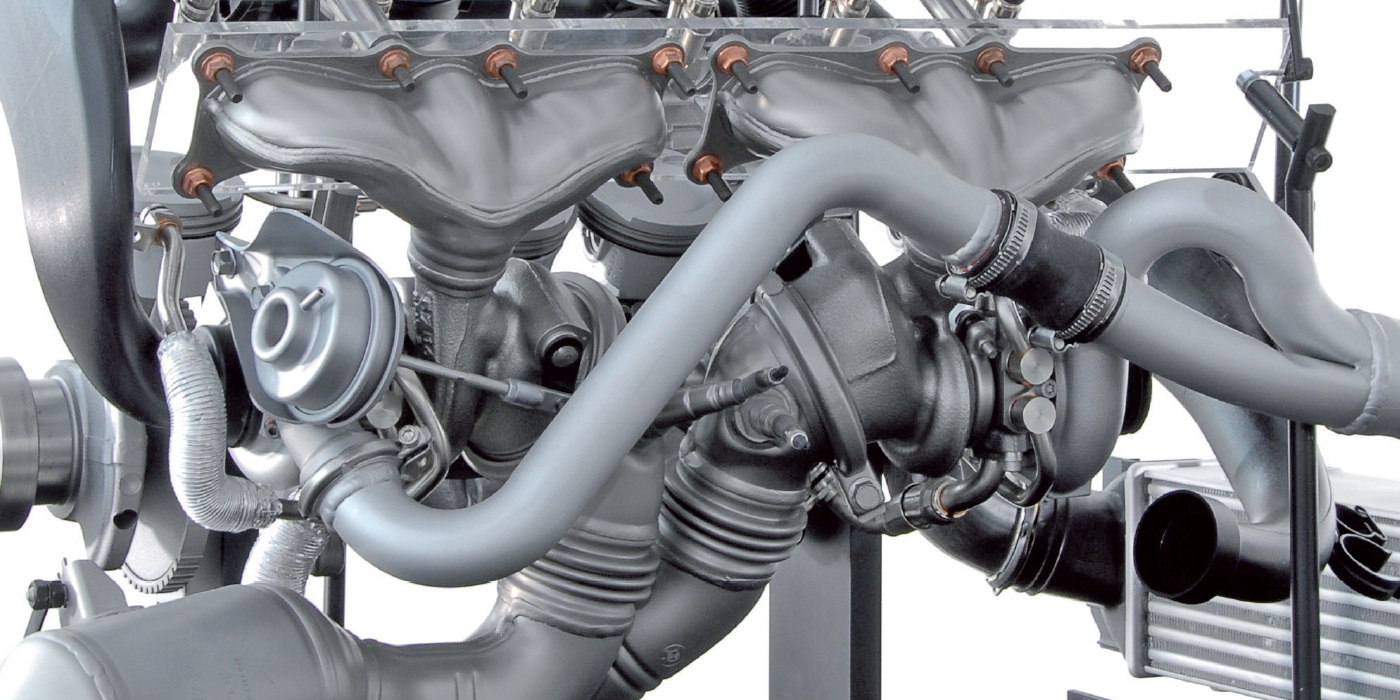

Almost every part on the engine determines how long a catalytic converter will last. It could be a faulty line of computer code that pulses an injector too long, or it could be a stuck piston ring that allows oil to be sucked into the combustion chamber. These little details can limit the life of a catalytic converter.

Platinum, palladium, rhodium and cerium store oxygen in the converter during periods of lean operation or by an external air source. The oxygen is used to oxidize hydrocarbons and toxic gases during periods of “rich” operation. This oxidation changes harmful carbon monoxide (CO) into carbon dioxide (CO2). It will also oxidize hydrocarbon or fuel by turning it into inert carbon products and water (H2O). This is called “reduction” in chemistry, breaking down molecules into smaller parts. The precious metals act as catalysts in the process and are not changed; they just store and use oxygen to break down combustion products.

However, they can’t break down or oxidize some chemicals in the exhaust stream. If the catalyst is blocked by carbon, silica or phosphorus, the converter will fail to work.

For a catalyst efficiency code to be set, a number of criteria must be met. The specific enabling criteria are different for almost every vehicle. For a code to be set, the oxygen or air fuel sensor and the rear oxygen sensor must see a reduction in the efficiency of the converter. In other words, if the oxygen levels before and after the converter do not change, the converter is not working.

But, this is not an automatic pass or fail. The oxygen sensors need to see this loss in efficiency over a number of drive cycle conditions. This is why it might take a few hours or a few days for the light to come back on after an efficiency code is erased and no other service is performed.

On most vehicles, an efficiency code will not be set if an oxygen sensor heater code or any oxygen sensor-related code is set. The same is true for coolant and air temperature sensors. You could repair these items only to have the customer come back with the check engine light on and an efficiency code set.

What is Efficiency?

The converter has an efficiency rating that is computed by the vehicle. This number rates the amount of reduction that is occurring in the converter and its ability to store oxygen. But, efficiency of the converter is tied to the fuel trim of the engine. Most engines minutely alter the fuel trim to replenish the oxygen in the converter and to add fuel for reduction. This helps to keep the converter at the correct temperature for the most efficient operation.

If an engine is running too rich, it cannot store oxygen. If it is running too lean, the reduction process might not occur due to an inability to heat up.

If the engine is dealing with a leaking vacuum hose or a stuck injector, it can’t switch the fuel mixture properly to replenish oxygen and reduce harmful contaminates.

Converter efficiency can be checked with some scan tools along with the switching between rich and lean. Lab scopes can also be used to monitor the switching. The converter efficiency threshold of a vehicle is part of a vehicle’s software. Once the efficiency drops below a specified level and other criteria are met, an efficiency code will be set. The software is designed to filter out data that may be erroneous or random signals that may interfere with the oxygen sensor.

Most converters start out at about 99 percent efficiency when new, and quickly taper off to about 95 percent efficiency after about 4,000 miles. As long as efficiency doesn’t drop off more than a few percentage points, the converter will do a good job of cleaning up the exhaust. But, if efficiency drops much below 92 percent, it will usually turn on the MIL lamp. With vehicles that meet the tougher LEV (Low Emission Vehicle) requirements, there’s even less room for leeway. A drop in converter efficiency of only three percent can cause emissions to exceed federal limits by 150 percent. The LEV standard allows only 0.225 grams per mile of hydrocarbons, which is almost nothing. Courtesy Brake & Front End.