When we searched for information about oil leaks in Toyota’s 2GR-FE engine, we found hundreds of complaints in a few mouse clicks. The V6, found since 2004 in many of the company’s flagship vehicles including Lexus, was a replacement for the celebrated 2JZ inline-six. Toyota continues to use this engine in various applications with minor updates to the design to this day.

The GR engine features an open-deck, 60° aluminum block and aluminum DOHC cylinder heads. The 2GR has 4-valves per cylinder and dual variable valve timing (VVT-i). Some versions use multi-port fuel injection, while others use direct injection or a combination of direct injection and multi-port fuel injection.

The 2GR-FE is transversely mounted in FWD applications such as the Camry and Avalon. This can be pose a challenge when dealing with oiling issues from the timing cover and VVT-i supply line, which has been under a recall due to failures in the rubber hose.

The condition results in the rubber portion of the oil supply hose for the VVT-i actuator degrading over time. This condition may cause an oil leak from the VVT-i oil supply hose producing abnormal engine noise and the oil pressure light to come on. The problem stems from the rubber portion of the engine oil supply hose for the VVT-i actuator that may develop a pinhole leak. Over time, exposure to small amounts of corrosive gases from the positive crankcase ventilation (PCV) may cause this pinhole to expand. As a result, the oil may leak from the hose. In some cases, the leak may cause abnormal engine noise or the oil pressure light to come on, but not always.

Many vehicle owners have experienced a sudden loss of oil when the rubber hose ruptures, spewing most of the crankcase oil on the underside of the body. Some owners have noted that oil is only present on one side of the undercarriage, which typically is in-line with the oil supply line from the crankcase to the VVT-i. In response to the oil leaks, Toyota has extended its Limited Service Campaign (LSC) 90K for vehicles that were not repaired before the expiration of the original LSC (issued in 2014). This LSC extension covers approximately 117,500 vehicles.

The original recall used a replacement hose that was made of an upgraded rubber, but it too had failures, according to reports we found. Toyota dealers were supposed to mark the replacement hose with a yellow tag if it was repaired, but if the hose is not the full metal replacement tube that is used on premium Lexus vehicles, the part may fail again. In this case, we are not sure if Toyota will cover the part if it has been replaced before. The LSC is good until December 31, 2021, according to a Toyota Bulletin.

While the VVT-i supply line may have some limited warranty coverage, there may be other 2GR variants that are affected by similar leaks that are not covered. Other common leaks found on these engines stem from the front timing cover seal breaking down. Some TSBs indicate that the 2006 model year vehicles such as the Lexus IS350 may develop a small oil leak, located on the timing cover and the camshaft housing sub-assembly. In these applications, the repair involves removing the engine to fix the seal. To gain access to the timing cover and to replace both camshaft housing sub-assemblies, the engine must be removed and new gasket material, timing cover seal and cover bolts installed. While the repair seems extreme, these issues are not as common as the LSC.

The Lexus repair highlights a worst-case scenario, but bear in mind, most of these small oil leaks can be repaired without removing the engine on applications that are longitudinally mounted or allow access to the timing cover. If the leak is located where the Bank 1-cylinder head, engine block and timing cover meet, you must use an oil dye to confirm the source of the oil leak. Then remove and reseal the timing cover if confirmed leaking exists.

