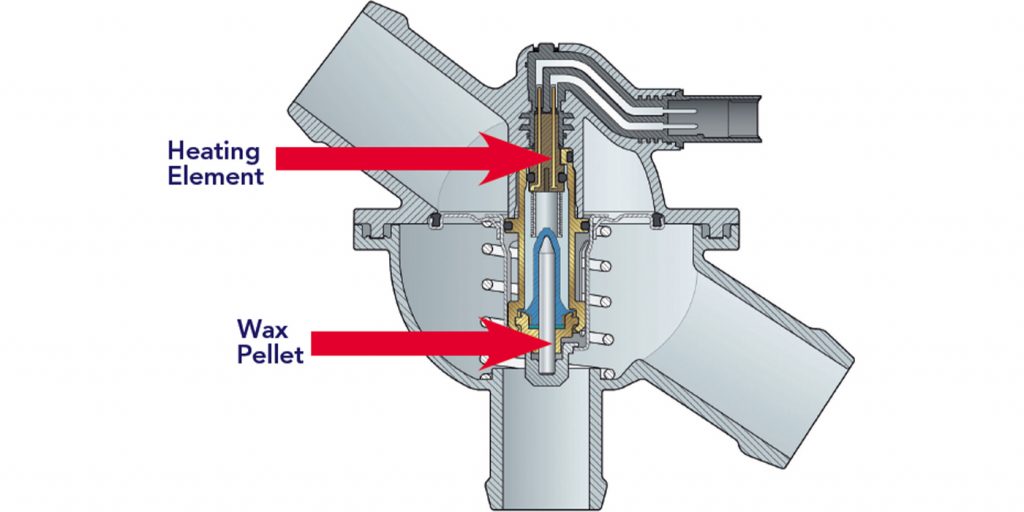

An electrically controlled thermostat still uses expanding wax, but it controls the temperature of the wax. To do this, it uses a heater coil surrounding the wax capsule — no fancy stepper motors or plungers.

When the heater or driver circuit fails on an electronically controlled thermostat, the thermostat becomes a conventional thermostat and will not cause the engine to overheat. However, the engine will know it has failed and will generate a code.

The majority of vehicles with an electronically controlled thermostat have a thermostat module, housing or unit. On the side of the thermostat housing will be a connector that you might assume is a temperature sensor. Like a coolant temperature sensor, it will have a two-wire connector.

One wire will be a ground and the other will supply voltage to the heating coil. The voltage to the coil will be regulated by the engine management system. Some systems will turn the voltage on or off as needed. Some systems will use a pulse-width modulated signal to control the temperature like a heater on an oxygen sensor.

On these systems, there are two ways the engine management module knows there is a problem. The engine module is able to determine if there is a short or open like a heater circuit for an oxygen sensor. It does this through measuring voltage drops to determine if the circuit and component are functioning normally.

If the heater circuit is no longer able to control the wax, the lack of change can be detected by the coolant temperature sensors on the block, head and radiator. When the engine management module detects this condition, it will set a code.

When the heater circuit fails, most of the time it will create an open circuit. In some cases, the opening might not occur until the engine is warm. Keep this in mind if you clear a thermostat or coolant-temperature-related code.

With the average electronically controlled thermostat module costing more than $130, it is critical to test the component and circuit before installing a new part.

The first component to check is the circuit. If the system has a code for an open or short in the circuit, clear the code. If the code comes back immediately, you have confirmed the problem, unless the problem is in the heater coil or the circuit on the vehicle. You can determine if the coil is bad by measuring the resistance in the component. If it is open, the heating coil is damaged. If it is not open, measure the resistance and check the specification in the service information.

You can also use an amp clamp to determine if the engine management system is sending voltage to the component. These systems can either be ground or positive voltage switched. You can also see the switching if you have a scan tool that can watch this data. Some scan tools can even bidirectionally control the heater circuit.

VW has a testing method for some vehicles that is very similar to the pot of boiling water test to see if the thermostat is opening. It involves sending battery voltage to the thermostat while it is submerged in hot water. They warn that if the heater is not submerged during the test, it could be damaged. This method will not work on all units when the thermostat is buried in the housing.

Courtesy of MAHLE.