Article courtesy Brake & Front End.

Look at Ride Height

Suspension angles are dynamic. As the body and suspension moves, the angles will change in the front and rear. OEMs tune these angles for the best tire wear and stability at a set ride height.

If a spring is weak or missing a coil, the alignment angles will be off these calculations.

Compare Side to Side

Sometimes a bent component is difficult to spot with the naked eye. If you see a caster, steering angle or SAI reading that is off, compare components on both sides. The key areas to observe are the steering arms, strut mounting points and control arms. Most chassis parts are designed to bend at strategic points to prevent damage to the frame or unibody in the event of a crash.

Don’t Forget the Tires

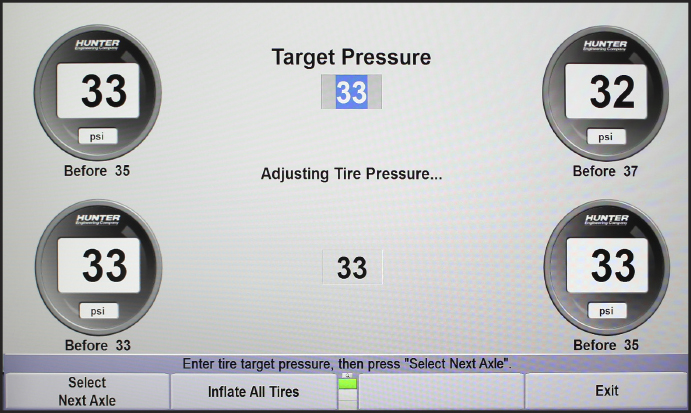

When doing your pre-alignment inspection, always check and set tire inflation pressures. A low tire will cause a pull, and a car also will pull toward the side with the smallest or widest tires. Another factor that could cause a steering pull are variances in the construction of the tires. These types of problems can be diagnosed using a balancer that can measure the rolling forces in the tires.

Check TSBs

TSBs for alignment issues often have titles referencing tire wear and steering pull complaints. The majority of the TSBs focus on warranty procedures and reimbursement. But, read between the lines and you can find the truth. One Nissan TSB even told technicians to align a vehicle as close as possible to the specifications and ignore the tolerances. Another Honda TSB told technicians to pay attention to plant codes and production dates of a particular tire size and brand to cure a steering pull.

Doubt the Bushings

Suspension bushings may have increased in size, but these bushings can still wear to the point that they will change alignment angles. On the alignment rack, the angles might be within specifications, but loads are put on the bushing during braking, accelerating and corning that could change those angles. The most common sign of a worn bushing is inside edge tire wear and negative toe out.

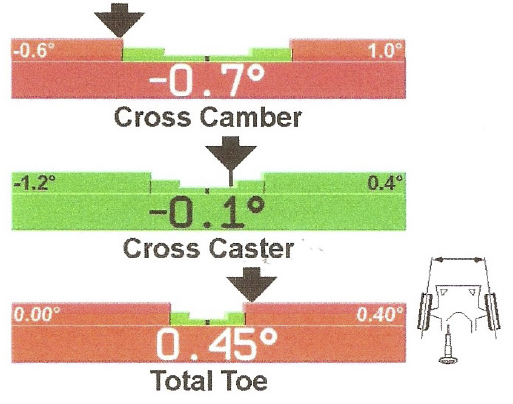

Going Green Is Not Always Best

Even if all of the angles are in the green, the car may still have an alignment problem. Interpreting the angles and thinking about how an angle on one side can “add up” to trouble on the opposite side is critical for avoiding comebacks. Positive camber on one side with negative camber on the other can add up to a pull even if the specs are within tolerances because ±5° on both sides can add up to 10º.

Calibrate and Finish

Many vehicles require that the SAS be reset or recalibrated after an alignment is performed or parts in the steering system are replaced. There are three types of reset procedures: systems that self-calibrate on their own; vehicles that require specific wires or buttons be pressed; and systems that require recalibration with a scan tool. If the SAS is out of calibration, most vehicles can tell if they’re traveling in a straight line. But if the angle is too far off, the ESC could become disabled. Some newer vehicles can automatically calibrate by having the wheel turned from lock to lock and then centered and cycling the key. There are many options for scan tools to reset SASs. Some tools are even integrated into an alignment system. But, most tools recommend that the calibration be performed on a level surface. Also, it’s a good idea to perform a lock-to-lock turn to complete the calibration.