As a racer growing up in motorsports, I’ve raced all kinds of set ups, from supercharged engines with mechanical fuel injection to carbureted engines and even EFI. In fact, I was one of the first to run EFI on my Super Comp dragster 10-15 years ago. Being one of the first, there was a lot of trial and error that went into getting the set up just right. There was also a lot of tuning that went into each pass. I found myself wanting to race more than tune, so after a few years, when I didn’t find the significant advantages in consistency and horsepower gains with EFI, I went back to what I knew worked – carburetors.

In fact, that realization led me to found Get’M Garage with my business partner Mike Laws, in 2017. Get’M Garage supplies carburetors, carburetor kits and specialty parts to carburetor modifiers and engine builders in the specialized racing industry.

Now, I can already hear what you’re thinking… ‘hasn’t electronic fuel injection taken over the market?’ It’s true that EFI has come on strong in racing over the course of the past 10 years. Even electric-powered race vehicles are starting to make in-roads into mainstream forms of racing. All of which certainly begs the question – are carburetors still relevant in motorsports? The answer – without a doubt!

The premise behind how a carburetor works hasn’t changed since Samuel Morey first invented it nearly 200 years ago. It was a calibrated leaker then and it’s a calibrated leaker today. What makes a carburetor relevant today is much different than in Mr. Morey’s era or even 60 years ago when carburetors really took hold of the racing scene.

Today’s high-performance racing engines are all about how much horsepower we can squeeze out of a combination. Foundries like Dart and Brodix are producing precision engine blocks from better, stronger and lighter material. Camshaft technology has improved for better airflow. CNC head porting and CNC intake porting optimizes air and fuel flow, which increases horsepower.

At the same time, we have seen significant gains in fuel technology. What started with 97 and 110 octanes has now given way to methanol fuel and more horsepower-driven fuels like Q16, which is an oxygenated fuel, and M5, a methanol-nitro blend. On the downside, these fuels tend to be less forgiving and more corrosive to cast aluminum pieces.

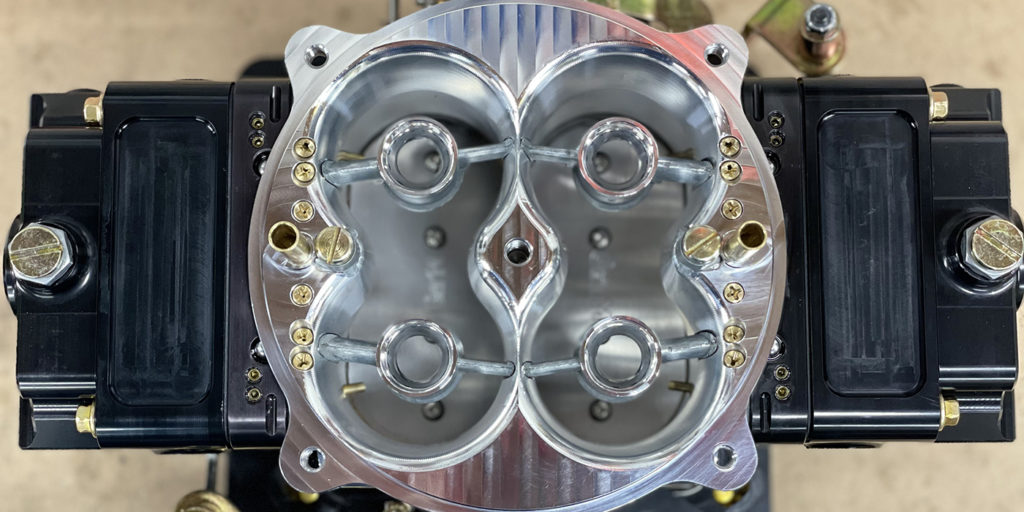

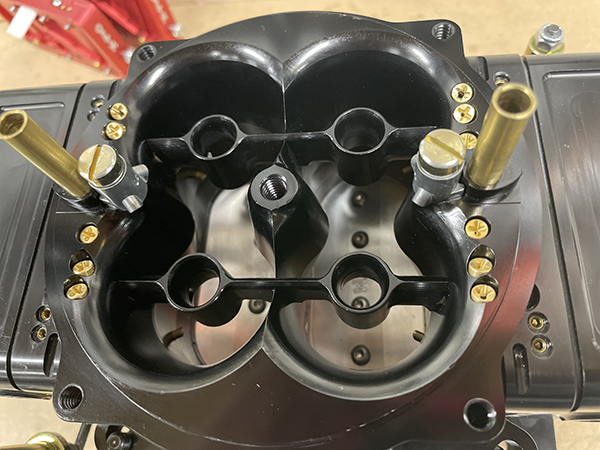

Where does that leave the carburetor? Quite simply, carburetors have been forced to evolve in order to remain relevant as engine builders continue to push the limits on horsepower. With all of these innovations in critical engine components, it’s only natural to CNC port aluminum carburetor components like billet main bodies, billet fuel bowls and billet metering blocks to match the engine build. This has given rise to truly custom carburetors to compliment these custom engines.

