Google spray guns and you’ll realize we have it pretty easy today, application-wise. What may escape your thoughts are the liquid developments which were necessary to successfully harness the production potential of the spray gun. Of course, the solution to one problem always creates a new problem. I say “problem,” but “challenge” is probably a better description in that it encourages us to overcome it.

Before the Gun

Prior to the spray gun, painting was done with a brush and was enormously labor intensive, whether we’re talking early 20th century vehicles or even buggies and wagons, the production of which reaches back centuries. With the paintbrush, 100% transfer efficiency was achieved — not so with the spray gun. And, while the spray gun increases speed over the brush, it came at a price, and therein lies our previously mentioned challenge: overspray. Naturally, we don’t see the overspray challenge as our earlier counterparts surely did, but we do still have choices to make when we’re talking about masking solutions.

Purpose

To start, let’s loosely define the purpose of masking. I would sat it’s to protect the masked object. Protect it from what? In the paint shop, we focus on overspray protection, but there are other activities in the body shop that make protecting the masked object necessary. Welding, grinding, buffing, and dust protection are all worthwhile considerations and have solutions of one sort or another, some being overlapping, some not. But let’s get back to the paint shop.

Paper

While we have many paper offerings, great granddad was probably limited to either newsprint, parcel wrap or butcher paper. We learned over the decades that at the “critical edge” (the masked edge immediately adjacent to that which we were painting), mere overspray wasn’t the only challenge. The paint bleeding through the paper and, in some cases, sticking to the panel as a result of saturation was identified early. This was particularly problematic with reversible films such as lacquer. Different grades of paper were further developed as the paper needed to withstand multiple coatings applications as basecoat/clearcoat, three-stage and even four-stage paint technologies developed.

Additionally, different papers can be used for different tasks. While a standard green paper is fine for one-time use such as priming, you’ll probably want to step the quality up to perhaps a membraned paper for two- and three-stage painting operations.

There are also “check-hide” papers available with printed contrast designs which can be aligned at the critical edge to provide adequate coverage of the sprayed material. There are still fantastic craftsmen in some shops doing restoration-quality work where multiple primings and wet-sanding are common operations. A quality paper that can withstand that not only generates less masking trash, but also saves labor by avoiding repeated masking.

Tape

I suppose we also take masking tape for granted, but again, prior to the spray gun, there was likely limited application for it, and the tapes available were not the low-tack, pressure-sensitive tapes we know today.

Just as with paper, there are different grades of tape, even those of similar constructions, be it crepe or vinyl. Decreasing margins and Associated Products price increases generally drive the economy brands, but I submit for consideration that a sleeve of high-quality tape may prove to be a wise expenditure. With the proper balance of tack and tensile strength for critical edge applications, it saves time and frustration as the tape adheres well, withstands high baking temperatures and can be removed easily without splintering or continually breaking. Moreover, removing the residue left behind by some economy brands may require a greater expense in labor than the realized savings achieved at the purchase. That being said, a case of economy tape for general purpose taping jobs makes sense too, particularly when we’re talking “masking on masking” as opposed to masking directly to the vehicle. Labor generally costs more than material, so again, I suggest a sleeve of quality tape for specific situations.

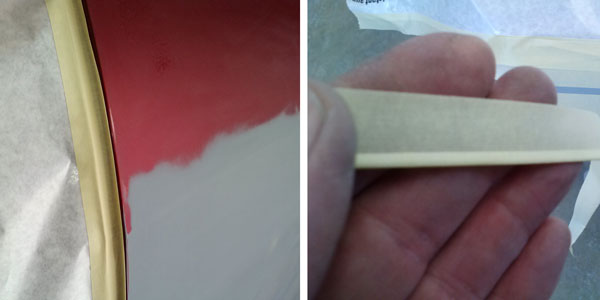

Vinyl tapes that prevent any edge-bleed and give us a crisp, clean edge is a necessity. Many painters prefer the critical edge to be undermasked by about an eighth of an inch, and then they apply a vinyl tape in the booth prior to spraying. This enables them to pull the tape at the critical edge after painting and avoid any peeling or lifting, which may occur if the paint film is dry and the tape is removed at the wrong angle. Always pull the tape at a 90-degree angle away from the edge. Most any “precision mask” operation, such as remaining faithful to the federal mandate to preserve R-DOT stickers, will benefit from vinyl tape.