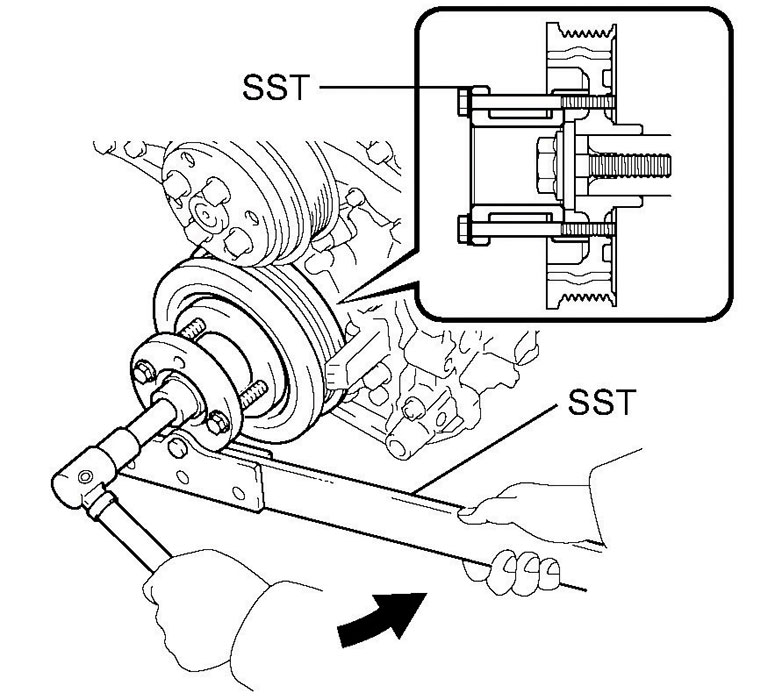

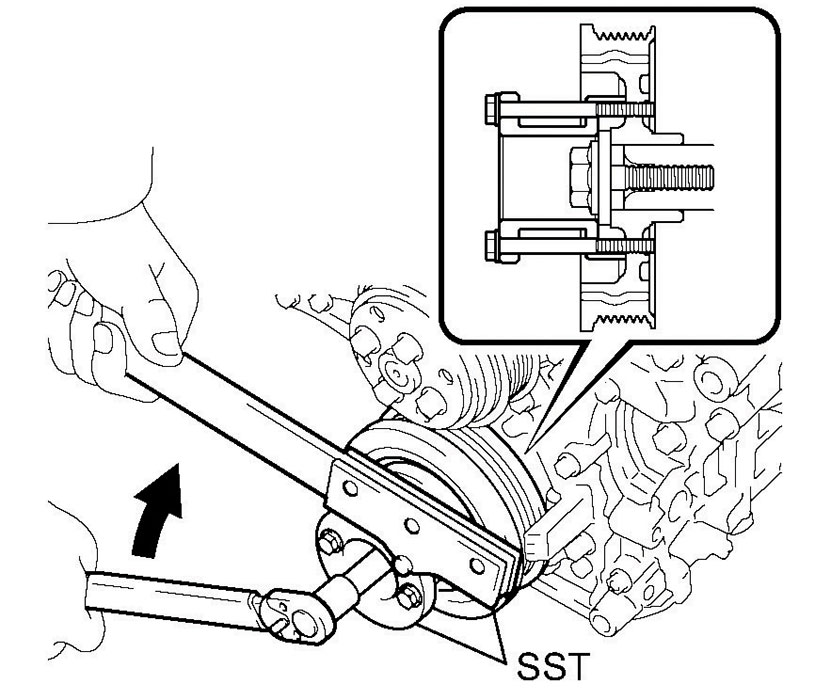

Use a crankshaft pulley holding tool (SST 09950-50013) to loosen the pulley bolt and remove the pulley. To remove the timing chain oil seal, use a screwdriver with a taped tip to pry out the oil seal. After the removal, check the crankshaft for damage. If there is any damage, you can typically smooth the surface with 400-grit sandpaper.

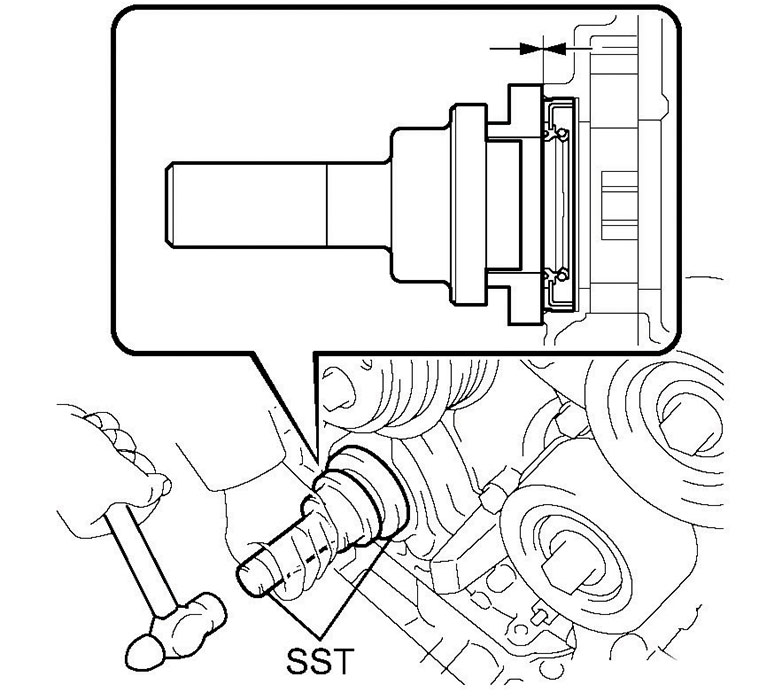

Next, use the crank pulley holder and a hammer to tap in the oil seal until its surface is flush with the rear oil seal retainer edge. Keep the lip free of any debris, and do not tap the oil seal at an angle. Then install the pulley set key to the key groove and align the pulley set key with the key slot of the pulley, and slide on the pulley. Using SST, install the crankshaft pulley bolt and torque to 184 ft.lbs and install the ribbed V-belt and radiator. Run engine and check for oil leaks.

Besides the 117,000 Toyota applications affected, there are about 50,000 Lexus models (RX350 and ES350) covered by the warranty for the VVT-i supply line. It should always be made of metal and not include any rubber parts. There are also reports that some 2007-’08 Sienna’s equipped with the towing package and oil coolers, that the oil cooler line is made of the same type of rubber hose as the VVT-i line. These may be a trouble spot to keep an eye on for suspected leaks.

This article courtesy of ImportCar.