The modern engine measures two things extremely well: the amount of air going into the combustion chamber with the mass airflow sensor (MAF); and the byproducts that are generated by the combustion event with the oxygen sensor. These measurements allow the engine’s computer to put the right amount of fuel and spark into the cylinder to give the most efficient and cleanest combustion event.

Fuel-injected engines are able to compensate by changing fuel trim that influences the open times of the fuel injectors. Since there is less oxygen, the engine will need less fuel. Less fuel means a leaner fuel trim and typically less power. This adjustment comes at the detriment of performance by taking away fuel.

It also works in the opposite direction. If unmetered air makes its way past the MAF sensor, the oxygen sensor will detect a lean combustion event. The ECM will then instruct the injectors to pulse for a longer period of time. This increases fuel consumption and decreases fuel economy.

The ECM can compensate only so long before it becomes unbalanced and can no longer add or restrict fuel to achieve a proper oxygen sensor reading. This is when codes are set for a too rich or too lean fuel trim. A restrictive air filter may not set a code, but the restriction and compromised fuel trim will hurt the power and efficiency. Replacing the filter and resetting the fuel trims may return the system to normal.

Understanding Air Filters and Fuel Trims

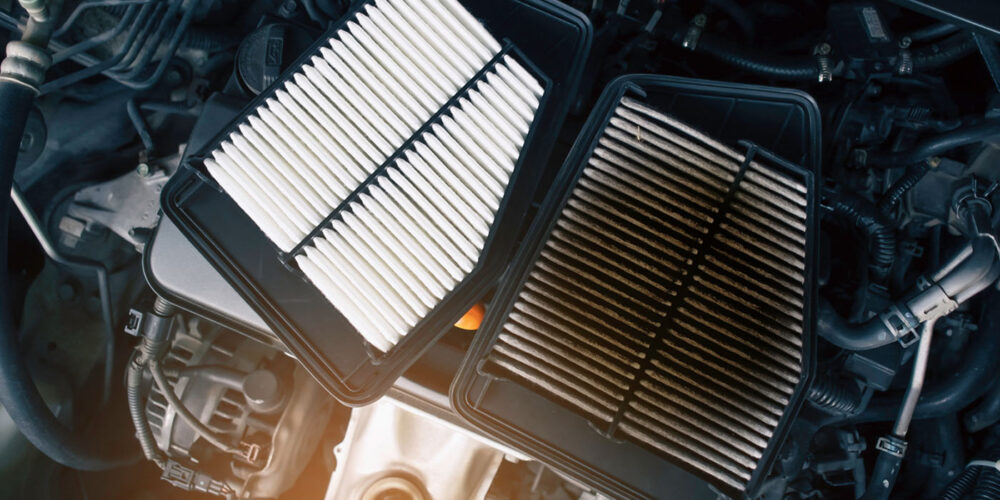

If a filter is clogged or restrictive, it will show a negative fuel trim value, which means the engine computer is subtracting fuel – decreasing the pulse width or on-time of the fuel injectors – to reduce the amount of fuel injected into the engine. This is done to lean out the fuel mixture to compensate for what it perceives as a rich running or choked condition.

Positive fuel trim air filter diagnostics are a little more complicated. If an air filter or air induction system is delivering more than the normal amount of air, it will cause the oxygen sensor to detect a lean condition. It will add more fuel and cause the fuel trim to be positive. Some possible factors:

- Collapsed Filter: This could be caused by a clogged wet filter that has become damaged, ripped or dislodged by the vacuum generated by the engine. It will typically flow better than a clean filter.

- Blocked MAF Sensor: If a filter is made of low-quality materials, pieces of the filter media can be dislodged and block the MAF sensor. They can even damage hotwire MAF sensors.

- Damage to Air Filter Housing: If an air filter housing is damaged, cracked or cannot create a seal around the filter, the air may create turbulence or allow unmetered and unfiltered air to get past the MAF sensor.

- Bad Filter Design: A lot of engineering goes into an air filter. Base fuel trims are calculated using a stock filter. If a replacement filter used the wrong materials, pleat design or gasket material, it can influence fuel trims.