The N54 was a leap forward for BMW. It wasn’t the first turbocharged engine produced by the German automaker, but it certainly set the bar high. In fact, this engine was so well received by critics and enthusiasts, it’s been called “the German 2JZ.” Comparing the N54 to the iconic 2JZ engine in the Toyota Supra shows how highly regarded it has been since its introduction.

However, as with all mass-produced engines, there are some common issues which will be faced by the vehicle owners. Here are some common problems or failures that you should be on the lookout for:

#1: Turbocharger Failure

We’re going to start our list with turbo failure, even though this isn’t the most common issue for these engines. The turbos live a hard life. The turbine and the compressor can spin up to 200,000 rpm, and the exhaust inlet temperature can reach up to 1050° C. The turbos are built to withstand these conditions, but they will eventually wear out over time.

Symptoms of a faulty turbocharger may include loss of power, abnormal whistling noises, excessive smoke from the exhaust, high fuel consumption, overheating, high exhaust temperature, and oil leaks from the turbo. But, it’s important to note that defects in other components can produce the same symptoms. Before condemning the turbocharger, remember that turbo performance can only be impaired by mechanical damage or blockage caused by debris.

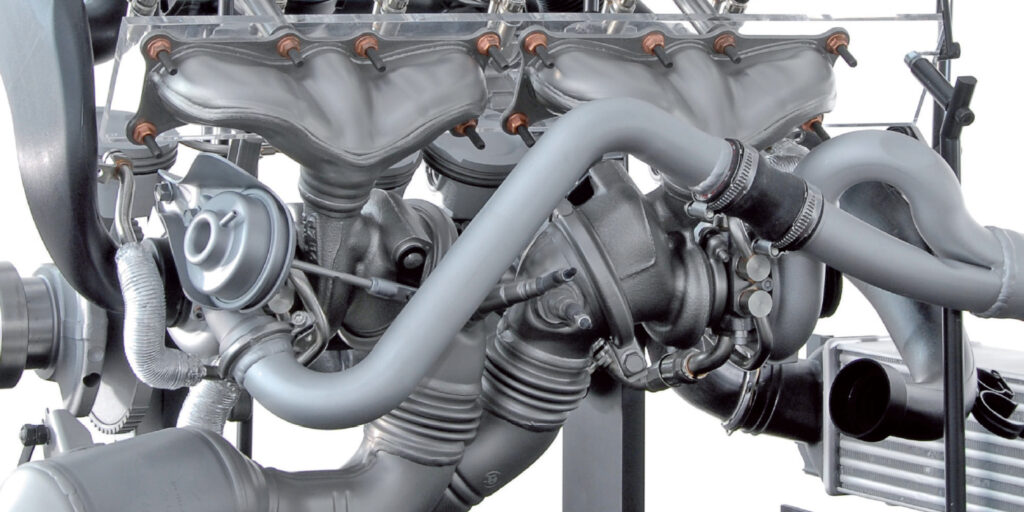

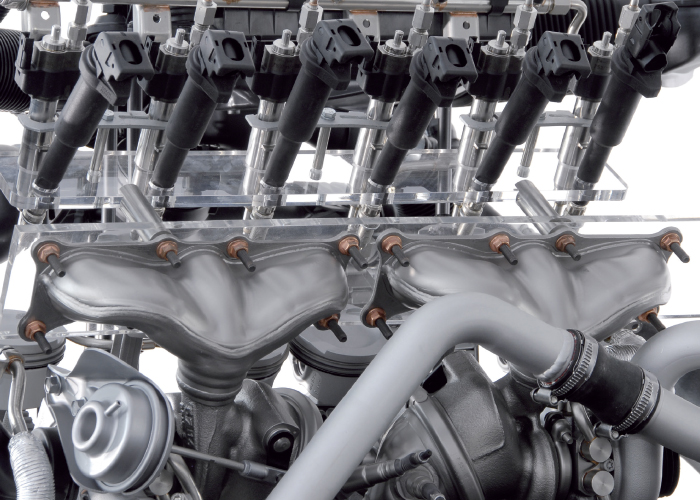

So, what can cause a turbocharger to fail prematurely? The vast majority of turbo failures are caused by oil starvation or oil contamination. The N54 turbos are supplied with engine oil and coolant to keep their high temperatures in check (Figure 1). These two fluids are the literal lifeblood for the turbos, and if either one is restricted it can quickly spell disaster. In some cases, the turbo may fail due to damage from the introduction of foreign debris.

