in the radiator to stop a leak. It’s true. That used to be one of the “backyard” remedies floating around. I hate to earn the “Captain Obvious” nickname, but I’m willing to take the chance. So just in case, before I go any further, let me be clear: Do NOT do that.

Another old falsity that used to float around was that if your thermostat was stuck, causing engine overheating, all you had to do was simply remove it. In an emergency, this would at least get you home, but again, not an acceptable repair. This one, however, is at least understandable as we get into the evolution of thermostats.

The majority of early automobiles utilized a cooling system known as a thermosyphon system. There was no thermostat or water pump. The hot coolant would rise upward through the engine, out through the upper radiator hose and into the upper radiator tank. Water becomes denser as it cools, and as it did, it would fall downward through the radiator, into the lower tank and then back into the engine.

This type of system worked fairly well for the time, but heavy use often caused overheating, and the use of a thermostat and water pump was a necessary advancement as cars got heavier and more powerful.

Bellows-Style Thermostats

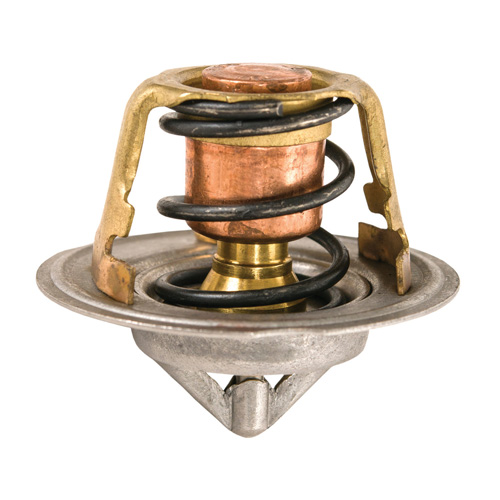

Leaving out a few obscure short-lived designs, early thermostats utilized a bellows system (see Figure 1). Inside the bellows was a liquid that, when heated, would change into a gas. As the liquid boiled and changed to gas, the bellows would expand, opening the valve to allow coolant to flow. These were susceptible to failure, and they also were affected by pressure changes. This was not a problem early on, because early cooling systems were not pressurized. Once we began to utilize pressurized cooling systems, the pressure built in the system sometimes would force these shut and cause overheating.

The solution was the wax-style of thermostat (see Figure 2) in which the wax changed from a solid state to a liquid, eliminating the pressure effect on the previous liquid-to-gas style. A piston in the wax pushed a rod that opened the valve. A spring was utilized to force the valve shut as the wax cooled and returned to a solid. This style of thermostat became the standard thermostat of the time, and by the 1960s was the primary thermostat in use for new cars, as well as direct replacement for any that still had a bellows-style.

