and leans out the fuel mixture.

When there is a lot of unburned oxygen in the exhaust — which may be from a lean fuel mixture, or if the engine has a misfire or compression leak — the O2 sensor will produce a low-voltage signal (0.3 volts or less). The PCM reads this as a “lean” signal, increases the duration of the injector pulses and adds fuel to enrich the fuel mixture.

When there is a lot of unburned oxygen in the exhaust — which may be from a lean fuel mixture, or if the engine has a misfire or compression leak — the O2 sensor will produce a low-voltage signal (0.3 volts or less). The PCM reads this as a “lean” signal, increases the duration of the injector pulses and adds fuel to enrich the fuel mixture.

A slightly different variation on this is the titania-type O2 sensor. Used in some older Nissan and Jeep applications, this type of sensor changes resistance rather than producing a voltage signal.

In recent years, the design of O2 sensors has changed.

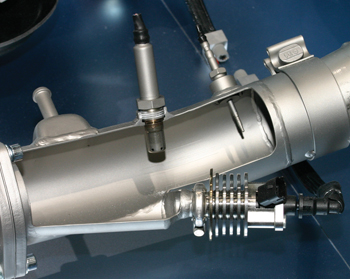

The ceramic thimble-shaped element in zirconia-type O2 sensors has been replaced by a flat strip ceramic “planar-”style sensor element.

The basic operating principle is still the same (the output voltage changes as O2 levels in the exhaust change), but the new design is smaller, much more robust and reaches operating temperature faster. You can’t see the difference from the outside because the tip of the sensor is covered with a vented metal shroud, but many O2 sensors from 1997 and up use the planar design.

Another change has been the introduction of “wideband” O2 sensors, which are also called “Air/Fuel” or A/F sensors. This type of O2 sensor also uses a flat strip ceramic element inside, but it has extra internal circuitry that allows the sensor to measure the exhaust air/fuel ratio with a much higher degree of precision.

It can tell the PCM the exact air/fuel ratio, not just a gross rich or lean indication as other O2 sensors do.

Monitoring Codes

First-generation O2 sensors typically have a limited service life, and may need to be replaced for preventive maintenance somewhere between 50,000 and 80,000 miles. O2 sensors on 1996 and newer vehicles typically have a much longer service life of 100,000 miles-plus, and do not have to be replaced unless they have been contaminated or damaged.

When O2 sensors get old, they can become sluggish and slow to respond to changes in exhaust oxygen levels. Typical symptoms include a drop in fuel economy and higher exhaust emissions.

When O2 sensors get old, they can become sluggish and slow to respond to changes in exhaust oxygen levels. Typical symptoms include a drop in fuel economy and higher exhaust emissions.

A bad O2 sensor should not affect engine starting, cause a misfire (unless the spark plugs become carbon fouled), or cause engine stalling or hesitation problems. A sluggish or fouled O2 sensor will typically read low (lean) and cause the engine to run rich.

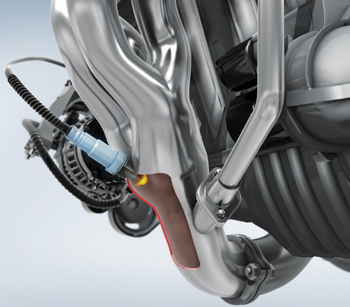

O2 sensors can be fouled by silicates if an engine has an internal coolant leak and the cooling system contains a conventional antifreeze with silicate rust inhibitors.

The O2 sensor can also be contaminated by phosphorus and zinc from motor oil if the engine has an oil consumption problem (worn valve guides or piston rings).

If the heater circuit inside the O2 sensor fails, or the sensor stops producing a signal due to an internal failure or a wiring fault (a loose or corroded wiring connector), it will usually set a P0130 to P0147 O2 sensor code.

The codes can be read by plugging a scan tool into the vehicle’s diagnostic connector. But, many times, other engine problems will set codes that may seem to indicate a bad O2 sensor, but in fact do not.