If you are replacing a failed turbocharger, there is a chance that debris was carried through the intake system. Best practice would be to inspect and clean out all affected components in the system. If metal debris has lodged itself in the intercooler or intake manifold, it could work its way into the engine later on and cause more damage. It’s also a good idea to replace the turbocharger coolant and oil lines as well. If the hoses or lines are damaged, clogged, contaminated, or faulty they can lead to premature turbocharger failure. Some oil feed lines may contain screens or filters inside them, which could trap metal debris and lead to oil starvation.

#2: Boost Leaks

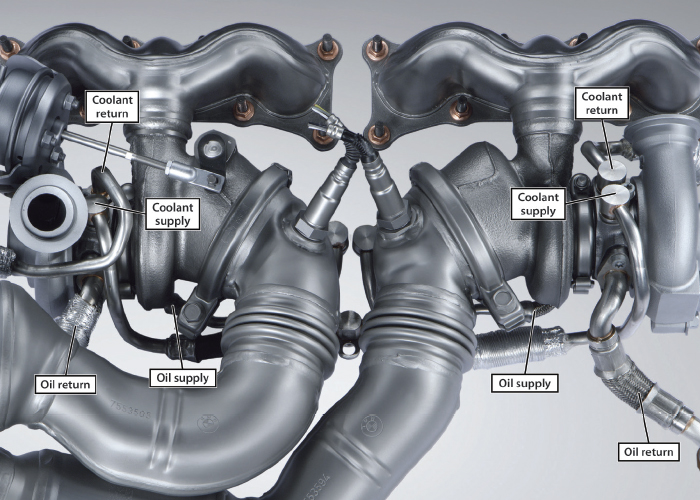

Boost leaks are the Achilles heel of turbocharged engines. Turbos work hard to build boost pressure (AKA charge air) and add power, but the smallest pinhole or a single loose clamp can undo it all. A system of pipes, hoses and couplers are needed to carry charge air from the turbocharger, through the intercooler and into the intake manifold. The N54 has a particularly complex system of plumbing to manage all of this charge air (Figure 2).

When searching for the source of a boost leak, start with a thorough visual inspection of the pipes and hoses, with the engine OFF, of course. A ruptured hose may appear to be intact, so squeeze, pull and twist them as needed to locate the source of the leak. Look for evidence of rubbing or contact between the pipes or hoses and neighboring components. Look for any clamps which may have worked their way loose, or were improperly installed during a previous repair. Vehicles with tuned ECUs will run higher boost pressures than stock, and this can also highlight weak points in the plumbing system.

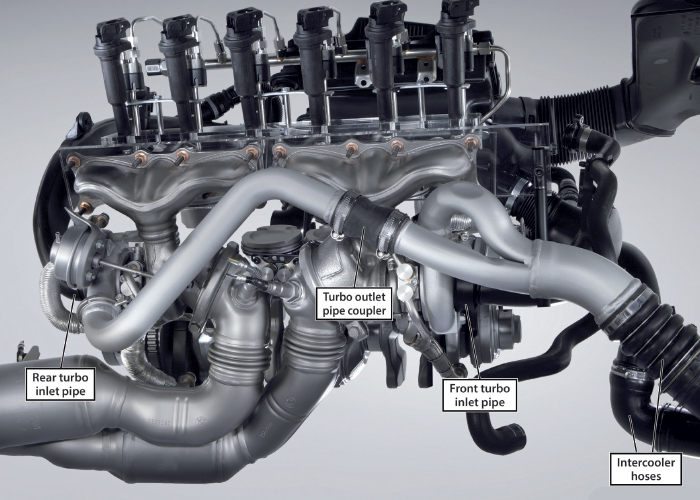

The turbo inlet pipes are particularly difficult to service. These pipes wrap around the front and rear of the engine, and are molded to fit into the tight engine bay. They were clearly installed onto the engine on the assembly line before the engine was placed into the vehicle. The rear turbo inlet in particular cannot be removed from the engine bay in one piece, but the rubber seals between the inlet pipes and the turbo snouts are serviceable (Figure 3).