Double-Valve Thermostats

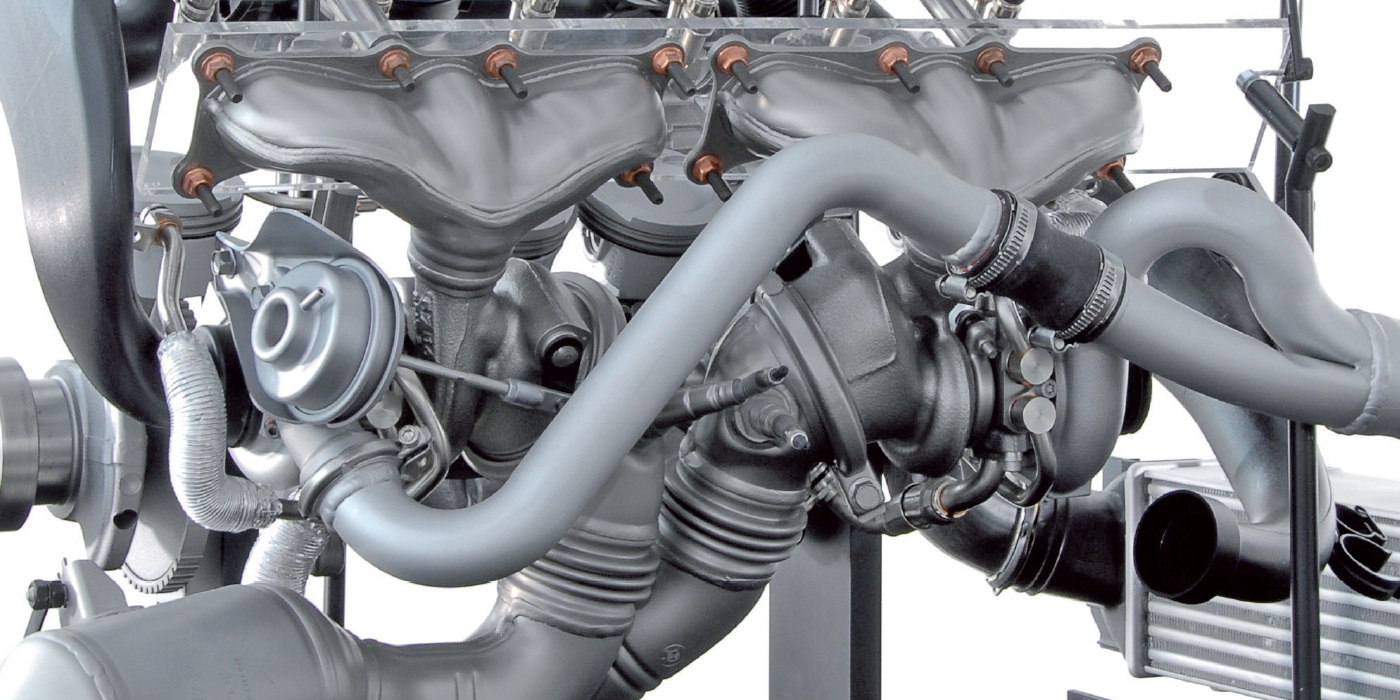

While this overall design stood the test of time, there was one evolutionary change to it with the double-valve thermostat (see Figure 3). The double-valve thermostat, in conjunction with cooling system design, allowed more precise temperature control. To understand this, you first have to understand thermostat bypass. It is beneficial for coolant to flow through the engine when the thermostat is closed – to eliminate hot spots, allow the engine to warm up evenly, improve fuel vaporization and allow sufficient warm coolant to flow past the thermostat so it opens when needed.

Although various different bypass designs were used on early thermostat-controlled systems, most American cars in the 1960s utilized an open bypass (a whole other article) along with the traditional wax thermostat in Figure 2.

Fuel injection, fuel economy and reduced emissions demanded more precise temperature control, and that’s where the double-valve thermostat came into place. When the thermostat is closed, it allows all the coolant to circulate back through the engine to provide an even warm up. As the thermostat begins to open, it allows some coolant to flow to the radiator, yet some to circulate back into the engine. When the temperature rises above a certain point, the thermostat opens fully, blocking the bypass and sending all coolant to the radiator. This overall operation allows the engine to remain at a very consistent operating temperature by preventing a drastic hot/cold change each time the thermostat opens.

A review of what a thermostat does is the best way to understand why they’re so important on today’s engines. By blocking coolant flow to the radiator, it allows the engine to warm up quickly, which is important for drivability, heater performance and emissions. The thermostat opens fully at a specified temperature to allow coolant to flow into the radiator. A thermostat rating is part of cooling-system design because they also must give the coolant enough time in the radiator to cool off. Installing a cooler thermostat doesn’t always mean the engine will run cooler. Even more critical as engine-management technology continues to advance, extremely precise control of engine temperature is necessary to maximize fuel economy and minimize emissions.