Other tasks may require limited-application specialty tapes such as a round foam tape for overspray protection in areas such as fuel pocket/doors. Open the fuel door, apply the foam tape inside the pocket near the outer edge and close the door. This effectively creates a “dam” which prevents overspray from entering.

Another limited use tape will be a transition tape of sorts, whether it’s commercial or homemade (known as the folded tape trick). It produces a “soft” critical edge that works well in door jambs to prevent both overspray and hard-lines.

Decades ago, vehicle manufacturers were installing windshields and rear glass with large rubber window seals. The overlapping outer rubber lip could be lifted or “roped” with a length of quarter-inch rope. This lifted rubber lip could then be completely masked and allowed for easier sanding and cleaning of the substrate under the lip. Additionally, it prevented any bridging of the paint at the intersection of the rubber and the panel. There are different commercial products available designed to lift the rubber.

Plastic Sheeting

Depending on the shop layout, reverse taping and using plastic sheeting for the critical edges can be extremely productive, in both the masking and the unmasking operations. Traditional paper critical edges are also rendered more efficient when utilizing plastic sheeting, or car-bags in the common vernacular, as opposed to using 36-inch masking paper to finish covering the vehicle in the booth.

In years past, painters didn’t have the choice of using a plastic car bag at the critical edge as the paint wouldn’t adhere well when dry. Subsequently, it would flake off the plastic sheeting and flutter onto the fresh paint job and usually stick when the plastic was pulled during unmasking. Thankfully, that dragon has been slayed, but all the plastic bags I’m aware of are directional with regard to which side is paintable when covering the vehicle.

Other Protection

In the lacquer days, everybody had a set or two of reusable canvas wheel covers. They still exist today, but are less common and have been joined by disposable plastic wheel covers. Some painters are reverse taping the wheel well and stretching the plastic bag down the side, covering the entire wheel well, rendering the wheel cover obsolete.

There are several options of spray mask, some being easier to remove after the job is finished than others. Some remain wet and tacky, while others are dry to the touch. This isn’t a good solution for everyone, but it’s an excellent solution for some.

Tips and Tricks

There is typically something to be gleaned from everyone. Over the decades, I’ve collected a few tips and tricks I attribute to all my co-workers and colleagues, teachers and trainers, mentors and even helpers I’ve ever worked with or trained under.

In no particular order, they are:

- Wash your hands prior to masking. Presumably, the vehicle is clean and degreased, so whether it’s from a greasy pork chop sandwich or dust from dry guide coat, you don’t want to start contaminating the job with grease and smudges.

- If you’re using spray guide coat on your primer, apply it prior to removing the masking paper. This is not necessary with dry guide coat.

- When precision masking, keep in mind it requires “precision sanding” and/or “precision cleaning” as well, otherwise the precision masking isn’t as effective as you need it to be.

- When masking raw bumpers that have a molded in “step pad,” care must be taken not to precision mask into the very valley of any inside corner, and proper application of the color and clear becomes more critical to prevent a loaded or bridged edge. Apply the paint; don’t “pour it on.”

- There are situations when over-masking and then trimming back the tape with a razor knife is faster, cleaner and more accurate than traditional “precision masking.” Again, avoid paint bridging and don’t “pour the paint on.”

- Precision masking takes longer than simply masking. It’s usually in lieu of an R&I operation, so don’t give your additional time and skill away for free – charge for “precision mask.” It’s negotiable. If a roof rack pays six hours of labor for R&I due to the headliner needing to be removed, it’s likely you can get 1.5 hours precision mask. Ask for it. For the shop, cycle time can be improved by precision masking. However, if attention to detail isn’t strictly observed, paint edge peeling can occur at the precision masked edge, harming cycle time by way of a redo. Bring your “A” game and pay attention to detail.

- Mask with unmasking in mind. If you mask in such a way that unmasking is akin to an unraveling thread, you’ll not only save time unmasking but also because there won’t be a thousand pieces of tape and paper on the floor to pick up.

- While not suitable for color and clear application, inserting a piece of cardboard into the door-fender gap will prevent primer overspray from shooting the gap onto the A pillar.

- Leaving the masking in place when possible after refinishing (but prior to color-sand and buffing) allows the masking to perform double duty by keeping any sanding sludge or compound contained, reducing labor in the detail department.

- An old cotton bedsheet can be used for overspray protection, but you still need a critical edge of paper.

- Creating a temporary dam in door gaps to prevent “sealer creep” will help avoid a hard, dark sealer edge in the jamb, which typically requires a spot/refinish to correct.

Article adapted from BodyShop Business.