The intercooler is vulnerable to damage due to its location down low in the radiator support. It is exposed to fresh air coming through the bumper cover, but this also means that the fins can be damaged by rocks and other road debris. The end tanks are plastic, and can become brittle after years of heat-cycling. Be sure to closely inspect the intercooler, as well as the hoses and pipes which connect it to the rest of the system for any signs of damage or wear.

#3: Wastegate Rattle, Vacuum Supply Issues

The next most common issue found by N54 owners would be wastegate rattle. The engine-management system uses vacuum-controlled wastegate valves to control the boost pressure based on engine speed and load. Once boost pressure has reached its desired level, the wastegate valve will begin to open. This directs part of the exhaust-gas flow past the turbine wheel, preventing the compressor speed from increasing.

Your customer may state that they hear a slight rattle noise, similar to that of a mechanical typewriter, coming from the engine compartment after they’ve turned off the engine. They may also complain of a slight reduction of power, similar to an increased turbo lag. There are a number of possible causes for this issue, but the most common, and easiest to find would be restricted, kinked, or blocked vacuum supply hoses.

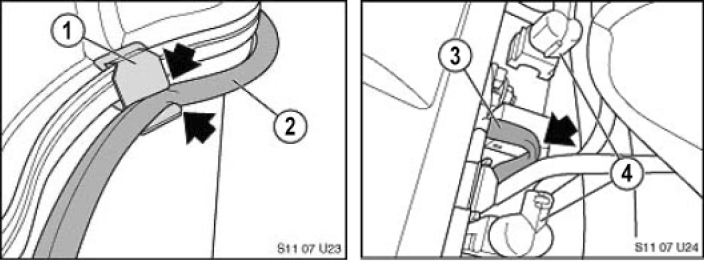

This example comes from TSB SI B11 14 07, where BMW outlines a few common scenarios where the vacuum hoses can kink. The vacuum hose (#2 in Figure 4) could be improperly secured in a mounting clip (#1 in Figure 4). Or the vacuum hose (#3 in Figure 4) can kink if it is bent too sharply. This could prevent the wastegate vacuum solenoids (#4 in Figure 4) from receiving the proper volume. Even if the hose is only slightly collapsed, it could cause intermittent boost faults. Replace the vacuum hose if you have any doubt at all about its condition, and be sure to reroute it so that it is free of kinks or restrictions.

Don’t be fooled by the adjustable end link on the wastegate actuator (Figure 5). The adjustment procedure for the wastegate actuator is lengthy and complex, requiring the use of an IMIB scan tool or equivalent. Some may be fooled into thinking that adjusting the end link is a “quick fix” for boost issues, but this is simply not the case. For more information on this procedure, reference TSB SI B11 04 10.

#4: Installer Error

Let’s wrap up this list by talking about installer error. We’ve all seen vehicles come into our bays with issues that were caused by previous work. It could be a customer who earned a degree from YouTube University and thought that they could handle the job, or it might have been a tech who wasn’t familiar with that particular vehicle or engine. Regardless of who was in there before you, you may inherit a repair which was made more difficult by someone before you.

This is one of the reasons why it’s so important to reference the OEM service information. You may be unaware of certain service considerations such as torque specifications, break-in procedures, etc. A good example of that is the copper nuts which secure the turbocharger to the cylinder head (Figure 6). These nuts will be one of two diameters: M7 or M8. Both size nuts need to be torqued to 20 Nm, and you should always replace them once they’ve been removed. However, CRC copper paste must be applied to M8 threads only, M7 must be installed dry. Failing to torque these nuts properly will cause them to work their way loose, leading to a noticeable exhaust leak and a customer comeback.

Another example of installer error would be failing to properly clean gasket surfaces, replacing gaskets during service, or failing to clear out debris from a previous failure. This example comes from TSB SI B11 07 11, where BMW outlines how a restricted oil supply line can lead to oil starvation and turbocharger failure. You should always clean the area where the engine oil supply and return lines connect to the engine crankcase. Be sure to prevent any debris from entering the engine oil or crankcase. Oil contamination can lead to additional engine damage.

Always remove and inspect the engine oil supply and return lines for blockage or restriction, or replace them entirely. Always replace the crush seals on banjo-bolt connections.