Pro Touring is the niche of niches in today’s performance world — and why not, since it’s pretty much anything goes with these unique machines.

The fundamental theory behind Pro Touring is to take a car that is not historically significant and update the handling and performance with today’s modernized parts and assemblies. It’s the old idea of putting modern components in an older car.

But Pro Touring is also about real results, not just looks. These cars and trucks are all about actually running hard and fast. Many shows have a small track with a slalom course where the latest Pro Touring rides run against the clock for trophies and bragging rights. No straight line drag racing with these cars, carving corners is what matters. So, because actual wheels-on-the-ground performance is such an important aspect of these cars, engines are one of the biggest factors when building them.

Typically, the tracks they run on are just about all turns, with very little straightaway, so engine requirements include quick revving and delivering power to an upgraded chassis and suspension. The power curves used are low-end work, not top-end, like other kinds of racing.

One aspect that does transfer from other types of racing is keeping the car light so it can remain agile on the track with a good power-to-weight ratio. That means the powerplant factors into the overall chassis design and helps another important factor of a Pro Touring build, handling. It’s safe to bet when the best of these cars are being built, they’re formulated like race cars.

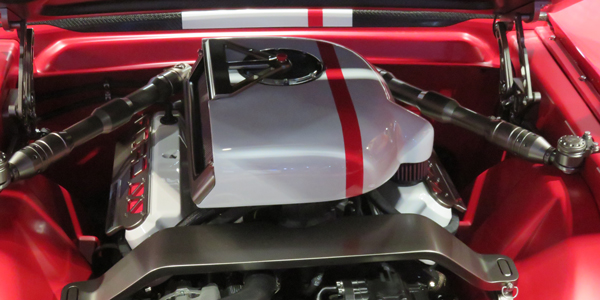

While a number of different engines are used these days, there seems to be one engine that just keeps surfacing. It’s no surprise the aluminum LS platform is the leading bullet for Pro Touring. It’s the SBC of today, and if built right, it can be as light as it is fast.

Frank Beck, president and CEO of Beck Racing Engines in Phoenix told us, “For a Pro Touring application, the LS engine has been the dominant force as it is not only powerful, but lightweight. The lighter weight engine tremendously helps with weight distribution and handling.”

Mike Bell is co-owner of Powerline Engines in Mentor, Ohio, and agrees. “Obviously, the LS swap is probably the most popular, but I would not call that new. It’s almost old now. We try to make ours different so it isn’t just an everyday engine.”

Despite its popularity, and despite the fact LS work is strong business, Bell says it seems like it’s now a “been there done that” type of thing. “I could be wrong but it just seems like it gets old, seeing a LS in an old muscle car. We try to shy away from ‘traditional’ LS stuff, although we do a lot of it and we also do the swaps in-house.”

Bek sees a lot of LS builds coming out of his shop destined for Pro Touring cars. “Our most popular Pro Touring engine is our 416 LS3 Street Kill,” he says, citing a typical recipe. “All our LS NA ‘Street’ engines run on straight 91 octane pump gas with hydraulic rollers and are capable of running AC, PS, PB, and driving coast to coast,” he says.

The accessories are another factor many Pro Touring builders and customers want that have to be factored into the motor specs. On the other side of the market, many Pro Touring builders don’t have those options and build the engine and car more like a real race car.

The variety means giving customers what they want for their individual Pro Touring machine, and that makes it virtually the same as any other customer order.

“As in any engine we build, we spend a lot of time asking the customer a list of questions about their vehicle, application, wants, needs and budget,” Beck says, adding, “When we build a Pro Touring engine, first off, it depends on the customer’s budget of course. When we build one, we want to mix max performance with streetable reliability with a touch concentrated on fuel economy because we know these cars are going to go a distance and not just be driven around local.”

For his basic recipe of a good Pro Touring engine, Bell includes, lightweight rotating assemblies and cams that push the limit for the street, but still maintain a good idle quality.

“Drivability is the main concern and it has to be smooth and easy to drive for the most part,” he adds. “Again, it depends upon the customer. We think fuel injection is a must as it allows us to fine tune the engine on the dyno so that it is easier to drive. We also push for forced induction if the customer can afford it.”

Specifically, Bell shares that the base of the engine will almost always start out with a new aftermarket block — Dart or World.

“We normally install a custom Callies crankshaft with the smallest journals that we can run,” he notes. “Honda or IRL sizes are what we shoot for. We always use custom Diamond pistons with a .866˝ pin. Rarely do we use an off-the-shelf piston. Rods will either be Crower or Carrillo and we like to use a little longer rod than a lot of guys do. It’s just a preference. Heads will always be CNC ported, but the brand depends on the project budget. Normally, we run a Jesel belt drive with a custom ground, Comp camshaft. Again, we rarely use an off the shelf camshaft. Basically, we try to run all of our own specs so that it is our build and not just an off the shelf engine.”

But when a customer wants to go hardcore with lots of overkill on an engine build, what happens then? Bell says their higher-end customers typically want the same thing as the rest of their Pro Touring clients.

“They are looking for the most power and the easiest to drive on the street, budget not being important usually,” Bell says. “I would say all of the higher-end clients will go with a supercharger or a turbo set up, but it has to idle properly and drive smooth. Don’t get me wrong though. There are the guys that want that cam so lopey that it barely idles. I have also had guys tell me that the lope and the sound is more important than the performance.”

“For the customer that wants more, the next step up is supercharging. I prefer a screw blower such as a Whipple. Quick throttle response, TONS of low-end grunt, probably too much for most vehicles and tires to handle,” Beck adds.

An engine like that is another dimension. Would it still be somewhat streetable? Beck has that covered. “On our Pro Touring ‘Street’ boosted applications we use 91 octane pump gas with a custom water methanol injection manufactured by Snow Performance for us,” he says. “This substantially cools the air inlet temperature, boosts the octane and acts as an additional intercooler.”

And you know somebody is going to ask for even more. “For the ultimate in HP, nothing beats a pair of hair dryers. There again, we add the water meth system to those as well,” he says.

Bell also builds all aluminum big blocks, which he says are becoming popular for the “power mongrels.”

“We also offer mechanical rollers, high compression race gas and exotic head combos for additional power as well,” he explains.

The quick and dirty of a monster motor is the same across the country, Beck says, adding, “Speed costs: how fast do you want to go?” A common problem is reminding the customer that, in this kind of application, there is only a small range of power being delivered properly.

“The engine is only one piece of the puzzle,” Beck explains. “If we don’t supply them with the parts or service, we do whatever we can to steer them in the right direction so they get the right stuff the first time.”

The Pro Touring movement is as varied and different as we mentioned, but it continues to include bigger, better engines.

“The latest trends always seem to be that they want more power. Most have never experienced an honest 600, 700, 800 or 1000 HP, but think they need it,” Beck says.

Bell explains another fashion: “People are taking new Mustang GTs, Camaros and ‘Vettes and bolting an exhaust on them, maybe some wheels and calling it a Pro Touring car. But the true Pro Touring car to me is an older car with all the suspension mods, wheels, lowered, later model en gine an exhaust.”

Engines for Pro Touring are evolving just as quickly as the cars themselves. It seems that as hot parts come out, they quickly find their way onto the very latest builds.

Adapted from an article in Engine Builder.