Air ride systems can control vehicle ride height, passenger comfort and improve handling. How they operate and work with the rest of the systems on the vehicle is part of the embedded logic of their control system.

There are three main edicts written in this programming: preserve the compressor, keep the vehicle level and keep the vehicle safe.

SAVE THE COMPRESSOR,

SAVE THE SYSTEM,

SAVE THE DRIVER

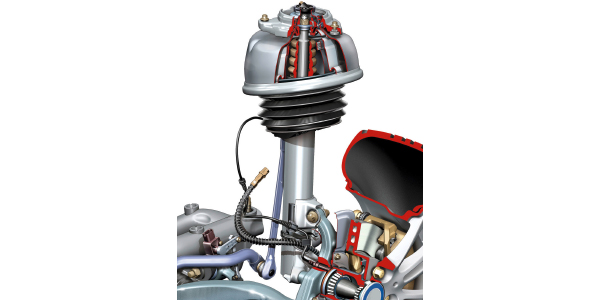

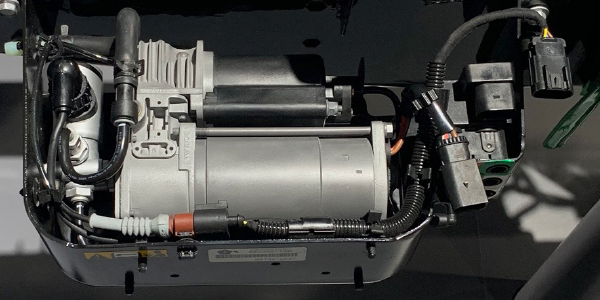

One job the system’s embedded logic can perform is saving the compressor from destroying itself. If a system has a leak, the compressor will have to work harder to keep the vehicle at the same ride height. And, when the compressor has to work for longer periods of time, it will get hotter. Excess heat can cause premature wear of the piston rings, and, if the leak goes unchecked, it can cause the compressor to fail completely. When the pump fails, oil and metal debris can enter into the valves, reservoirs and bladders.

Most pumps do not have a thermocouple to measure its exact temperature. The computer module controlling the pump keeps track of how long the compressor has run and how long the correction should take. If a correction to ride height takes too long, the system knows that the compressor could overheat, so it canset a code and disable the pump before it’s damaged.

Almost every air ride vehicle has a self-diagnostic process that occurs during startup. On some vehicles, if the self-check detects a problem, it will disable the system or put it in a fail-safe mode and alert the driver. It will also set a soft or pending “C” or chassis trouble code.

The check does a bias voltage check to the valves and sensors circuits have integrity. This is a quick voltage signal applied to the circuit that needs to come back within a specific range. If a solenoid has a damaged coil, the decreased or increased resistance will cause a code.

Some systems will do a quick actuation of the suspension to see if the solenoids and valves are functioning. The module will also look at the pressure in the reservoir or compressor run time to verify system integrity.

VEHICLE LEVELING LOGIC

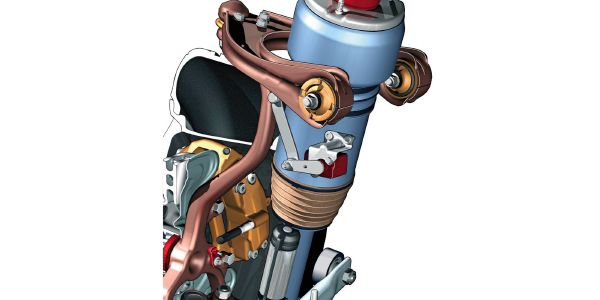

When the air ride system detects a substantial change in position due to a load, its preprogrammed logic makes the right correction by taking into account the vehicle’s key position, amount of movement and other information.

If the key is off, some systems may wait 10 seconds before making a correction, while some may wait until the vehicle is started. Most systems will limit compressor run time with the key off to preserve the battery. If the vehicle is running, corrections to the ride height are smaller and more targeted at tuning vehicle attitude.

KEEP THE VEHICLE SAFE

Most intelligent air ride systems use information from the ABS and electronic stability control (ESC) system, like vehicle speed, yaw and driver inputs. If there is a problem with the air ride system, the vehicle knows the lack of body control will impact stability.

Late-model air ride systems are on the serial data bus. They can use different inputs from other systems to determine the correct position of the suspension, which can include vehicle speed, engine load and other PIDs. Likewise, the air ride module shares data with the other modules on the serial data bus. A simple failure of a door switch can prevent the system from working on some vehicles.

Rather than letting the vehicle rest on the bump stops with the compressor running non-stop, the air ride system will disable or set the suspension at a safe pressure. The vehicle will then alert the driver with an instrument panel warning. Some air ride systems even limit the speed of the vehicle until the problem is resolved.

As highlighted earlier, most vehicles equipped with air ride systems can self-diagnose problems within the system during the startup process Depending on the vehicle, this can include checking sensor inputs, valve actuation tests and pressure checks and, in some caes, notification of the driver, disabling of the system or putting it in a fail-safe mode.

On some ESC systems, the ESC module has the ability to store DTCs as current or history codes. The system uses an ignition-cycling diagnostic approach in order to reduce the occurrence of false or intermittent DTCs that do not affect the functionality of the system. This allows for the “fail-soft” actions to be taken whenever a malfunction condition is current, but requires the malfunction to be current for a certain number of ignition cycles before the corresponding malfunction code and message is stored or displayed. This is why some customers will say they started the car again and the problem was gone.

INFORMATION IS KEY

The key to understanding the embedded logic of air ride systems is using service information for help. For most vehicles, the air ride logic is included in the “system description and operation” section of the service information. Some OEMs include diagnostic tests in the service information that can pinpoint faults.

Some OEMs also have released new calibrations and programs that can be reflashed onto the control module. These programs can help to eliminate excessive key-off power drains and improve the logic of the air ride system.