Original equipment and quality aftermarket serpentine belts are engineered to last up to 90,000 miles but some drivers may find their replacement belt doesn’t last as long. They can’t blame the belt – the only reason a quality aftermarket belt may not wear properly is that the system that it is placed into has issues.

Yes, you’re dealing with a system. The belt is part of a vehicle system that has a lot of moving parts and will see different loads depending on the accessory being driven during the operation of the vehicle.

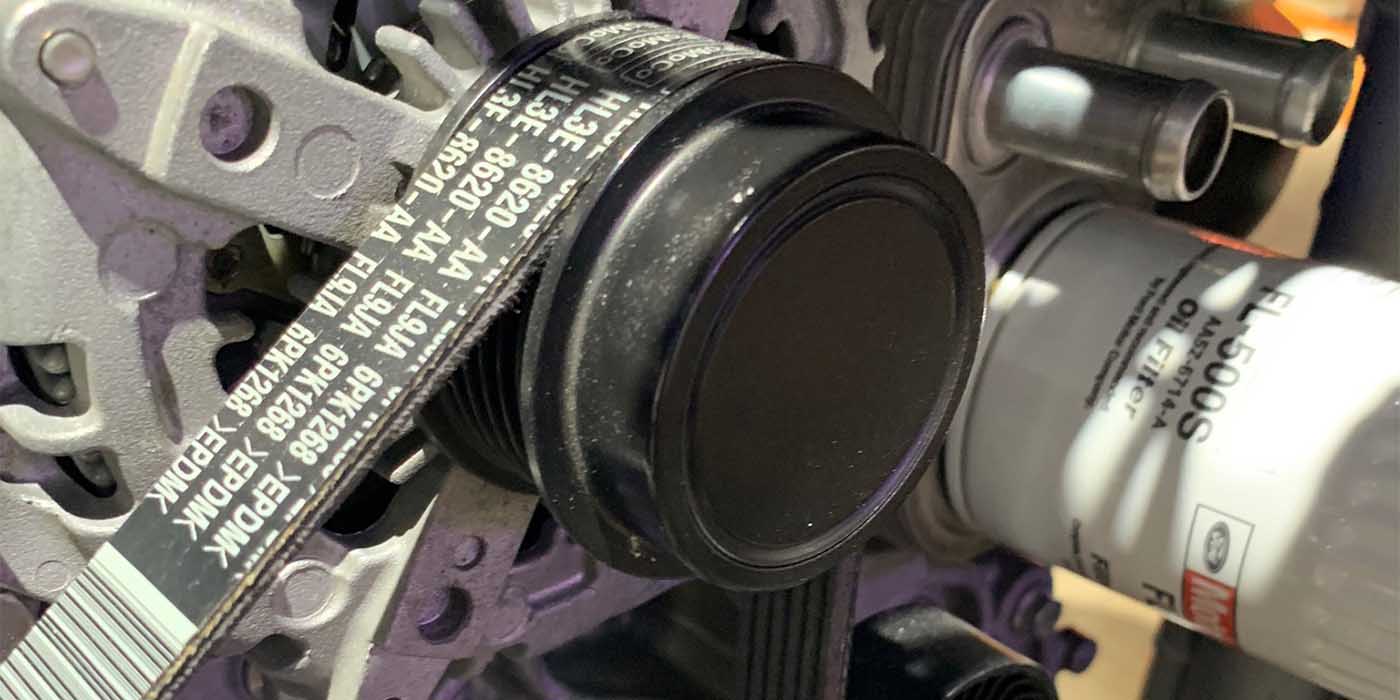

Quite a few serpentine belts are replaced the first time by themselves, usually during a routine visual service check – perhaps during an oil change or other under hood procedure. Sometimes it is because a customer has heard some type of belt noise. If only the belt is being replaced, there can be issues down the road.

Why? The problem, of course, is that the root cause is more than just the serpentine belt.

Spring-loaded belt tensioners wear at the same rate as the belt – In a quality aftermarket tensioner, the vibrations caused by the engine are absorbed by the damper in the tensioner…the damper acts like a shock absorber…the damper is the part of the tensioner that begins to wear with those vibrations and causes excessive arm movement. This creates belt flutter, an inefficient transfer of power and can cause accessories to underperform and accelerated wear of the newly installed belt.

Idler pulleys and tensioner pulleys have sealed ball bearings and are designed with the same typical service life as the serpentine belt and the tensioner. Worn-out bearings can cause a number of problems in the system. If the pulley is operating at an abnormal angle it will create excessive wear on one side of the belt. In extreme cases, a seized pulley can break off its mount.

Any pulley misalignment or misalignment in the system can cause belt chirp and will accelerate belt wear.

Belt materials are more advanced than ever. Some belts are even designed with Aramid-cord construction which reduces noise, vibration, and complaints. But, belts regardless of advanced construction, are still affected by fluid leaks that can cause significant damage.

Petroleum-based fluids will soften belt material, causing the belt to weaken, wear faster and, in some cases, cause belt delamination. Along with oil-based leaks, coolant leaks will cause physical belt damage and can cause the belt to slip on the pulleys.

It’s easy enough to simply replace a belt and get the customer on her way – in fact, belt replacement is one of the simplest jobs in the shop and may be regularly handled by your least-experienced technician. Consider whether that’s the best procedure for your shop. There may be more required than just what meets the eyes – or the ears.

Create a best practice that includes a standardized inspection of the belt drive system and an installation process that each technician, regardless of their experience, should follow.

The most efficient solution for belt drives is the installation of a belt kit that includes a new belt, belt tensioner and idler pulley for the application. Installation of the kit can reduce comebacks, save time by performing the complete belt service at one time and increase sold hours.

This will ensure that each service visit is maximized from the customer and shop’s perspective. Time is the most valuable resource in your shop, whether you are a customer, manager or technician. Following this process each and every service visit will go a long way toward increasing customer satisfaction and profitability.

This video is sponsored by The Group Training Academy.