A P0171 or P0174 lean code, for example, means the O2 sensor is reading lean all the time. The real problem may not be a bad O2 sensor, but possibly an engine vacuum leak, low fuel pressure or dirty fuel injectors that are causing the engine to run lean.

An engine misfire, leaky exhaust valve or a leak in the exhaust manifold gasket that allows air into the exhaust may also cause this type of code to be set.

If an O2 sensor has failed and needs to be replaced, some aftermarket replacement sensors require splicing the sensor wires to accommodate all the different OEM connector styles. This type of O2 sensor provides greater coverage with fewer part numbers.

Others come with the same style connector as the original and are easier to install, but require many more part numbers for the same coverage.

Premature Failure

Premature Failure

Ever wonder what causes O2 sensors to fail? As O2 sensors age, they slow down. But this usually isn’t a

factor until the sensor has upward of 75,000 or more miles on it. So when an O2 sensor fails prematurely, the cause is often contamination.

Contaminants that can cause an O2 sensor to fail can come from a number of sources. If the engine has an internal coolant leak (due to a crack in the combustion chamber or a leaky head gasket), and the coolant contains silicate corrosion inhibitors (which conventional green coolants do but long-life orange coolants such as Dex-Cool do not), the silicates can pass into the exhaust and contaminate the O2 sensors.

Another source of contamination is the anti-wear ingredients in ordinary motor oil. But, the amount of phosphorus and zinc in motor oil has been reduced in recent years to reduce the risk of O2 sensor and catalytic converter contamination.

Every engine uses a small amount of oil and, over time, the contaminants can add up. As the engine accumulates miles, and the valve guides, rings and cylinders start to wear, oil consumption goes up. Consequently, in a high-mileage engine that is burning oil, phosphorus and zinc contamination of the O2 sensors and catalytic converter can be a problem.

If the O2 sensors are sluggish or have failed, they obviously need to be replaced. But replacing the O2

sensors will only temporarily restore the fuel feedback control system. Unless the oil burning is eliminated, the new O2 sensors will eventually suffer the same fate. The same holds true for a fouled catalytic converter.

You Can Bank on It

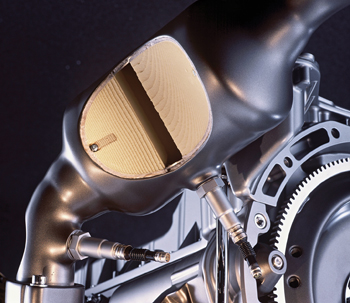

Did you know that many late–model engines can have as many as four or more oxygen sensors, so it’s important to know which sensor is having a problem if there is an O2 sensor fault code. The code will usually identify the problem sensor by its number and bank. However, this can be rather confusing unless you know how the sensors are numbered, and which cylinder bank is which.

On engines with multiple oxygen sensors, the sensors will be numbered 1, 2, etc. They will also be identified on V6, V8 and V10 engines by the cylinder bank they read (Bank 1 or Bank 2). Sensor 1 is always an upstream sensor in the exhaust manifold. Sensor 2 is usually a downstream sensor behind the converter — unless the engine is an inline four or six with two upstream sensors (as is common on BMW engines).

Sensor 3 or 4 would always be a downstream sensor. Bank 1 is the side that includes cylinder number one in the engine’s firing order.

Bank 2 is the opposite side. If you don’t know which cylinder bank is which, look up the engine’s firing order diagram.

On most General Motors V6 and V8 engines, Bank 1 is the left cylinder bank as the engine is viewed from above or from the driver’s seat. On Ford V6, V8 and V10 engines, it’s just the opposite. Bank 1 is on the right side as viewed from above or the driver’s seat. With Chrysler engines, most rear-wheel drive V6, V8 and V10 engines have Bank 1 on the left, but on their transverse-mounted V6 engines, Bank 1 is on the right.