Much of the focus of spark plug technology is on precious-metal designs featuring iridium or platinum tipped electrodes. These modern plugs offer many benefits, including longer service intervals, more complete combustion in leaner air/fuel mixtures and lower voltage requirements to develop sufficient spark for combustion. For some applications, precious-metal plugs are the only factory-recommended design. For many older applications (as well as a few modern ones), traditional copper-core designs are perfectly suited for the demands of daily driving.

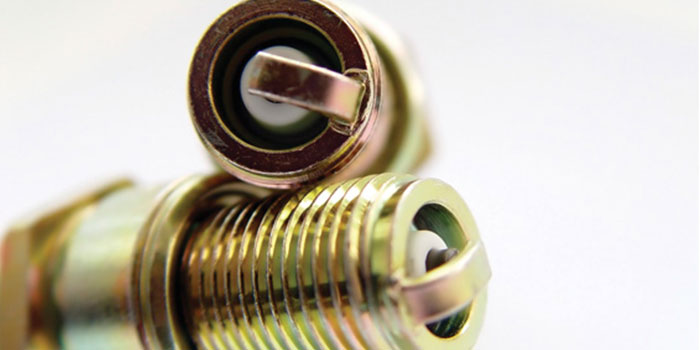

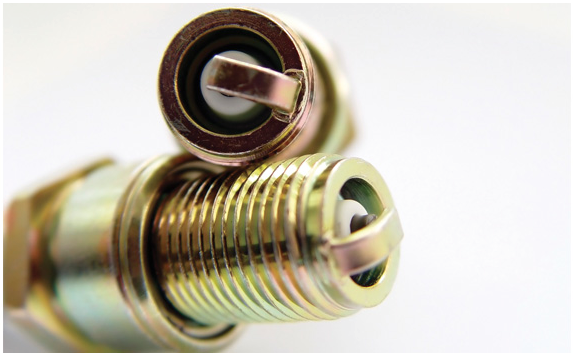

We should remember that even the most advanced precious-metal spark plugs are, at their heart, made of copper. The center electrode contains a copper core, surrounded by a nickel alloy, which helps combat wear and corrosion. Copper is used because of its excellent “thermal conductivity” (a fancy way of saying heat transfer). While most of us think of the spark plug primarily as a means of igniting the air/fuel charge, its secondary function is to draw some of that heat of combustion away from the cylinder. The plug’s ability to transfer heat is the measurement we refer to as “heat range.”

The phrase “copper plug” is a bit misleading, since even the least expensive copper-core spark plug has a hard metal center electrode tip. These tips are most often constructed of steel, usually alloyed with nickel. We know that copper is an excellent conductor of both electricity and heat, but it simply could not withstand the corrosive and erosive environment of the combustion chamber. Copper is softer and has a much lower melting point than any of the other elements used in spark plug construction, and would melt down within minutes if used as an electrode tip.

Of course, pairing the excellent conductivity and heat transfer capabilities of copper with more durable precious metals results in superior service life, but even the lowly “copper plug” has its place on the shelves of our part stores. From small engines to vintage cars, traditional plugs still make up a decent portion of our ignition sales, but there are other uses for copper besides satisfying the “lowest price possible” customer.

Racing and other modified engines are popular candidates for the traditional copper-core spark plug. Your local circle-track and drag racing customers may request traditional spark plugs, because they are both reliable and inexpensive compared to precious-metal plugs. Since most racers analyze and change their plugs frequently, the advantage of a long service interval is of little importance, and changing an $80 set of plugs every few weeks can be cost-prohibitive for most weekend racers. Fuel economy is rarely a priority when maximum power is desired, and racing ignition systems rarely lack for adequate voltage. Traditional plugs also are available in a wide selection of heat ranges to accommodate increased compression ratios, advanced timing, supercharging/turbocharging and the use of nitrous oxide. Even dedicated “racing spark plugs” are designed with these traditional nickel-steel electrodes.

Finally, in spite of the consumer and manufacturer trends toward precious-metal plugs, there is still a decent population of late-model vehicles that left the assembly line with a set of traditional copper-core spark plugs. From four-cylinder imports to a certain domestic V-8 requiring two plugs per cylinder, there is still certainly a case to be made for copper!

Article courtesy Counterman.