Oil specifications are not about the ingredients in the oil, but how the oil reacts to standardized conditions. Oil specifications are set by industry groups or the vehicle manufacturer. Testing procedures are not “trade secrets,” as they are shared with the companies making engine oils. These document the specific tests, equipment requirements and limits needed to pass the standards.

The information does not list ingredients or how they should be mixed. It is up to the formulator to select the right base stock oils and additive package ingredients. A single test can’t be skipped or failed to be able to say an oil can meet an ILSAC, API or OEM specification.

The testing must also be carried out in a laboratory that is accredited by a third-party auditor. Every aspect of the facility must follow specific guidelines, ranging from how paperwork is filled out, to the periodic calibration of the equipment. Testing protocols and procedures for a single oil product significantly increases the final price.

Some OEMs also require the oil companies to pay licensing fees so they can officially promote that the oil meets the specifications. These fees can add 15-20% to the price of the oil.

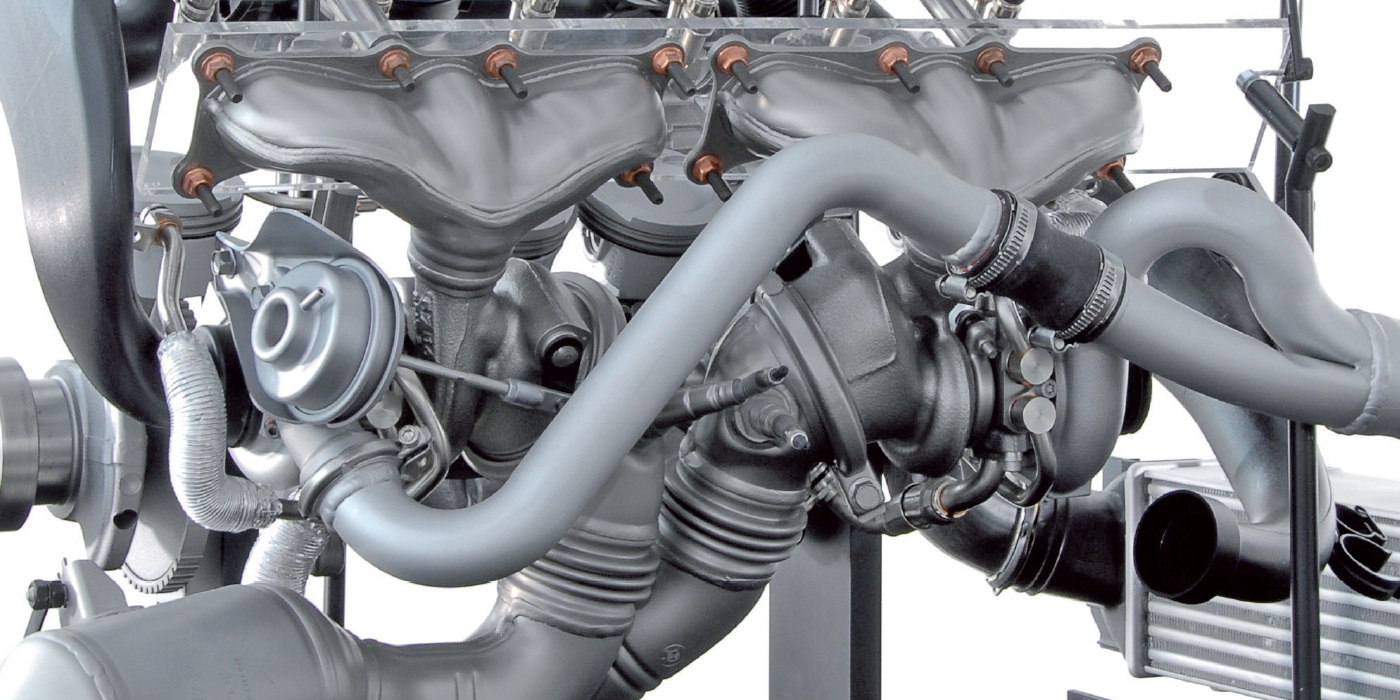

Oil standards and certifications change as engines change. As engines become more efficient and have higher compression ratios, carbon deposit levels on the pistons have been lowered in most specifications. Also, turbochargers have forced industry associations and OEMs to improve the thermal stability of oil to properly lubricate the turbine’s shaft. This is why new oil standards like GF-6 and SN-Plus will soon be on shelves.

Bench Tests

For some certifications, it might require 50 or more tests to be conducted outside of an engine. These are called bench tests. An example of one is a bench test where the oil is mixed with 10% water and 10% E85. To pass the test, the water and ethanol can’t separate from the oil during a 24-hour period. Other tests for volatility require a sample of oil to be placed on a hot surface for a specific amount of time. The weight of the remaining oil is measured to calculate the volatility of the oil. Other tests measure the compatibility of the oil with gaskets and seals.

Engine Tests

Behind every oil specification is an engine or engines, in some cases. For ILSAC GF-5 tests, the testing procedure used common engines like the Ford 4.6 V8, GM 3.6 High Feature V6 and engines from other manufacturers, both import and domestic. Engines are used for specific test series that target a specific oil performance characteristic.

Engines are run on test stands under specific parameters for temperature, load and time. These tests simulate some of the worst conditions the oil may experience in a vehicle. After a test, the engine is typically torn down to measure a specific characteristic. In the case of carbon deposits, the pistons or valves will be weighed before and after the test to determine deposit levels. For wear testing, the levels of copper and other bearing metals are measured in the oil.

One of the reasons oil specifications are changing is that the engines used for testing go out of production. This can make carrying out testing difficult because for the test to be consistent, parts like pistons, gaskets and rings must be the same for all of the years the tests are carried out.

Creating oil is a balancing act for the engineers and chemist. An additive might reduce bearing wear, but it may also contaminate the catalytic converter and prevent the catalyst beds from reducing unburned hydrocarbons. This could force the company to look for different additive package ingredients that might not be more expensive or are not even invented yet.

Article courtesy Underhood Service.