Another article on A/C equipment? Has it really changed that much? The truth is, we’ve got it pretty good these days as technicians. In the world of A/C service, the names may remain the same — manifold gauges, leak detector, recovery/recycling machine, vacuum pump, fluorescent dye and an ultraviolet (UV) light — but the reality is the tools, equipment and techniques have improved drastically over recent decades.

Sure, a lot of automotive equipment has improved, but A/C service might stand alone with some good stories to tell.

Back when R-12 was the charge that kept our cars cool, electronic leak detector technology was not well refined and dye was not yet utilized. The most common way to check for a leak was through the use of a propane leak detector, as it was called, because it used a bottle of propane. It worked by drawing air through a tube, which led to a copper element being heated by the flame from the burning propane.

To use it, a technician would hold the pickup tube near any areas of an A/C system where they suspected a leak. As they moved the tube around the system, they would keep an eye on the flame. If the flame burned blue, there were no leaks. However if R-12 was present, when it passed through the flame and over the heated copper element, a chemical reaction took place and the color of the flame turned to bright green.

So when the flame turned green, you found your leak. It was a very accurate method of finding leaks, but another chemical reaction took place also, one that produced phosgene gas. If you know the name, you know what it is. If you’re not familiar with phosgene gas, it is extremely poisonous and it was used as a chemical weapon during World War I. During the war, it was responsible for approximately 85,000 deaths.

Now, did this ever actually hurt a technician? The concentration of gas was ultimately very low, and I’ve never heard of anyone being harmed, so probably not, but it does make an interesting story.

So what do today’s tool companies have to make A/C diagnosis and repair a much easier (and safer) process? Let’s get into it.

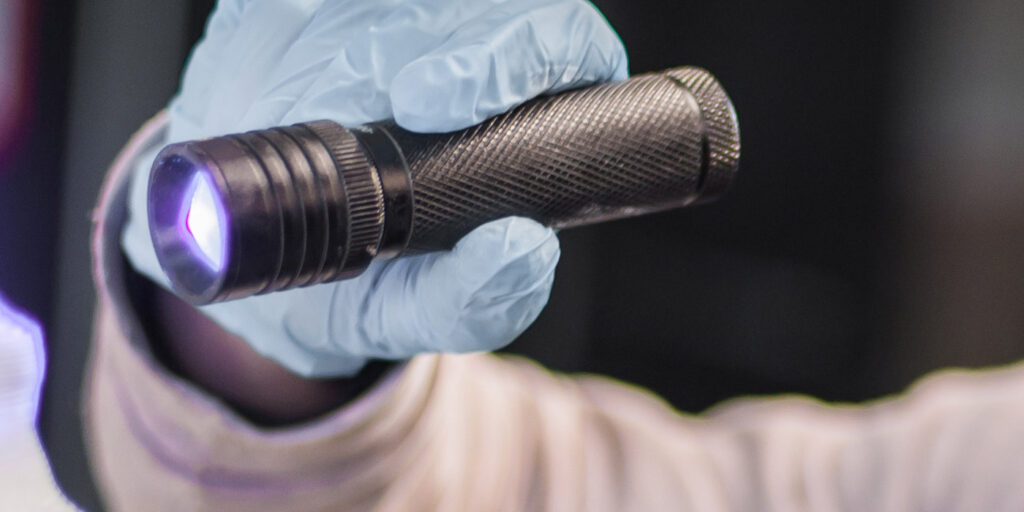

A/C Dye and Ultraviolet Lights

Most of us are familiar with A/C dye. The bottom line is, it’s a great way to find a leak. Many A/C charging machines inject it automatically, but there’s also a common need to do it by hand. The traditional caulking-gun style of injector works well, but one of my favorites in this category is the metered style of dye injector. They are designed so one squeeze of the trigger (and I might mention they’re a lot easier to squeeze) injects the exact amount of dye needed — no watching the lines on the tube.

Ultraviolet lights have long been getting smaller and smaller and benefit from modern battery and LED technology. They come as small as a standard penlight and still offer the full spectrum of light for UV leak detection. A favorite in this category is a standard white LED work light with a built-in UV spotlight so you’ve always got the light you need on hand during an inspection.

Manifold Gauges

Who doesn’t appreciate a good set of manifold gauges? Even though a standard part of A/C charging machines, sometimes the machine is being used and you don’t have time to wait. Or you might be doing an inspection off-site. For those who like the newest technology, a set of digital manifold gauges just might be the ticket. They are pretty tricked out with easy-to-read LCD displays and features such as refrigerant and oil capacities.

Flush Equipment

Designed to flush evaporators, condensers and A/C lines, while this equipment is fairly basic and hasn’t really changed much, it’s an important part of the job. Even though there’s not much to say about the equipment itself, there’s always room to talk about condensers and the importance of servicing them.

The efficiency of a condenser in terms of heat transfer is critical to A/C operation. If the refrigerant in a system is not completely condensed (changed from a gas to a liquid state) while it passes through the condenser, then the system will not cool as it should.

The two types of condensers in modern vehicles are the serpentine and the parallel flow condenser.

A serpentine type of condenser can easily be identified by one long tube that goes back and forth side-to-side and resembles, well, you guessed it. The refrigerant only has one path to flow and these condensers can be easily flushed and reused.

A parallel flow condenser has multiple paths for refrigerant to flow and is easily identified by the thin, flat tubes that run side-by-side. These are very efficient and work excellent, but the drawback is they cannot be flushed. If you suspect contamination or even slight blockage in one, it should be replaced.

Condenser Tools

The little extras such as fin straightening tools and blow guns designed to reach down in between a radiator and compressor to thoroughly blow them out can make just enough difference in condenser efficiency to make the end performance of the A/C systems you work on stand out amongst the crowd. Another bonus to this attention to detail is that the more you can offer your customers and document what you have done to their car, the more they will realize the value in the work you have done.

A/C Clutch Removal Tools

These also fall into the category of not too much new, but they are always worth a mention because when you need one, you need one. They turn clutch removal and installation from nightmare to dream and are well deserving of real estate in your toolbox.

Electronic Leak Detectors

Traditionally known for their hit-or-miss qualities, it’s been easy to be frustrated with these in the past. Thanks to modern electronics, a good name brand will give you good results. Many models feature automatic or manual calibration as well as adjustable sensitivity. They can pick up extremely low levels of refrigerant and some models feature built-in LED UV lighting — talk about cool!

A/C Machine

Modern recycling and recharging equipment benefits from the latest computer technology just like your cell phones or any new electronics. They continuously get better and better. Touchscreens are becoming the standard with graphic interfaces that make them easy to see and use.

Fully automatic operation is one of the nicer features and it is a huge timesaver. With the push of a button, the machine will go through a complete evacuation and charging cycle, freeing you up to get other stuff done while the machine does its work. Manual operation is always an option for those situations where you need it.

Automatic oil and dye injection is available on a number of machines and while not entirely necessary, especially if you already have the tools, it’s another great timesaving feature with less mess. Tank heaters are also commonplace, which makes the charging function go a lot quicker.

Where you really begin to benefit is in the database that is stored in most modern machines. You can quickly and easily look up refrigerant and oil capacities for any vehicle. Many new machines will also store vehicle information linked to a license plate so you can also look up past service that has been done.

Many machines have a built-in printer, which can benefit the conversation with your customer. Providing them with a printout directly from the machine documenting the amount of refrigerant recovered and recharged gives them an increased sense of trust and accuracy with your work.

The bottom line is modern equipment offers everything you need to perform A/C work efficiently and accurately, and to represent the quality of your work to your customer. It’s a true investment in your future.

This article courtesy of TechShop.