Electronically Controlled Thermostats

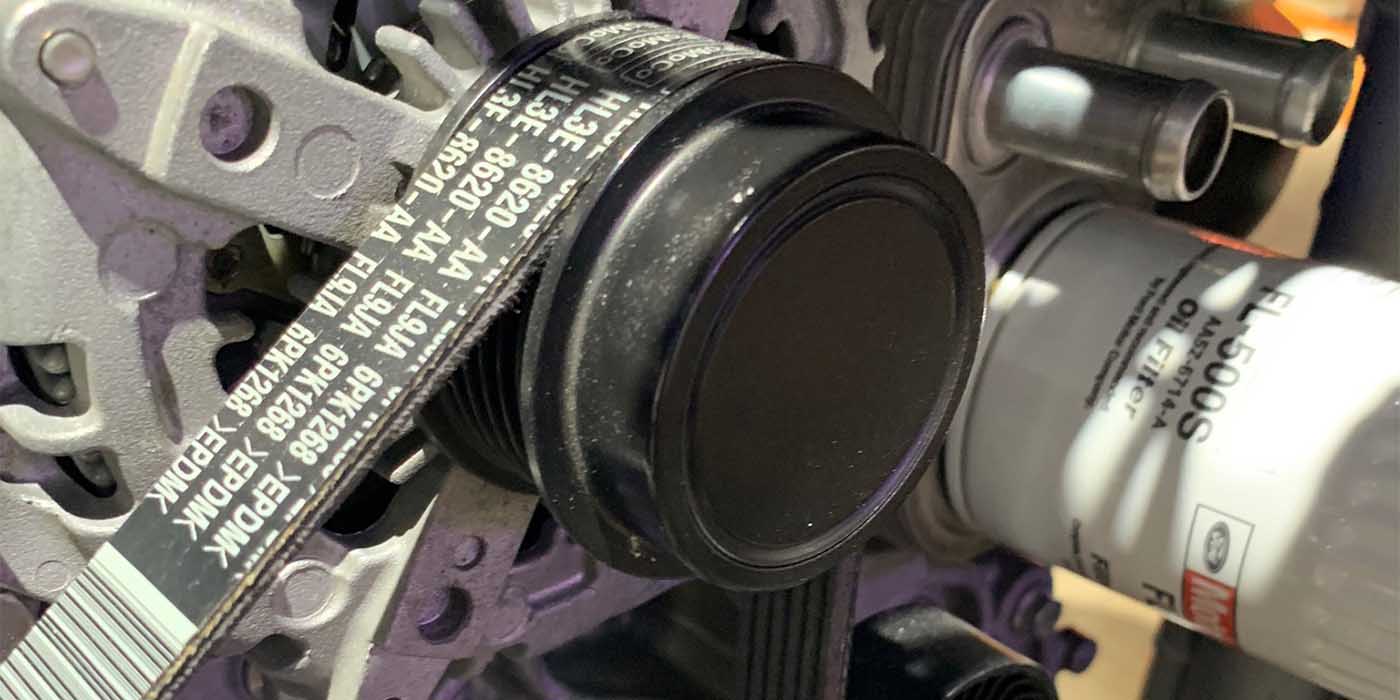

This need for this precision brought about the latest thermostat in the evolutionary chain: the electronically controlled thermostat (Figure 3). Fuel economy, power output and emissions all are affected by engine rpm, load and temperature, and to obtain the highest efficiency possible under all operating conditions, we must have infinite control over temperature. With the electronically controlled thermostat, the vehicle computer now has that control.

Their operation is almost exactly what we’re already used to. They’re still wax-operated but designed to open at a failsafe temperature to keep the engine from overheating. The electronic part is a heater that heats the wax to cause the thermostat to open or close exactly as needed. If the electronic circuit fails, the thermostat still will open in time to prevent overheating. An electronic thermostat requires a scan tool for circuit monitoring and control during diagnosis. Coupled with other cooling-system advancements such as electric fan control, variable-flow coolant pumps and active grille shutters, it’s safe to say modern cooling systems are dialed in. It’s a far cry from throwing the thermostat out and dumping in some cornmeal.