Think about all the decisions that go into building a high-performance motor: cubic inch, compression ratio, cam design, crankshaft, target horsepower, fuel, etc. And let’s not forget racing application and even track length. These same factors go into designing and building a custom billet carburetor to work in concert with that engine combination to make it most efficient and consistent. You just can’t pull a mass-produced cast carburetor with a generic tune off the shelf and expect optimal performance out of the box. The right carburetor correctly paired with an engine combination should result in increased horsepower and consistency, which translates to lower ETs and higher MPH.

The technology that goes into building a carburetor has modernized it for today’s demanding racing applications. Thanks to advances in CNC capabilities, the options are virtually limitless. With 5- and 6-axis CNC capabilities, we can literally machine anything we want to build out of a chunk of billet aluminum. We don’t have to wait for a large company to build something for us and then modify it.

With the advent of 3D printing and its continued development, we can use that technology to design a part, 3D print it, make any adjustments, test it and perfect it before ever moving to the CNC machine for production. All of that versatility has really opened carburetor innovation.

Most engine builders utilize a dyno to maximize an engine’s performance before it ever leaves their shop. Traditionally, dyno carburetor tuning has involved jet and air bleed adjustments. Now, we can alter the carburetor’s CFM on the spot by changing out removable boosters. So what makes the carburetor the go-to choice for so many racers?

First, carburetors just work. With their simple, straightforward, mechanical design, carburetors simply work. They are easy to install, easy to adjust and don’t require fancy electronics or hard-to-understand wiring diagrams to decipher. Generally speaking, it’s as easy as bolting the carburetor on, hooking up the fuel lines and firing up the engine. Plus, any necessary adjustments at the track can be made with simple tools.

Second, carburetors are capable of building as much, if not more, power than EFI. This can depend on the application and the rpm band, but carburetors are no slouch when it comes to power production.

The third thing that makes carburetors so great is fuel curve management. Today, we can manipulate fuel curves as effectively as EFI with jet and air bleed changes. No special computer program with preset or specialized tunes to have to choose from. With 3, 4 and even 5-circuit carburetors, and a simple OS reading, we can maximize the fuel curve to what the engine is needing for optimal performance.

Finally, for many racers it comes down to pure economics. A carburetor system is generally less expensive than its EFI counterpart with a different fuel pump, fuel tank and all the various sensors. In the end, you may have a $10,000 EFI commitment with no performance advantage compared to a $1,500-$2,000 carburetor.

When you look at today’s drag racers, truck pullers, circle track racers, dirt track racers, and even offshore boat racers, a vast majority of them run carburetors. Regardless of which forms of motorsports you are involved in, most sanctioning bodies have classes that either require carburetors or allow carburetors.

Specialized classes are popping up within big name series and big name races. For instance, the Motor City Muscle Challenge featured at several of last year’s NMCA races, is a heads up, naturally aspirated class running on 9-inch tires using a 4150 carburetor with a cubic inch rule and weight rule. The class is designed to challenge the engine builder, driver and suspension tuner to do “more with less” with cars running in the 8-second range in the 1/4-mile. Dave Burke and Shawn Stanisczewski are just a couple of drag racers dominating this class.

Then, there’s the maximum horsepower seekers – grudge racers and bracket racers seeking single and dual carburetor set ups – including blow through carburetors and nitrous combinations for their large horsepower, big cubic inch engine combinations. Just 10 years ago, a 7.00-second Top Dragster would qualify in the game. In today’s Top Dragster fields, a 6.20 pass may not get you in the field. Bracket racer Tim Honeycutt runs in the 4.20s in the 1/8-mile on a single carburetor, naturally aspirated set up, and NHRA Top Sportsman racer Chip Rumis regularly runs 6.20s in the 1/4-mile with his blow through carburetor combination.

It all boils down to one simple fact – racers want to race. As long as carburetor technology continues to innovate and keep pace with advancements in other key engine components, the carburetor will remain a viable option for racers and engine builders alike.