A tire’s sidewall markings can tell you everything you need to know about its performance characteristics. Have you ever wondered what a tire’s speed symbols mean and how the system was developed?

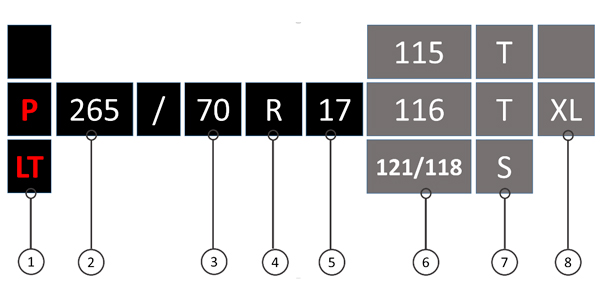

Figure 1 shows a typical tire sidewall and the information on it. Item No. 7 shows the tire’s speed symbol. The letter indicates the maximum speed that a tire can safely be driven over time. It is the fastest speed a tire can handle based on its design. The higher the speed rating, the better control and handling you’ll have at higher speeds.

The speed rating system was developed to help control the safe performance of tires at standardized speeds ranging from A to Z.

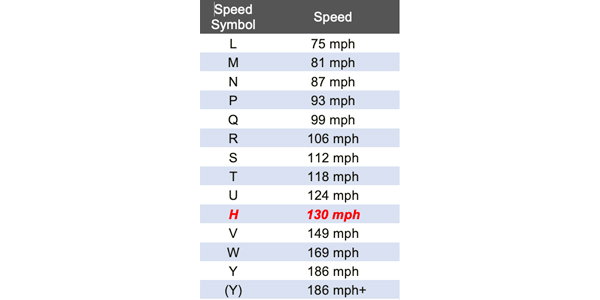

Table 1 illustrates the speed capability of tires. Speed ratings were established to match the speed capability of tires with the top speed of the vehicles to which they are applied. A tire’s speed rating does not suggest the speed of the vehicle, and only shows the maximum capability of the tire. With the exception of letter H, as letters move from A to Z, the speed capability of the tire increases. Tires with a speed symbol Y are capable of speeds up to 186 mph. Anything above 186 mph is indicated with the Y bracket “(Y)”. Most tires using speed symbols Y and (Y) also change the size description from R to “ZR” indicating higher speed capability.

Speed lettering was first developed in the 1960s by European engineers to create a standard method of speed control and communication to consumers. When tire speed ratings were first developed, only three existed: S, H and V. As tire technology further developed and new speed classes were introduced, the ratings table expanded to include the full alphabet. It was decided to keep the letter H at speed 130 mph as an exception to manage the older tires in the market.

Speed Rating Tradeoff

Why should we have limitations on speed when we buy a tire? Why can’t all the tires be designed for (Y), regardless of usage, so consumers have peace of mind about their tires’ speed capability? These questions (and others) may have popped into your mind – or your customers’ – when buying tires.

It would be ideal if all tires could be designed with a (Y)-rating, but like everything else in the tire world, it’s all about tradeoffs. When engineers design a tire, they are consistently in battle with tradeoff considerations. Actually, this battle is not only fought in tire design; it also concerns any engineering component. As a more relatable example, the designers of the iPhone are fully capable of designing a phone that doesn’t need a charge for a week. It would be amazing, right? So while it’s doable, you would probably need luggage to carry around the 25-pound phone.

When it comes to the speed symbol, engineers fight with the heat generation and heat dissipation of the tire. It is a fact that higher speed creates more heat, which is the number one enemy of a tire. Heat creates separation and separation creates tire failure. Tire engineers try to design each tire to generate less heat and dissipate it as quickly and efficiently as possible. As speed increases, so does the heat generation. By designing a stiffer construction along with a compound designed for better heat dissipation, the engineer will try to control the generation of heat. But this will not be enough, so engineers will then try to decrease the material in the tire to help with quicker heat dissipation. Tread depth reduction can achieve this, but it will also decrease the wear capability of the tire. While it may be desirable to create a 215/60R16 with a Y-speed symbol for a Nissan Altima, it would be unreasonable to ask Altima owners to accept a 25,000-mile treadlife warranty.

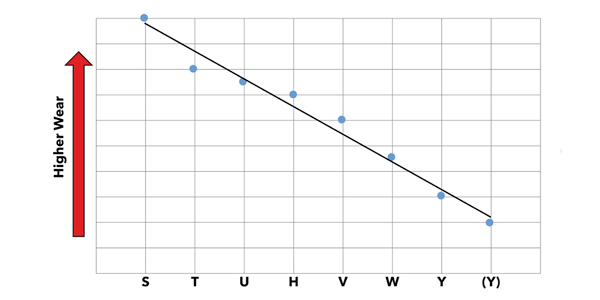

Figure 2 shows the direction of target conflict between tire wear and the speed symbol. Wear would not be the only tradeoff. Higher-speed tire development often improves tire handling, tire steering and high-speed maneuverability but decreases wear, comfort and cold-temperature capability like snow and ice traction.

Speed Rating Testing

Tire manufacturers determine a tire’s capacity for heat and speed using a testing machine based on the Federal Motor Vehicle Safety Standards (FMVSS), Economic Commission for Europe (ECE) or often both. For the ECE test, a tire is properly inflated and mounted on a wheel attached to a testing machine. The tire is pressed against a metal drum with enough pressure to simulate a realistic load. Starting at a speed of 40 km/h (about 25 mph) lower than the proposed rating level, the tire is spun for 10-minute increments at higher and higher speeds, until it reaches the target speed. Lastly, the tire spins for 10 minutes at the target speed. Some tire manufacturers would like to see the tire perform without failure for one or two steps above the target speed before they qualify the tire. Other manufacturers may stop the test at the targeted speed. Tires that finish the desired stage without sign of failure are considered speed-approved.

Final Thoughts

Now you know some of the history and science behind how and why a tire is assigned a speed rating. But speed rating is still one of the most misunderstood aspects of a tire and the tire’s performance. So, to clarify, speed rating is not a performance rating. While many tires designed for higher speeds can also have higher levels of handling and grip, a Y or (Y) speed rating doesn’t necessarily guarantee better handling or performance than any other speed rating on a tire. And, while the chart trends that way, a T or H speed rating does not guarantee better mileage than a tire with a V rating. It does reveal, however, that such a tire is more difficult to engineer. In the end, a speed rating is just a speed rating. As important as that specification is to the speed capability of the tire, it is a mistake to assign other attributes to a tire’s overall performance without knowing more.

This article appeared in Tire Review.