Article courtesy ENGINE BUILDER.

Like many folks who make engine building a career, Tim Richardson found an affinity for diesel when he was in high school. He had a ‘91 Dodge truck that he swapped a Perkins diesel engine into. He found an adapter plate to bolt the Perkins to the transmission in his Dodge, and despite the power level not being quite what he wanted, Tim was hooked.

“The Perkins didn’t have the power or the performance ability I was really after, so a few years later I bought a Cummins first Gen and started working on it and my passion for diesel evolved out of that,” Richardson says. “People saw that I was working on mine and they started bringing me theirs and the next thing you know I’m really busy with diesel work. I worked two years in the diesel injection industry. I learned the diesel injection side of the 12-valve and primarily Cummins engines. Then, I started my shop in 2009, building high-performance engines for other people.”

That shop is called Richardson Diesel, located in Bidwell, OH. Tim runs the shop along with help from his two sons, and does everything in-house for 12-valve and 24-valve Cummins engines. The shop builds its own injectors, pumps, turbochargers, engines, and more.

“I’m really hands on with it,” Richardson says. “That’s the reason I’ve stayed primarily with the 12-valves is because I don’t have to outsource tuning and all that other stuff. I do 24-valve and 12-valve Cummins engine work. I do some electronic stuff, but I really like the mechanical platform.”

One such example is Tim’s own 2.6 Smooth bore 5.9L Cummins engine in his shop truck – that ‘91 Dodge. This particular engine had previously been built to run in the Brush Pulling open class with 1,500 horsepower on hand. However, as COVID has affected many things, pulling events included, Tim says he’s had a tough time finding pulls to compete in. His solution was to move to the sanctioned competition of the 2.6 class.

“The problem we’re having trouble with right now is finding pulls with COVID because county fairs are not investing the money into pulling,” he says. “Switching to the 2.6 platform, I’m finding pulls that I can go to. That’s the main reason for the rebuild. We scaled it back to run the 2.6 because that’s a sanctioned pulling class and it’s getting hard to find pulls otherwise.”

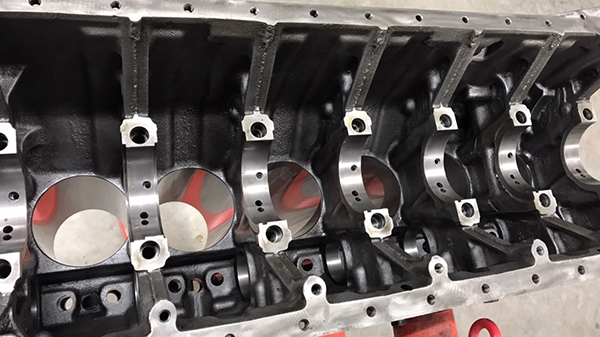

Richardson says he built this engine with a few upgrades to fit the different rules of the 2.6 class, and started the build with a ‘95 Cummins 12-valve block.

“The block has been line bored and it’s got cam bearings in it and the block is filled with hard block,” he says. “The crank is still an OEM polished Cummins crank. Nothing has been done to it other than it’s been balanced, polished, I added oil clearance to it, and it has Haisley Clevite H-series coated bearings. It’s got a set of Apex Diesel billet rods in it. I’ve worked with Haisley (Machine) for years, so it’s got a lot of Haisley parts in it.

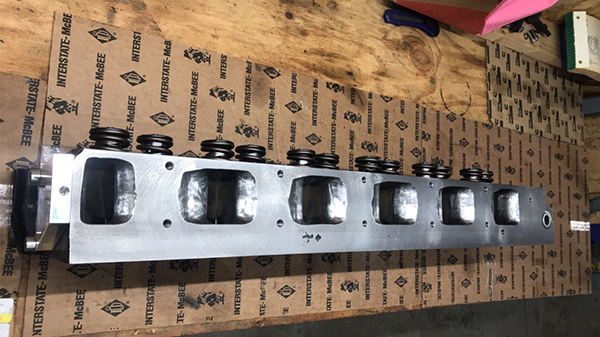

“The engine is still a standard bore 5.9L Cummins. It’s got Haisley studs and a Haisley girdle in the bottom end of it, and it’s got a set of custom Haisley spec Ross Racing pistons. In addition, it has a Hamilton billet steel camshaft and a Hamilton cylinder head that was ported by me and a good friend of mine. We ported the head and did all the valvetrain work.”

Speaking of the valvetrain, Richardson utilized a set of PBM valve springs for a big block gas application, but machined the head to accept them. It also has Hamilton oversized valves, Manton tool steel pushrods, Hamilton billet tappets, and the injection pump is a Farrell Stage 6 13mm injection pump.

“For the injectors, those are a different combination,” he says. “They are a Harts diesel billet body with a nozzle that I designed. I found some more power in my nozzle. I’ve built a lot of injectors with the 12-valve and have really learned a lot over 15-18 years with the 12-valve power.

“The engine also has Haisley Machine L19 head studs. It has a Haisley Machine billet front cover. We’re still utilizing the stock rockers because I’ve had good luck with them. It also has a Fluidampr and it runs a Valair triple-disc clutch on the back of it.”

As of now, the engine is still waiting on a turbocharger before it’s completed, but Richardson hinted that it would likely be an Apex turbo. As for the truck itself, it’s a 2001 chassis that’s been completely braced and fabbed for pulling on top of a ‘91 Dodge body.

“It’s the original truck I started with,” Richardson says. “I’m putting that body on the late chassis. It’s a full one-off build for pulling.”

This one off build, with some changes to make it 2.6 legal, will be shooting for 1,100 horsepower when it’s all said and done.

Diesel of the Week is sponsored by AMSOIL.