Have you noticed that it is getting harder to stock oil these days? For some vehicles, the same model may take three different types of oils, depending on the make or engine. The base model may require a 5W-30, while the V6 version may require a 5W-20, and the hybrid version may require a 0W-20.

In the old days, bulk 10W-30, 5W-30 or 10W40 conventional oil would work for the majority of the vehicles in your bays. But, new technology and more sensitive emission systems have forced shops to stock more grades and weights of oil. But why? The answer comes down to turbochargers, direct injection and catalytic converters.

What is in oil?

Oil has two components, the base stock and the additive package. The base stock, for lack of a better term, is highly refined crude oil. In some cases, the oil is refined to the point it can be called “synthetic” or a “man-made” substance.

The base stock is critical in determining the weight and performance of the oil. The refining process assembles chains of carbon that are consistent and free of molecules that could cause the long chains to fold up or break down. This refinement of the oil can make the oil less volatile and less likely for the long chains of carbon to break down when they are heated.

Additive packages are equal parts of art and science. Most people think the additive package just controls the lubricating properties of the oil. Yes, the additive package can control how the oil flows and sticks to parts. But, the more significant task of an additive package is to manage the wear and contaminants. The package also contains detergents that break down carbon deposits and dispersants designed to prevent carbon molecules from coagulating. The additive package also has chemicals that control the pH of the oil.

The other constraint on the additive package is the catalytic converters and emissions warranty. Ingredients like zinc, sulfur and phosphorus prevent wear to camshafts. But, these elements can contaminate the precious metals in the catalytic converter.

No matter how tight the piston rings or PCV system, some oil makes it past the exhaust valve. The converter on a vehicle must last at least 100,000 miles to meet the emissions warranty. The best way to improve the chances of the converter lasting to the end of the warranty is to reduce the amount of zinc, sulfur and phosphorus in the oil. New oil standards set limits on the amount of substances that can damage the catalytic converter.

Engineers and chemist have been working on replacement additives that do not damage the catalytic converter, but improve the additive package’s performance.

What is Viscosity?

Oil viscosity refers to how easily oil pours at a specified temperature. Thinner oils have a water-like consistency and pour more easily at low temperatures than heavier, thicker oils that have a more honey-like consistency. Thin oil is good for easier cold-weather starting and reducing friction, while thick oil is better for maintaining film strength and oil pressure at high temperatures and loads.

The viscosity rating of motor oil is determined in a laboratory by a Society of Automotive Engineers (SAE) test procedure. The viscosity of the oil is measured and given a number, which some people also refer to as the “weight” (thickness) of the oil. The lower the viscosity rating or weight, the thinner the oil. The higher the viscosity rating, the thicker the oil.

Motor Oil Viscosity Rankings

Viscosity ratings for commonly used motor oils typically range from 0 to 50. With multi-viscosity oils, a “W” after the number stands for “winter” grade oil. The numeric value of the first number (for example, the “5” in 5W-20) is a measure of the pour point of the oil expressed in degrees Celsius when the oil is cold. The rating is determined in a lab using a cold crank simulator and mini-rotary viscometer test. The oil weight is its viscosity index at 100° C (the boiling point of water).

Low-viscosity motor oils that pour easily at low temperatures typically have a 0W, 5W or 10W rating. There are also 15W- and 20W-grade multi-weight motor oils. Higher-viscosity motor oils that are thicker and better suited for high-temperature operation may include multi-grade oils, or single-weight oils such as SAE 30, 40 or 50.

Multi-Viscosity Motor Oils

Most modern motor oils are formulated from various grades of oil so that they will have the best characteristics of both thick and thin viscosity lubricants. Multi-viscosity oils flow well at low temperatures for easier starting, yet retain enough thickness and film strength at high temperatures to provide adequate film strength and lubrication.

Thin oil, such as a straight SAE 10W oil designed for cold-weather use, would probably not provide adequate lubrication for hot-weather, high-speed driving. Likewise, a thicker, high-temperature oil, such as SAE 30 or 40, would probably become so stiff at sub-zero temperatures that the engine might not crank fast enough to start.

Multi-viscosity grade oils have a wide viscosity range, which is indicated by a two-number rating. Popular multi-viscosity grades today include 0W-20, 0W-40, 5W-20, 5W-30, 10W-30, 10W-40 and 20W-50. The first number with the “W” refers to the oil’s cold-temperature viscosity rating, while the second number refers to the oil’s high-temperature viscosity rating.

Motor oils that have a broader range viscosity rating such a 5W-30, 5W-40 and 0W-40 are blended with more base stocks and additives. Because of this, it may be harder for these oils to remain in grade as the miles accumulate (which is why GM does NOT recommend using 10W-40 motor oil). They say it breaks down too quickly and does not stay in grade as long as 10W-30 or 5W-30. Also, oil with a lower winter rating like 0W-20 or 5W-20 will contain a higher percentage of thinner base stock oil (which is typically a synthetic oil). This requires more viscosity improver additives to achieve the same high-temperature rating as a 10W-30, 10W-40 or straight 30- or 40-weight oil.

Most vehicle manufacturers today specify 5W-20 or 5W-30 for newer vehicles for year-round driving. Some cars specify 0W-20, 0W-30, 0W-40 or 5W-40 for their vehicles. In 2019, you will see late-model vehicles that will require a GF-6 oils that require 0W-16 oils that can help improve fuel economy.

