When Kyle Whetsel and Brad Simoneau were college roommates at the University of Northwestern Ohio (UNOH), they didn’t know their friendship would eventually extend into the workplace. However, that’s exactly what happened more than 10 years after graduation.

Brad attended UNOH because of his lifelong passion for manufacturing and engine machining. After graduating, he spent 11 years working for the Engine Factory in New Jersey. During that time, he and Kyle managed to stay in touch.

Kyle had started working at an engine shop in Florida’s panhandle called RPM Performance and Machine in Fort Walton Beach, FL. The shop’s owner was looking to retire from the business, and although Kyle had only worked at RPM for a year, he couldn’t pass up the golden opportunity sitting before him, so he decided to purchase RPM Performance and Machine. The stars were about to align for Brad and Kyle to reunite.

“Kyle bought RPM from the previous owner in April 2015 and maintained the shop’s name,” Simoneau says. “He pretty much started from scratch because after the owner left, it was just Kyle here working by himself. Then he started hiring more people and he finally got to the point where he needed another engine builder and he started bugging me.

“After 11 years, I was getting tired of the weather in New Jersey, so I moved down here [to Florida] and Kyle hired me on. I’m a lead machinist and engine builder here at RPM Performance and Machine.”

Kyle took over RPM almost five years ago now, and Brad started at the shop in August 2018. The shop has five full-time employees, and according to Simoneau, RPM is the only engine machine shop in town.

“We do anything and everything that hits the door,” he says. “We do anything from just rebuilding a customer’s cylinder head to big horsepower boat motors. We’re starting to branch off into the turnkey market and doing a lot with LS engines. We also do a lot of FE motors. That’s a big market for us as well. We also see the 351 and 400M Clevelands and we do some outboard marine engines, Merc cruisers, and small block and big block Chevys.”

RPM is able to tackle all those different builds and do anything that walks in the door because the shop is a full machine shop capable of doing all work in-house.

“We’ve got an RMC CNC mill we do all of our block work and head work in,” Simoneau says. “We’ve got a Sunnen CV 616. We’ve got a Winona Van Norman seat and guide machine – it’s a full machine shop and we’re capable of doing anything that comes in. We also have a Dynojet chassis dyno and an engine dyno.”

Recently, RPM had a new customer find the shop by way of its turnkey engines. He was looking to put a new engine in his ’76 F-150.

