Models: All

Models: All

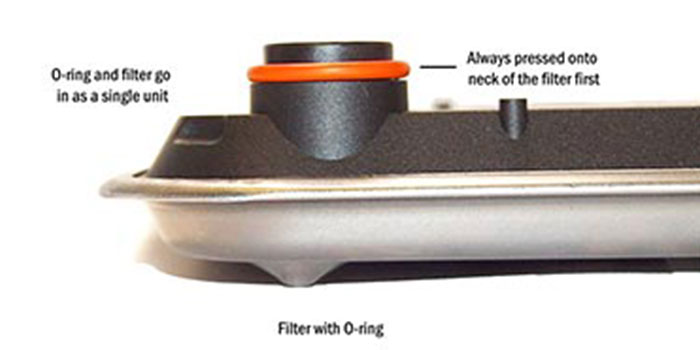

Many transmission filters require a seal at the point where they assemble into the transmission. Most of these seals are called “lip seals,” although some filters may use an O-ring.

Before filter installation, it is important to make sure that there is no O-ring or lip seal in the case or pump bore left over from the old filter.

O-rings are placed on the filter tube (as far as they will go) prior to filter installation. Put transmission fluid or lube on the O-ring and assemble the filter tube into the case or pump bore with an upward motion until completely seated.

There are two distinct types of lip seals, and the way in which these are used is entirely different. Installing the lip seal using the wrong procedure can actually cause complete transmission failure in a short time, so it is very important to understand the difference between the two and the proper installation procedure for each.

The first type of seal is a round, ribbed band, which is pressed onto the filter outlet tube as far as it will go. There are stops or flanges on the filter tube where these lip seals are meant to rest. This type of lip seal usually comes assembled to the filter and is always pressed onto the filter tube before the filter is assembled into the transmission.

The other type of lip seal, largely used on General Motors transmissions, is never assembled to the filter tube. It must always be press fit into the transmission first and then the filter inserted into the already installed lip seal. This type of lip seal is shaped somewhat like a hat, as it really does have a lip or flange on one end. Lubricate and then insert this type lip seal into the transmission assembly. It will be an extremely tight fit. Make sure the seal is square to the hole and tap it in carefully. The seal must be fully seated in the hole right up to the lip. Then, using more transmission lube, assemble the filter into the seal with an upward twisting motion. Failure to follow this procedure can damage the rubber end of the seal. Immediate transmission failure will occur if a piece of this rubber seal can get to the pump.

Courtesy of Filter Manufacturers Council.