Zero-weight oils are designed to reduce emissions during warm-up. If the wrong oil is put in the crankcase, it will change the three to five minutes it takes to bring the combustion chamber up to temperature. This will also alter how the variable valve timing works, and it can also have implications for the catalytic converter.

Always use the motor oil viscosity recommended by your vehicle manufacturer. Using a different viscosity (thinner or thicker) may cause oil pressure and oil supply problems, especially in late-model engines with cylinder deactivation and/or variable valve timing (VVT).

Why Synthetic?

Some consumers and technicians think if the oil is changed every 3,000 miles with conventional oil, they are preventing problems and saving the expense of having to purchase the recommended synthetic oil. The reality is that no matter how often the conventional oil is changed, the oil is not suited for the late-model engine.

Convention oils typically have high volatility numbers. If oil has a high-volatility number, it vaporizes more quickly when exposed to heat, no matter how many times it is changed. This means that the oil can become thicker over time and won’t lubricate as well. It also means that there is a higher volume of oil vapor the PCV system has to process.

Crankcase vapors can be loaded with hydrocarbons and stick to the intake valves, head and piston, causing a carbon deposit problem. Synthetic oils have much lower oil volatility. This reduces oil vapor and carbon deposits on the intake valves.

New Oil Standards

Turbocharged direct-injection engine technology is becoming more and more commonplace. The technology is being used on all vehicles from SUVs to compact cars to get more power out of less displacement. But, these new engine technologies require better oil.

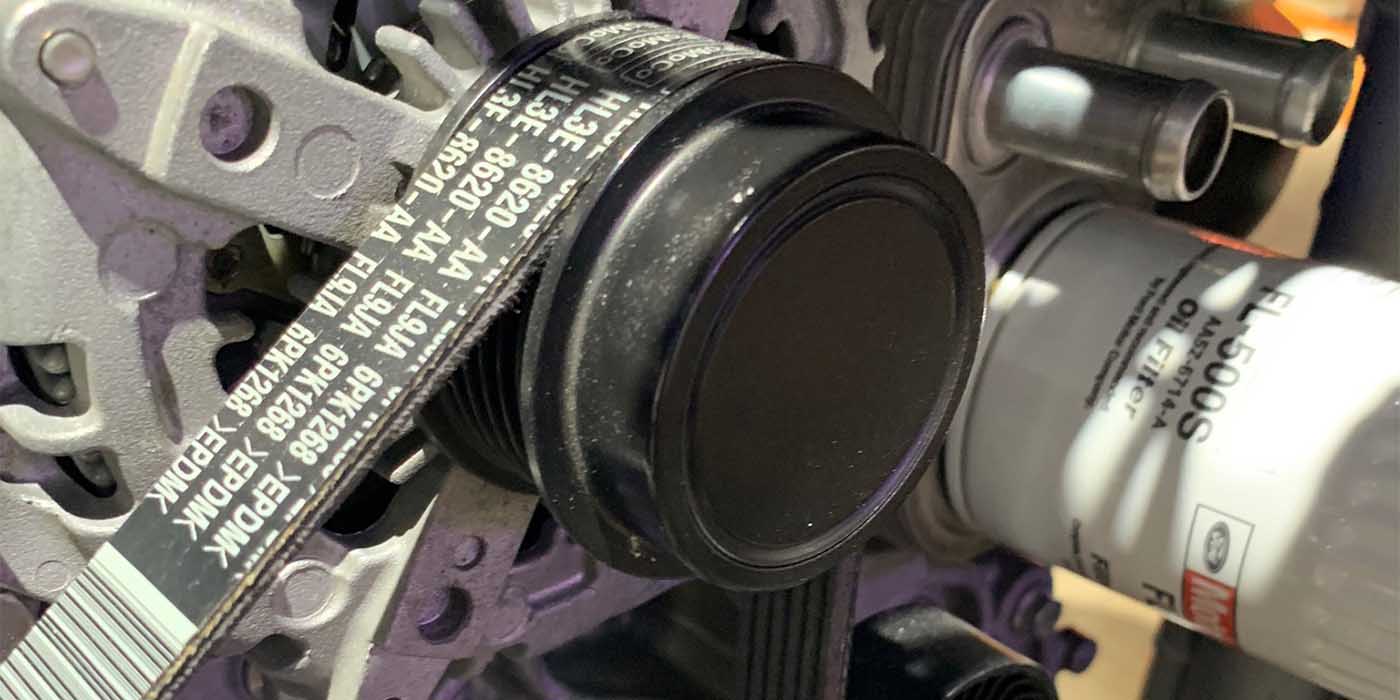

Turbochargers need oil for lubrication and cooling. The turbocharger can spin at more than 100,000 RPM and the heat generated by the exhaust turbine is tough on oil.

Direct injection increases the pressures and temperatures of the combustion chamber. These conditions can increase blowby gases and particles of carbon in the oil. If the engine is experiencing abnormal combustion due to a lack of maintenance, carbon particulate levels in the oil can increase. These particles can stick to each other and eventually reach a size where they can cause wear to components like timing chains and camshafts.

New oil specifications like SN-Plus and GF-6, and manufacturer specifications like GM’s Dexos have been built around these new engines with direct injection and turbochargers. Not using the oil that matches the specification for the engine can have consequences.

Article courtesy Underhood Service.