As our resident oil expert John Martin, who was a scientist at Lubrizol in a past life, summed it up: Oil used to be easy in the ‘60s and ‘70s. Now it is complicated.

Passenger car motor oil (PCMO) has undergone numerous changes over the years. What affects performance engine builders the most, however, is the reduced level of the antiwear additive known as ZDDP (zinc dialkyl dithiophosphate) to 800 parts per million due to its harmful effects on catalytic converters. Previous oil formulations had as much as 1,200-1,500 ppm of ZDDP.

The latest PCMO formulations are aimed at reducing tailpipe emissions and increasing fuel economy. They also must extend the life of catalytic converters, which is not an issue on race engines. Around 1996, many OEMs were introducing OHC engines with roller followers that reduced the need for high levels of antiwear additives. Before then, performance engines of the early ‘90s could share the same oil as production engines without consequence. Today, if you use a street oil (API approved) in many performance applications, it will not withstand the loads, especially when breaking in flat tappet camshafts.

Due to lower ZDDP in PCMOs, some engine builders and enthusiasts have switched to diesel oil with higher concentrations of the additive. However, experts warn that 1,200 ppm (found in diesel oil) may be on the edge of what an engine builder needs. Many grassroots racers can get by with diesel oil in mild performance applications. But if you are trying to squeeze out every ounce of power, it is best to run oil that is designed for that purpose (which is where race oil comes into play).

Some of the additives in diesel oil that help keep the soot in suspension can work against a racing application and may leave some power on the table compared to racing oil. Racing oil experts say their oils provide better wear protection than API formulated oils and help produce horsepower because they also reduce internal drag (friction).

New PCMO Tests

Gasoline direct-injected (GDI) and turbocharged direct-injected (TGDI) engines have left manufacturers scrambling for solutions for how to solve low-speed pre-ignition (LSPI). The OEMs have collaborated with oil manufacturers (API and ILSAC) to create a new standard that deals with the issue. A new API/ILSAC classification called GF-6 is set to be introduced in May of this year, but it has been a long road to get there. Three new engine tests had to be developed, and all the old ones had to be updated. The baseline engines that were used for the older tests were updated to represent more of what is on the road today.

Overall, there are seven new GF-6 oriented tests. There are four replacements for the current ASTM Sequence III, IV, V and VI tests. Three new tests include a revised Sequence VI test for qualifying low-viscosity oils and the Sequence IX test for LSPI and X for chain wear.

Many of the tests from GF-5 were at the end of their useful life, according to API. Replacement parts for the older engines were almost gone. So, API had to validate the new replacement tests, too. Sequence IIIH has replaced Sequence IIIG is an oxidation and deposits test. This test has been updated to use a 2012 FCA 3.6L port fuel injected (PFI) engine. The IIIG test ran a 1996 GM 3800 V6 engine that is no longer in production.

The VH test replaces the VG, which was one of the oldest tests under the GF-5 that used a 1994 Ford 4.6L V8. The replacement test now uses a 2013 Ford 4.6L to evaluate the ability to prevent sludge and varnish on engine parts. Sequence IVB is a cam and wear test run on a 1.6L 4-cylinder Toyota engine. This test is a replacement for the current IVA test.

The LSPI test is brand new and uses a Ford 2.0L GDI EcoBoost engine, which is in addition to a new test for timing chain wear. The chain-wear test determines how blow-by from fuel dilution and contamination of the oil leads to increased chain wear. The 2.0L Ford engine will be used to run this test also.

The Sequence VIE Fuel Economy Test uses a 2012 GM 3.6L engine that replaces a 2008 2.6L Cadillac. This test measures how to improve fuel economy. Another version of this test (Sequence VIF) is used to measure the fuel economy in low viscosity oils.

To confuse things even more, API/ILSAC are splitting GF-6 into two specifications; GF-6A and GF-6B. GF-6A is compatible for vehicles currently using SN PLUS or Resource Conserving SN. Oils in this category have viscosities as low as 0W-20. It will address chain wear and LSPI, while also aiming at the latest GDI and GTDI engines.

