essure fuel pump and camshaft lobe from wearing out. In most cases, oil refiners have gone to much higher quality base oils to prevent wear on the high-pressure fuel pump and cam lobe. Again, it’s vitally important to make sure that the replacement oil is either OE oil or is approved by the OE manufacturer.

As for older, performance pushrod, flat-tappet engines that are not equipped with catalytic converters, specially branded performance oils are available with anti-scuff additives to prevent camshaft and valve lifter wear. In addition, zinc-based “ZDDP” additives are also available to enhance the anti-scuff qualities of over-the-counter motor oils. Again, these oils and additives are not intended for vehicles equipped with catalytic converters.

Causes of Sludging

Neglected oil change intervals can ruin the best engine oils. As engine oil accumulates miles, it becomes contaminated with carbon, water and various acids, all of which are a by-product of internal combustion and which will form a film of black, gooey sludge on the interior parts of the engine.

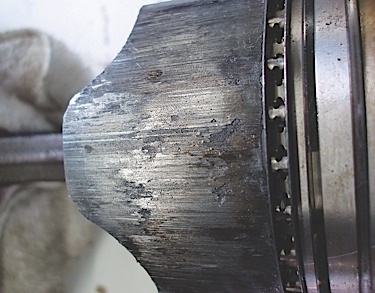

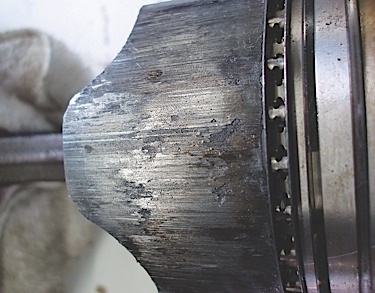

Cold-engine operation accelerates the formation of sludge because the oil temperatures aren’t sufficient to evaporate accumulated moisture. Oil sludging is also aggravated by short-trip, cold-weather driving and by thermostats that are stuck open. See Photo 1.

When the engine is operated at high speeds and temperatures, sludge often dislodges and clogs the oil filter. Since most oil filters incorporate bypass valves that allow the lubricating oil to flow around a clogged filter media, the dirty oil can pass directly into the engine and clog small-diameter oil galleries.

Getting Dirty

In any case, heavily sludged oil will eventually clog the engine’s oil pump pickup screen, oil filter and oil galleries. The initial symptoms of oil starvation are engines that become noisy during cold start-up and oil pressure gauges that rise very slowly. Broken timing belts are also symptomatic of oil starvation on overhead camshafts. Because the damage usually includes the crankshaft and piston assemblies, don’t be too eager to quote a cylinder head replacement as the cure for a seized camshaft. See Photo 2.

All too often, the detergents contained in fresh oil will accelerate the clogging of oil pump screens and oil filters by loosening accumulated sludge. Volumes of engine sludge and dirty engine oil also easily clog today’s compact oil filters. If the oil filter bypass valve opens during cold starts, more sludge and dirt will pass into the engine bearings and reciprocating parts. In addition, engine life is drastically shortened when operated at extreme loads and temperatures with badly degraded engine oil. See Photo 3.

The problem with any heavily sludged engine is that internal repairs tend to dislodge even more sludge into the oil stream. Because attempting to clean an engine in-chassis is both expensive and risky, you can best address the situation by replacing or rebuilding the engine.

Interference with VVT

Most modern engines are very susceptible to lubrication problems because they are equipped with variable valve timing (VVT). A pulse-modulated control valve that meters oil pressure to a hydraulic piston or vane-type camshaft timing phaser controls the amount of advance or retard. A separate valve-timing sensor is used to monitor VVT position.

Quite clearly, the phaser must react to small changes in oil pressure. Since sludge can interfere with the smooth modulation of the oil pressure contained inside the cam phaser, the result can be poor engine performance at specific engine speeds and loads. In many cases, a DTC will be stored that indicates a problem in the VVT system.

Adding it All Up

Since oil prices have climbed dramatically the past few years, customers are becoming more price-sensitive. But it’s also important to understand that, to remain profitable, a shop’s pricing structure for modern vehicle oil change and inspection intervals must be realistic.

In addition, you’re doing a disservice to your customers if you’re exclusively selling low-cost generic engine oils and budget-priced oil filters to meet price-sensitive competition.

OE-specification oils and filters often become the cheaper (and wiser) choice when weighed against a costly engine replacement. If you do the math, it will become clear to you and your customer that using the correct engine oil and filter is the less expensive and far more prudent choice.

Focus on Filters

Filters, too, have long been a common maintenance item. But with longer factory service intervals and “lifetime” filters becoming more common, how often do filters really need to be replaced?

There’s no simple answer. The safest advice used to be to follow the filter service interval recommendations in the vehicle owner’s manual (assuming the owner’s manual hasn’t been lost and that somebody will actually read it!). The problem with this recommendation is that some filters no longer have a service interval (such as most fuel and transmission filters), and the factory recommended service intervals for some filters and fluids (motor oil and filter for example) may be overly optimistic and don’t take into account the kind of driving many motorists actually do.

The purpose of a filter is to trap abrasive particles before they can do any harm. That’s true of air filters, oil filters, fuel filters and transmission filters. As for cabin air filters, their purpose can be two-fold: to keep dirt and grit out of the HVAC system and passenger compartment, and to absorb and trap unpleasant odors before they enter the vehicle (in the case of dual-purpose cabin air filters). All filters, even “lifetime” ones, have a limited service life and eventually become clogged with dirt, wear particles, rust or whatever. So, the idea behind preventive maintenance is to change the filter before it reaches that point.

The most often replaced filter is the oil filter. It usually gets changed every 3,000 to 7,500 miles on most vehicles (except in Europe where they use different motor oils and typically go for a once-a-year oil change). On many late-model vehicles, oil change intervals have been extended from the traditional 3,000 miles or 6 months, to 5,000 to 7,500 miles or more.

On vehicles that employ a maintenance reminder light to signal when an oil change is needed, the reminder light may not come on for up to 15,000 miles or more depending on all the operating variables the software considers when making its estimate. On some vehicles, additional input from an electrical sensor in the oil pan may help detect oil that is breaking down or is heavily contaminated with moisture.

An important point to keep in mind with respect to extended oil change intervals is that many of these intervals are based on using high-quality synthetic motor oil rather than conventional motor oil, and a premium-quality oil filter which typically use a synthetic media that outperforms most conventional cellulose filter media.

Air filters also have much longer replacement intervals these days — assuming the motorist is not driving in an extremely dusty environment or on rural gravel roads. The typical factory recommended service interval for many air filters these days is typically 30,000 to 50,000 miles. On 2004 to 2011 Ford Focus PZEV models, the factory air filter is supposed to have a service life of up to 150,000 miles. And then you have to replace the entire housing with the filter sealed inside of it when a change is needed.

A more realistic recommendation for air filter service is to inspect it at least once a year or at every oil change, and to replace as needed even if the factory service interval has not yet been reached.