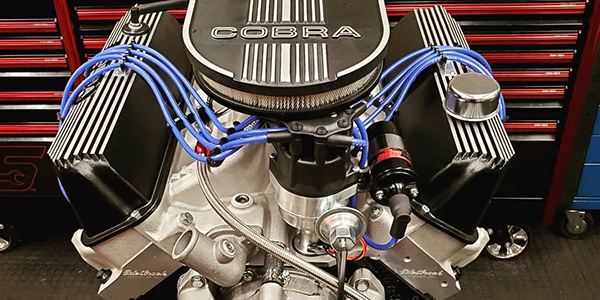

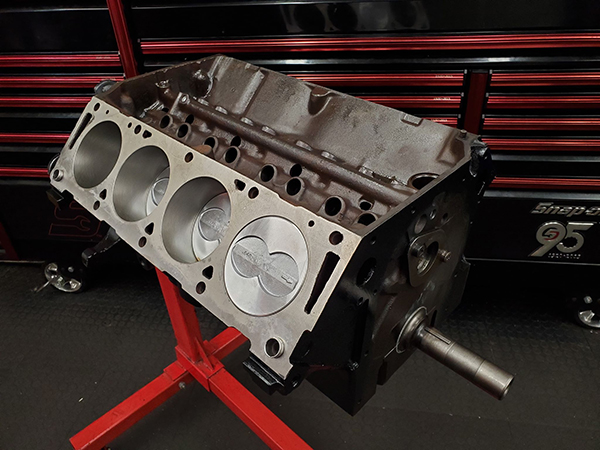

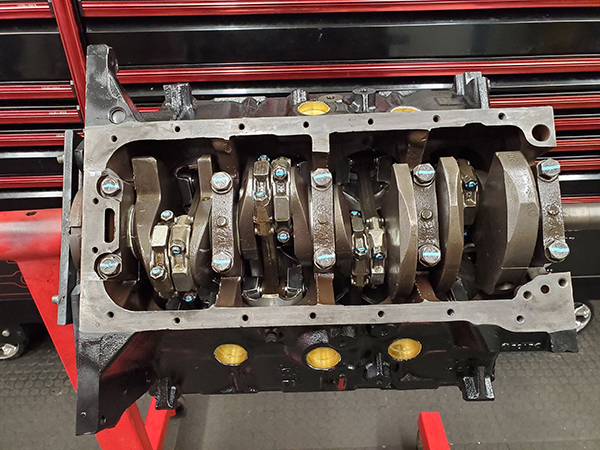

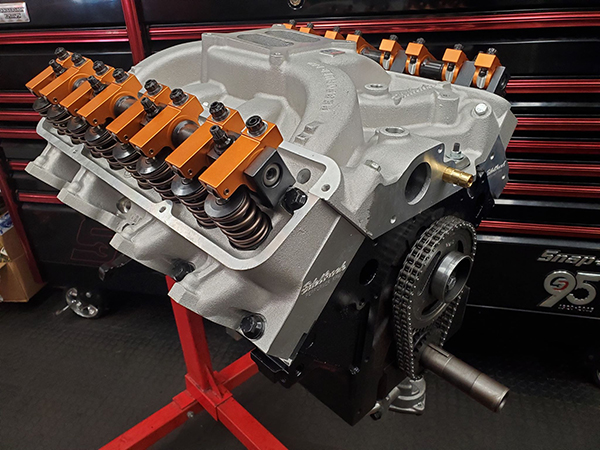

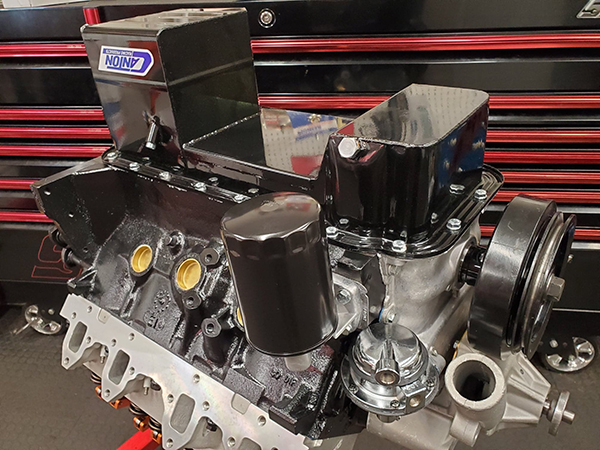

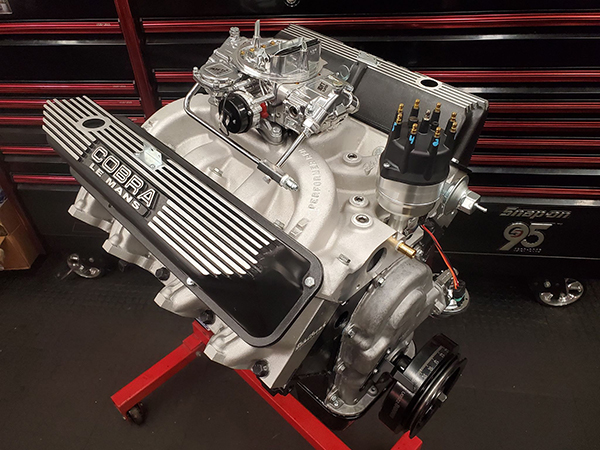

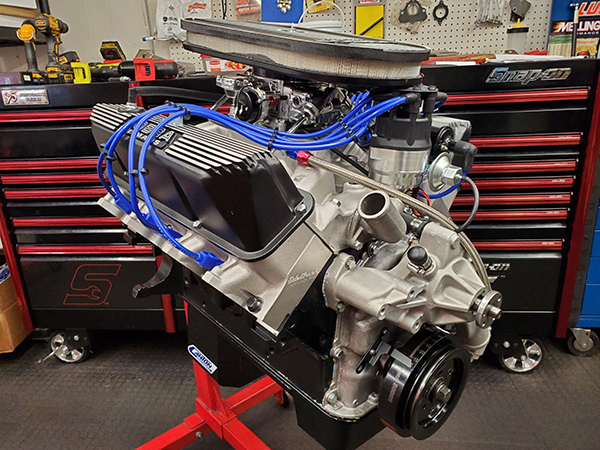

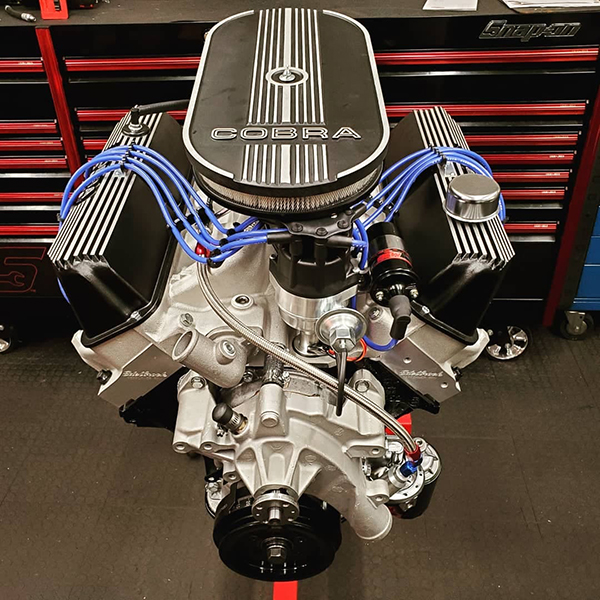

“The customer is actually up in Canada, but he contacted us looking to get 450 horsepower, so we did a 390 FE engine,” he says. “We put together a 390 with a custom COMP roller camshaft, Edelbrock aluminum cylinder heads, Harland Sharp rockers, a Performer RPM intake, a Quick Fuel carburetor, custom-length Smith Brothers pushrods, ARP hardware, Clevite P bearings, a stock crankshaft that was ground and reconditioned, forged Speed Pro pistons, factory, reconditioned connecting rods, a Canton Racing rear sump oil pan, and a high-volume oil pump.

“We did all the machine work in-house on our CNC and set all internal bearing clearances, etc. The block went through the standard machining processes, but we did have to restrict the oil up top, which is a common thing for the FEs. Other than that, it was a pretty straight forward build.”

The customer’s ’76 F-150 is lifted and sits on 38-inch tires. Now, it adds a 420 horsepower 390 FE engine with 515 ft.-lbs. of torque! Giddy up!

Engine Builder magazine’s Engine of the Week eNewsletter is sponsored by PennGrade Motor Oil and Elring – Das Original.