The latest engines will go even a step further and require 0W-16 (i.e., Toyota and Honda at the moment). Rebuilders will have to pay close attention because using the wrong oil could cause problems in the long run. A new API symbol will be used to specify GF-6B. The mark looks more like a shield than the traditional API Starburst, and it will be located on the front of the oil bottles.

Racing Oil

One of the difficulties with the way racing oils are marketed today is that engine builders and racers have to decide which oil companies to believe since there are no specifications to compare. And this likely won’t change anytime soon because racing oils are a niche market compared to the size of the passenger car market. Lab tests would be needed to define it as a category. For most race oil companies, this is not feasible on their own. Perhaps they could do it if they worked together like API/ILSAC? Food for thought.

Experts warn not to get lost chasing down the oil with the highest ppm like it is the Holy Grail because there’s more to it than that. The amount of detergents and the balance to antiwear additives is another big difference between racing oil and street oil. Detergents clean the sludge and build up in the engine, which is essential for street engines that operate in short spurts and at lower operating temperatures. But race engines don’t need as many detergents because they are drained much more frequently.

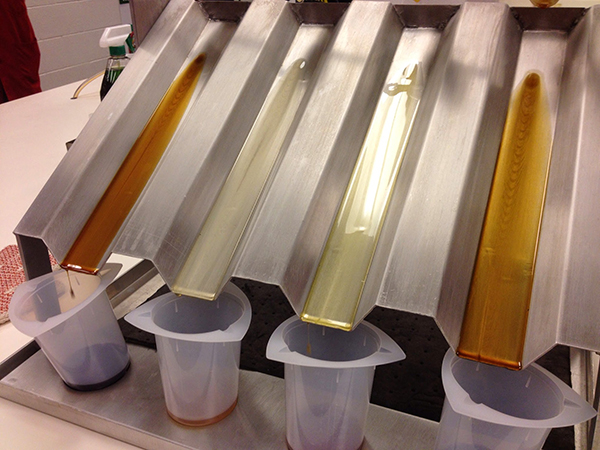

Motor oil is about 85% base-stock from one of, or a blend of, five groups of base-oil classifications. Group I base stock is the least refined and is used for straight-weight, conventional motor oils. Group II has fewer impurities and is more refined. It is used for multigrade conventional motor oils. Group III base stock is categorized as synthetic since it is even further refined. Group IV base stocks are PAOs (Polyalphaolefin) synthetics, and Group V is essentially anything that will not fit into the previous four categories.

Most racing oils have a synthetic base oil or blend, but some high-quality mineral-based oils are also used today. The use of synthetic oils has not necessarily increased performance, but they are less volatile to heat. However, synthetic base oils have created a shift to lighter viscosity oils that reduce parasitic power losses, which is most beneficial in a racing application.

Additive chemistry and overall formulation are more critical than base oil type alone. You cannot fairly judge an oil by one or two components. Synthetics allow engines to run higher temperatures and longer drain intervals, but mineral oils can also be useful in race applications. There have been more gains in mineral base oils over the past several years. Synthetics will outperform mineral oils in extreme heat and cold but are not always the better choice. Mineral oils are often a more affordable option, especially if you are draining it frequently.

As racers and engine builders, we are continually looking for ways to make more horsepower and turn more rpm. However, increasing power and rpm also increases the load that the oil must hold on a thin film of lubricant between metal parts. Racing oil companies are developing lubricants that can carry higher loads on a thinner film than ever before. They are designed to handle higher loads without increasing wear – which is the biggest challenge. We don’t endorse one brand or another here, but the ones that work best have experience and testing to prove they do what they should.

Racing and the automotive industry are a long way away from the ‘60s and ‘70s, which many people call the glory days. With everything from our toothbrushes to telephones getting more complicated, at least engine oil doesn’t come with an app yet.

Article courtesy of Engine Builder magazine.